Preparation method of polyacid-like late transition metal-organic network catalyst material

A late-transition metal-organic network technology, applied in the field of preparation of late-transition metal-organic network catalyst materials, can solve problems such as shedding and difficulty in controlling synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

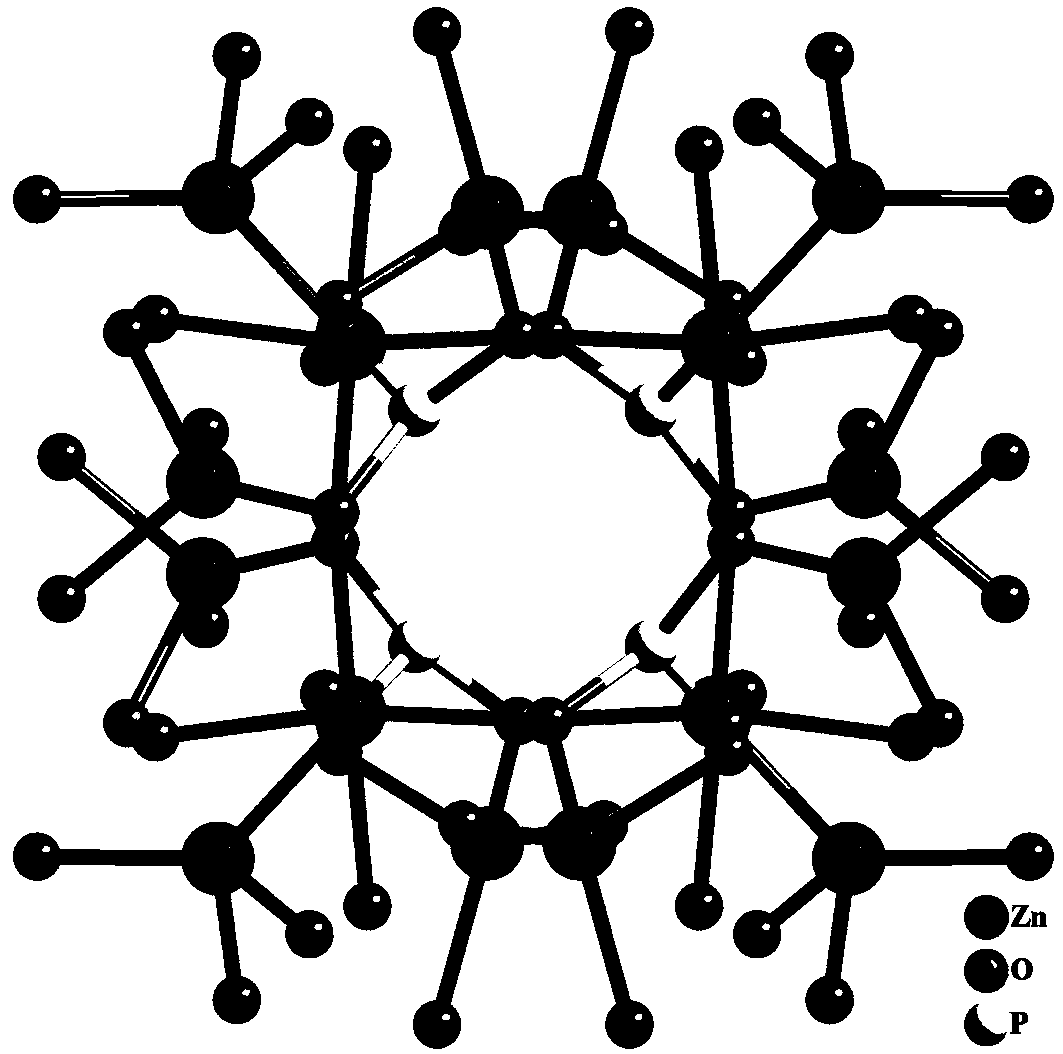

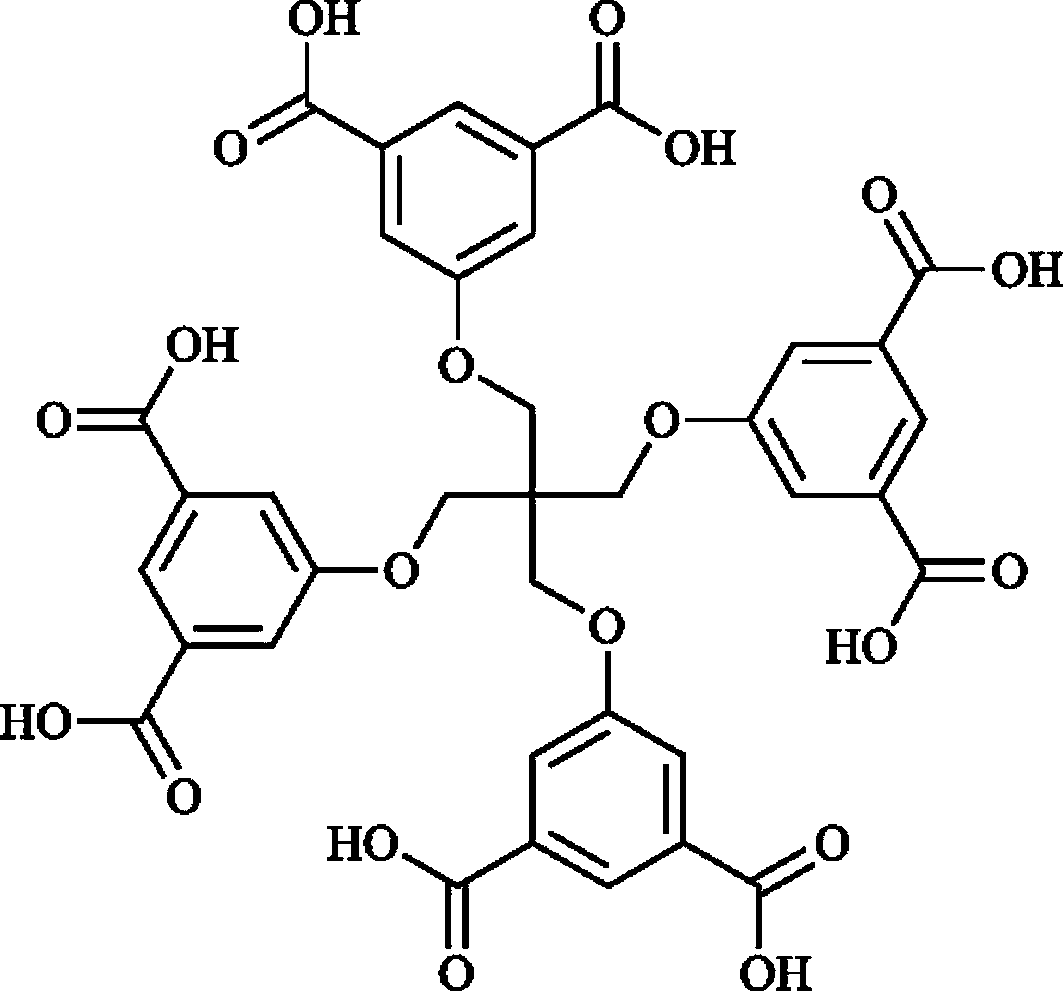

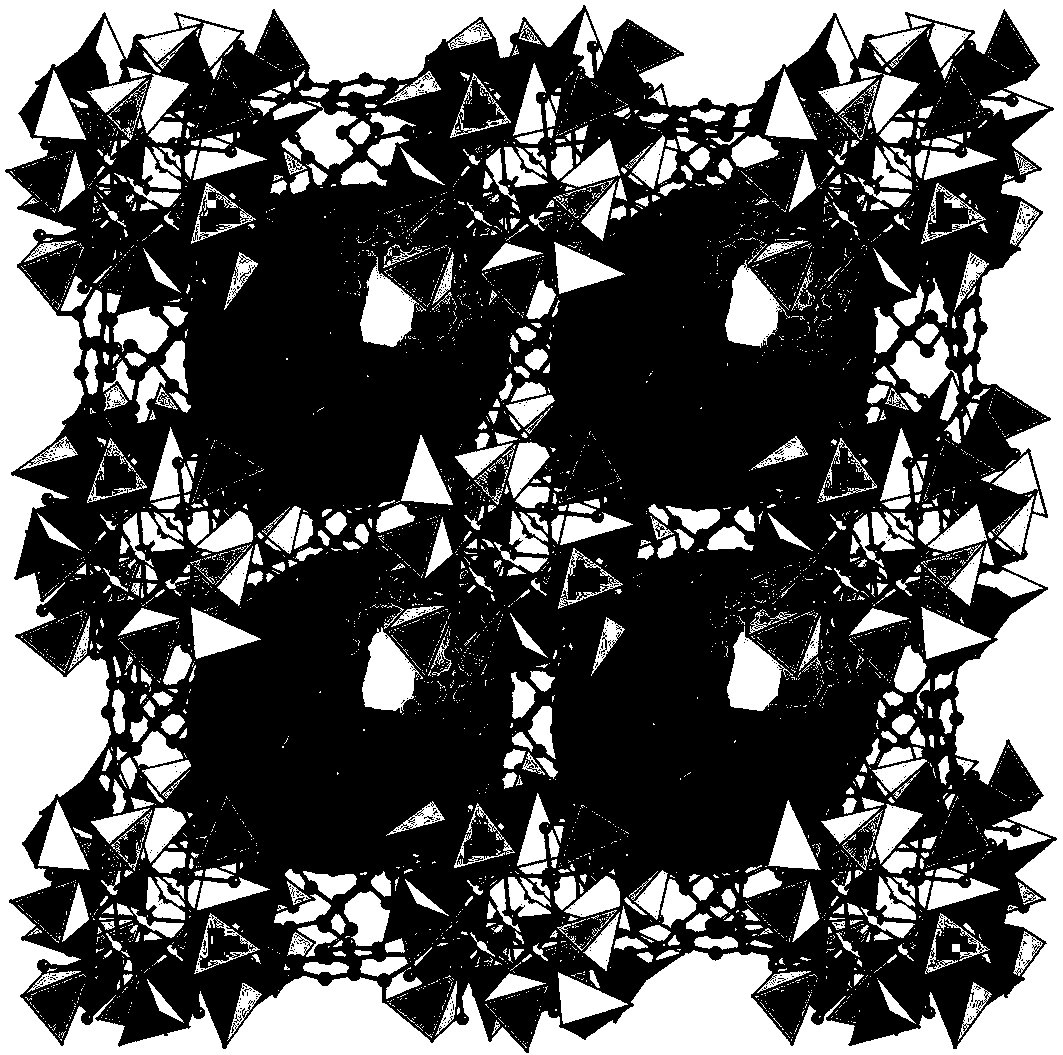

[0019] A late-transition metal-organic network catalyst material of a class of polyacids, the chemical composition of which is: [Zn 16 (HPO 3 ) 4 ] L 3 .

[0020] Preparation method: Grind molybdate and molybdenum powder evenly at a molar ratio of 5:1, add zinc salt, phosphorous acid, organic bridging ligand and water (10 ml), and stir for 15 minutes. Then