Method for reducing defects on aluminum gasket surface

A liner and defect technology, which is applied in the field of reducing aluminum liner surface defects, can solve problems such as peeling, limit application range, and affect electrical performance, and achieve the effects of easy stress release, whisker-shaped defects, and good step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

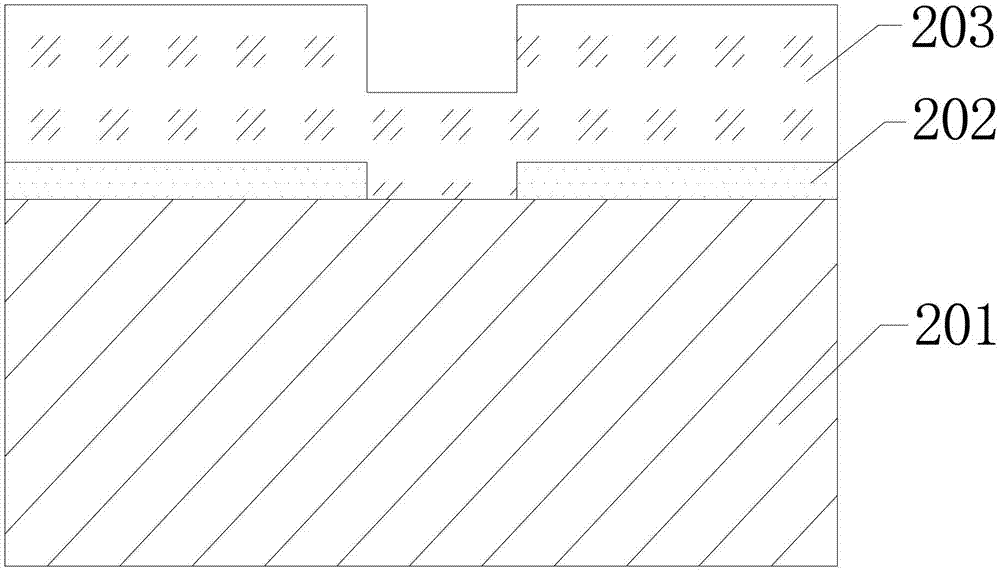

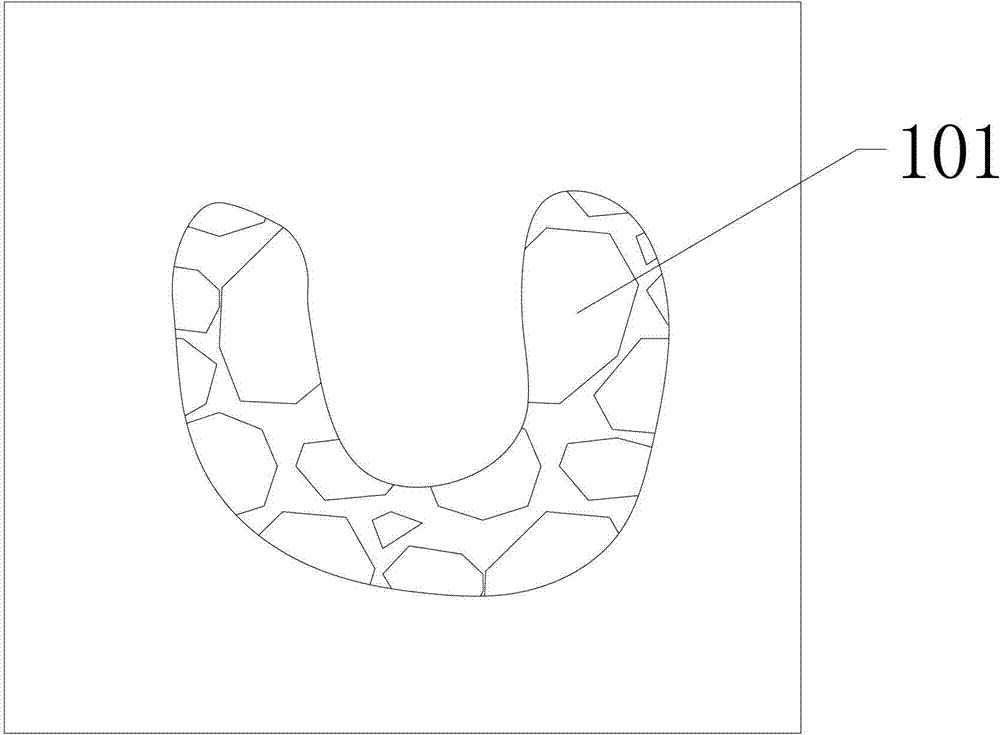

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

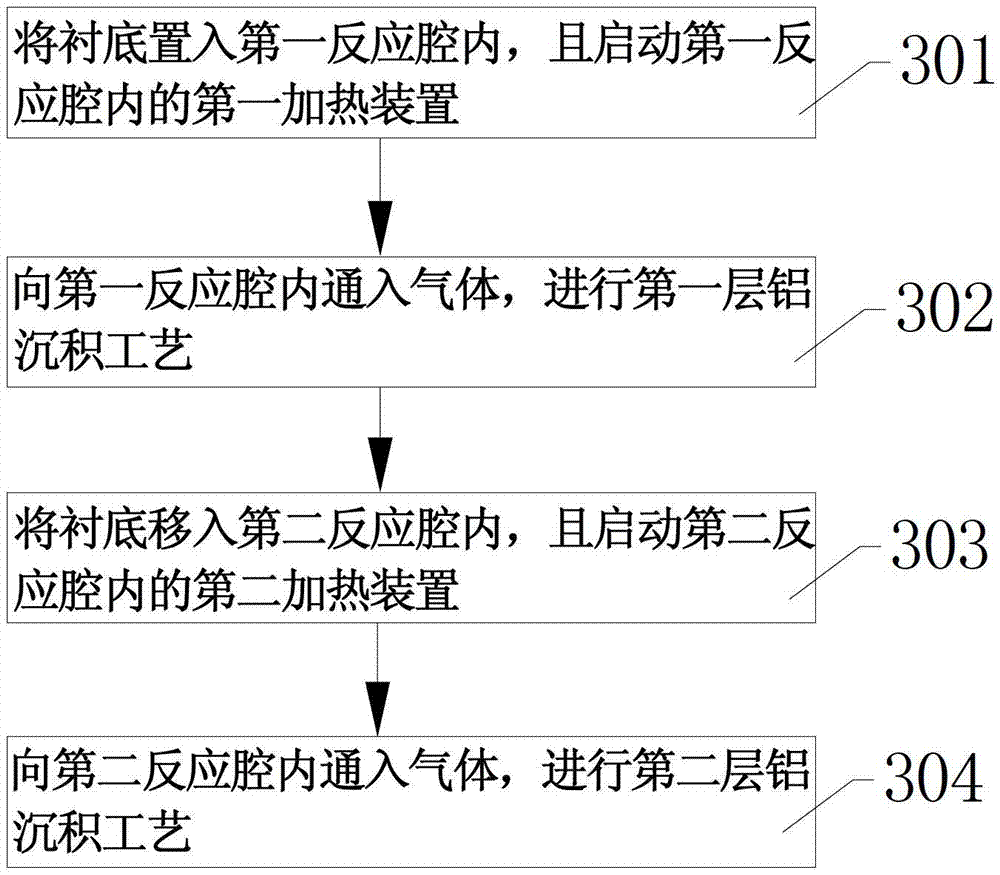

[0038] image 3 It is a schematic diagram of the process of depositing aluminum liner of the present invention, such as image 3 As shown,

[0039] Step 301: Place the substrate in the first reaction chamber, start the first heating device in the first reaction chamber, and control the temperature T in the first reaction chamber 1 At 100℃≤T 1 ≤220℃, such as 100℃, 150℃, 220℃, etc., and the best temperature is 200℃;

[0040] Step 302: Pour gas into the first reaction chamber to reduce the direct current power P applied to the first aluminum target 1 Control at 28KW≤P 1 ≤35KW, such as 28KW, 32KW, 35KW, etc., and the best DC power is 30KW, perform the first aluminum deposition process, and prepare the first aluminum layer on the upper surface of the substrate;

[0041] Step 303: Move the substrate with the first aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com