A preparation method of all-silicon amorphous porous material and its application in cigarette filter

A technology of porous materials and cigarette filters, applied in applications, e-liquid filter elements, chemical instruments and methods, etc., can solve problems such as inability to achieve adsorption effects, achieve easy large-scale production, high feasibility, and reduce the content of irritating substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

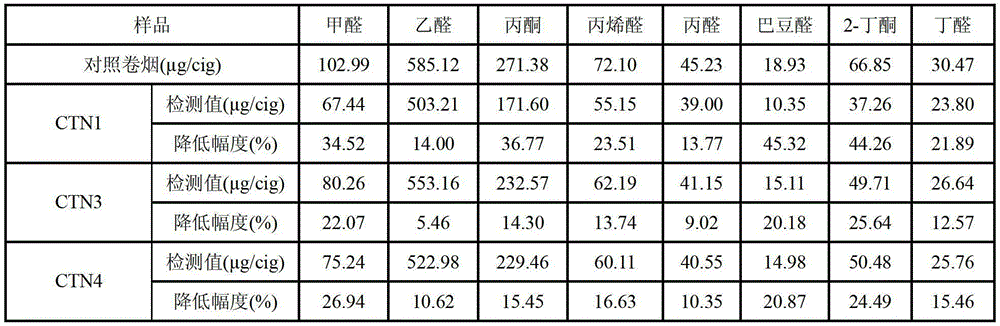

Examples

Embodiment 1

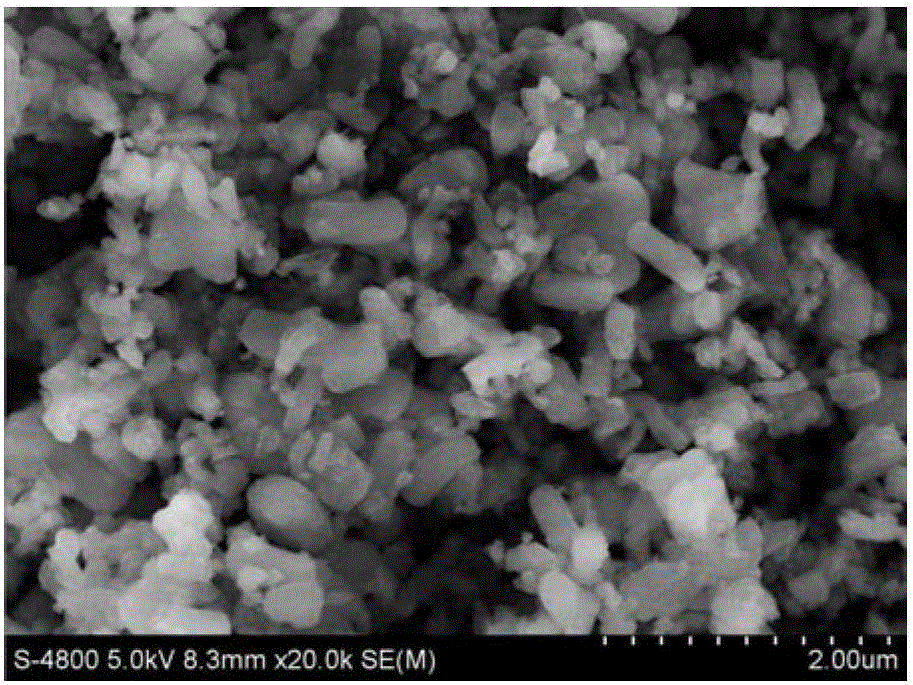

[0034] 1. Preparation of all-silicon amorphous porous material by hydrothermal synthesis method: 0.25g of cetyltrimethylammonium bromide (CTAB) was completely dissolved in 35g of deionized water, which was recorded as solution A; 10g of diethyl ether and 1.2g Mix tetraethyl silicate (TEOS) evenly, gradually add 20mL of 0.2mol / L hydrochloric acid solution dropwise, and 14-16% TEOS is pre-hydrolyzed, which is recorded as solution B. Under vigorous stirring, solution B was added dropwise into solution A, and then the solution was adjusted to pH 9.0 with 0.5M sodium carbonate. The formed sol was transferred to an airtight container, stirred at room temperature for 12 h, and then aged at 100° C. for 24 h. The reaction product was filtered, washed thoroughly with deionized water, and dried in air for 15 h to powder. Calcined under nitrogen at 550°C for 5 hours to obtain a porous material, which is designated as CTN1. The specific surface area and pore structure data of CTN1 are sh...

Embodiment 2

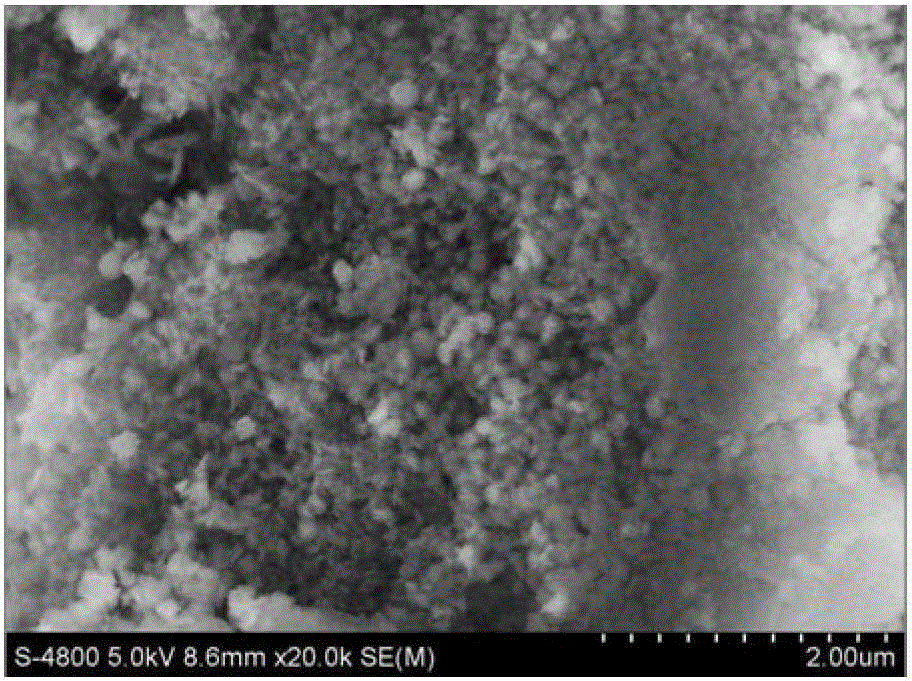

[0047] 1. Preparation of all-silicon amorphous porous material by hydrothermal synthesis method: completely dissolve 0.25g cetyltrimethylammonium bromide (CTAB) in 35g deionized water, which is recorded as solution A; mix 10g methyl ethyl ether and 1.75 g of silica sol, and gradually add 5mL of 0.2mol / L phosphoric acid solution dropwise to achieve pre-hydrolysis of 14-16% TEOS, which is recorded as solution B. Under vigorous stirring, solution B was added dropwise into solution A, and then the solution was adjusted to pH 12.0 with 0.1 M NaOH solution. The formed sol was transferred to an airtight container, stirred at room temperature for 10 h, and then aged at 120 °C for 20 h. The reaction product was filtered, washed thoroughly with deionized water, and dried in air for 20 h to powder. Calcined with oxygen at 600°C for 8 hours to obtain a porous material, denoted as CTN2. The specific surface area and pore structure data of CTN2 are shown in Table 2, and the scanning elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com