Method for aluminum ash treatment and recycling use

A technology of aluminum ash and aluminum liquid, which is applied in the field of aluminum ash treatment and recycling, can solve the problems of increasing the dust removal system and waste multiple utilization processes, resource waste costs, environmental pollution, etc., achieving significant economic benefits, improving production efficiency, The effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

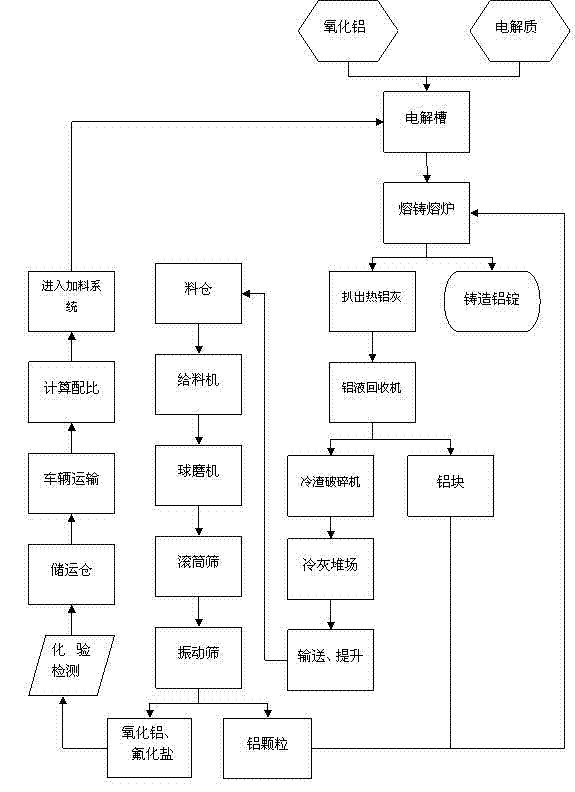

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the implementation manners of the present invention will be further described in detail below.

[0018] A method for aluminum ash treatment and recycling, the method comprises the following steps:

[0019] a. In a dust-proof and airtight environment, pour the hot aluminum ash extracted from the melting and casting furnace into the reaction kettle of the molten aluminum recovery machine, add slagging agent into the reaction kettle, and start the stirring of the molten aluminum recovery machine Blades, after fully stirring, send the recycled aluminum into the melting and casting furnace, leaving waste slag;

[0020] b. In a dust-proof and airtight environment, send the waste slag in step a to the cold slag crusher for crushing, and send the crushed cold slag to the cold ash storage yard;

[0021] c. In a dust-proof environment, the cold ash in the cold ash storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com