adjust the pH of the mixture to 5 with dilute hydrochloric acid, put it into a high-pressure reactor, raise the temperature to 180°C at a rate of 1-5°C / min, keep it warm for 48 hours, and then cool it down to room temperature at a rate of 1-5°C / min , and the catalyst was obtained by filtration.

Embodiment 2

[0022] A late-transition metal-organic network catalyst material of a class of polyacids, the chemical composition of which is: [Cd 16 (HPO 3 ) 4 ] L 3 .

[0023] Preparation method: Grind molybdate and molybdenum powder evenly at a molar ratio of 5:1, add cadmium salt, phosphorous acid, organic bridging ligand and water (10 ml), and stir for 30 minutes. Then adjust the pH value of the mixture to 4 with dilute hydrochloric acid, put it into a high-pressure reactor, raise the temperature to 180°C at a rate of 1-5°C / min, keep it warm for 72 hours, and then lower it to room temperature at a rate of 1-5°C / min , and the catalyst was obtained by filtration.

Embodiment 3

[0025] A late-transition metal-organic network catalyst material of a class of polyacids, the chemical composition of which is: [Cu 16 (HPO 3 ) 4 ] L 3 .

[0026] Preparation method: Grind molybdate and molybdenum powder evenly at a molar ratio of 5:1, add copper salt, phosphorous acid, organic bridging ligand and water (10 ml), and stir for 60 minutes. Then adjust the pH of the mixture to 6 with dilute hydrochloric acid, put it into a high-pressure reactor, raise the temperature to 180°C at a rate of 1-5°C / min, keep it warm for 60 hours, and then lower it to room temperature at a rate of 1-5°C / min. The catalyst was obtained by filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com