Method for preparing porous hydroxyapatite scaffold via two-step process

A technology of porous hydroxyapatite and hydroxyapatite, which is applied in the field of biomedical materials, can solve the problems of complex process and long preparation cycle, and achieve the effect of low residual content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

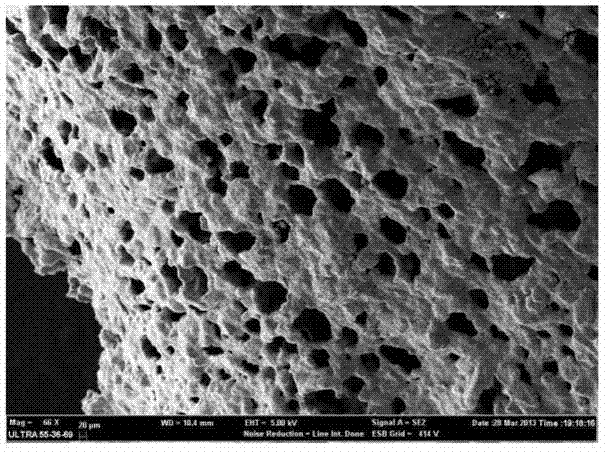

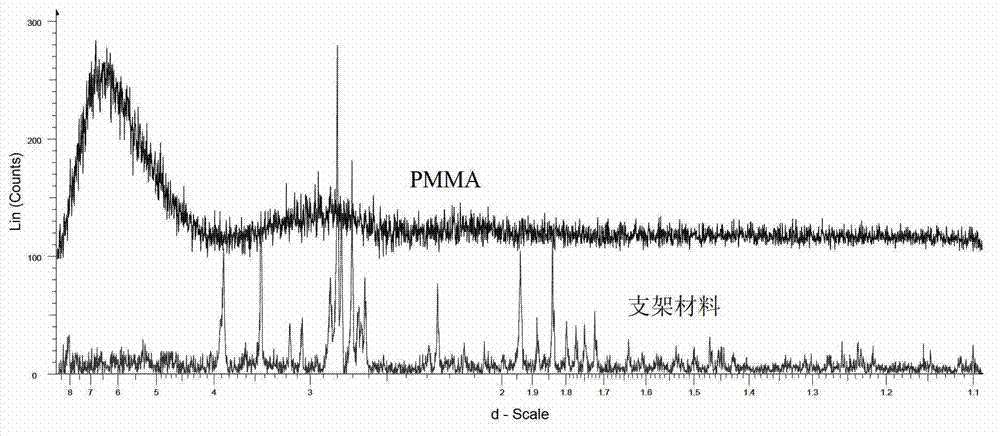

[0022] Such as figure 1 As shown, this embodiment includes:

[0023] Step 1, weigh hydroxyapatite, PMMA, SDS and ammonium bicarbonate according to the ratio of 8:6:11:3;

[0024] Step 2, putting hydroxyapatite, PMMA and SDS into a glass container, stirring evenly with a machine;

[0025] Step 3, dissolving ammonium bicarbonate in ultrapure water at a ratio of 1:1;

[0026] Step 4, drop the ammonium bicarbonate solution into the mixed powder, and stir evenly;

[0027] Step 6, put in an oven, dry at 70°C, take out the block after drying, and put it in a crucible;

[0028] Step 7, put the crucible into a high-temperature heating furnace, and raise the temperature to 600°C at 2°C / min for 2 hours;

[0029] Step 8, continue to heat up at 2°C / min to 1000°C for 2 hours;

[0030] Step 9, taking out the crucible after cooling with the furnace to obtain a porous hydroxyapatite support.

Embodiment 2

[0032] Step 1, weigh hydroxyapatite, PMMA, SDS and ammonium bicarbonate according to the mass ratio of 8:5:10:2;

[0033] Step 2, put hydroxyapatite, PMMA and SDS into a glass container, and mechanically stir evenly;

[0034] Step 3, dissolving ammonium bicarbonate in ultrapure water at a ratio of 1:0.75;

[0035] Step 4, drop the ammonium bicarbonate solution into the mixed powder, and stir evenly;

[0036] Step 6, put in an oven, dry at 60°C, take out the block after drying, and put it in a crucible;

[0037] Step 7, put the crucible into a high-temperature heating furnace, and raise the temperature to 600°C at 2°C / min for 2 hours;

[0038] Step 8, continue to heat up at 2°C / min to 1300°C for 2 hours;

[0039] Step 9, taking out the crucible after cooling with the furnace to obtain a porous hydroxyapatite support.

Embodiment 3

[0041] Step 1, weigh hydroxyapatite, PMMA, SDS and ammonium bicarbonate according to the ratio of 8:6:11:3;

[0042] Step 2, putting hydroxyapatite, PMMA and SDS into a glass container, stirring evenly with a machine;

[0043] Step 3, dissolving ammonium bicarbonate in ultrapure water at a ratio of 1:1;

[0044] Step 4, drop the ammonium bicarbonate solution into the mixed powder, and stir evenly;

[0045] Step 6, put in an oven, dry at 70°C, take out the block after drying, and put it in a crucible;

[0046] Step 7, put the crucible into a high-temperature heating furnace, and raise the temperature to 400°C at 2°C / min for 2 hours;

[0047] Step 8, continue to heat up at 2°C / min to 1100°C for 2 hours;

[0048] Step 9, taking out the crucible after cooling with the furnace to obtain a porous hydroxyapatite support.

[0049] To sum up, the present invention greatly improves the strength and toughness of the prepared scaffold material through targeted high-temperature sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com