Method for preparing block copolymer proton exchange membrane through controlling over free radical polymerization under existence of DPE

A technology of block copolymer and proton exchange membrane, applied in the field of preparation of proton exchange membrane, can solve the problems of molecular design and structural regulation limitation of proton exchange membrane, achieve green polymerization system, improve proton conductivity and monomer conversion rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

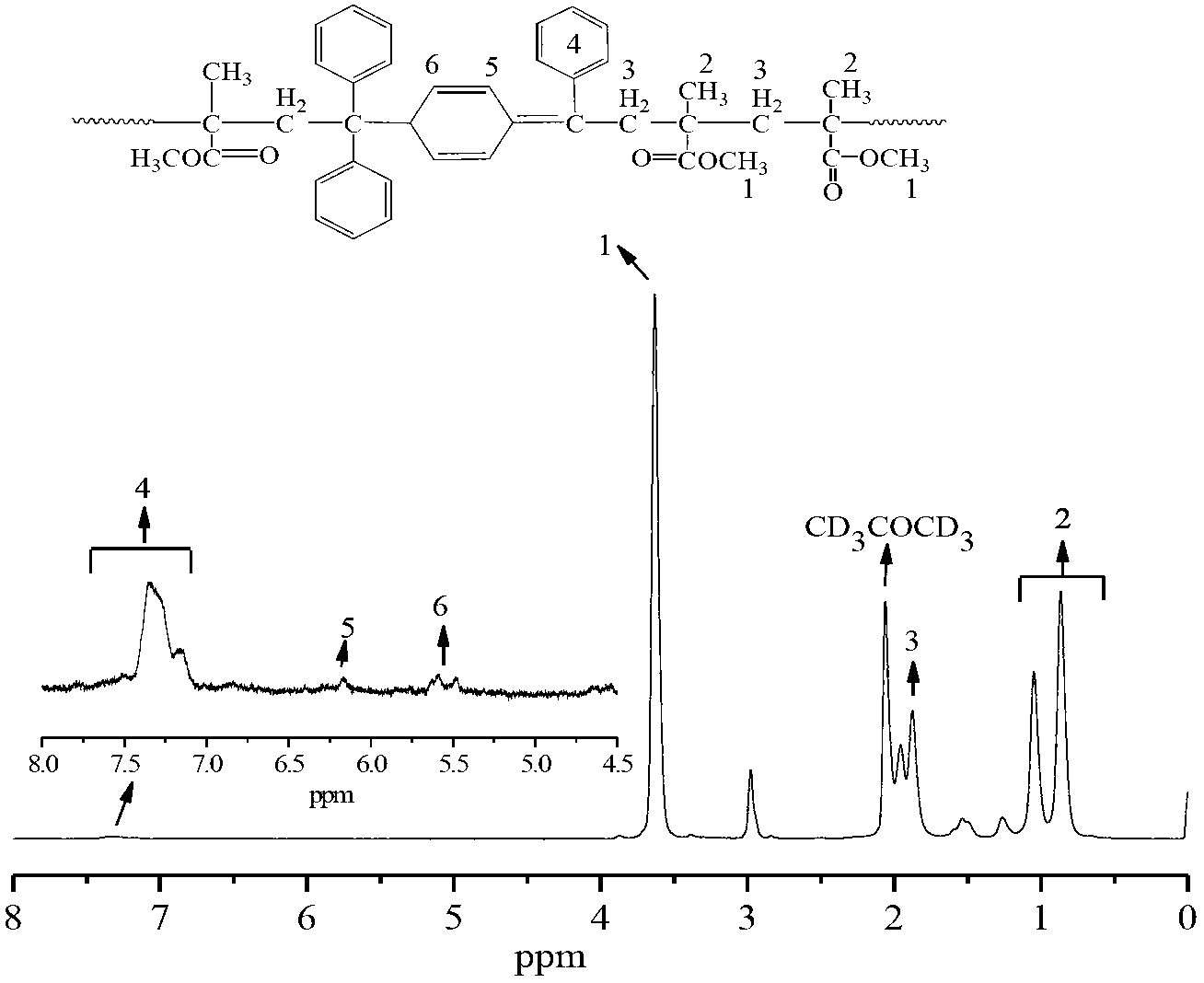

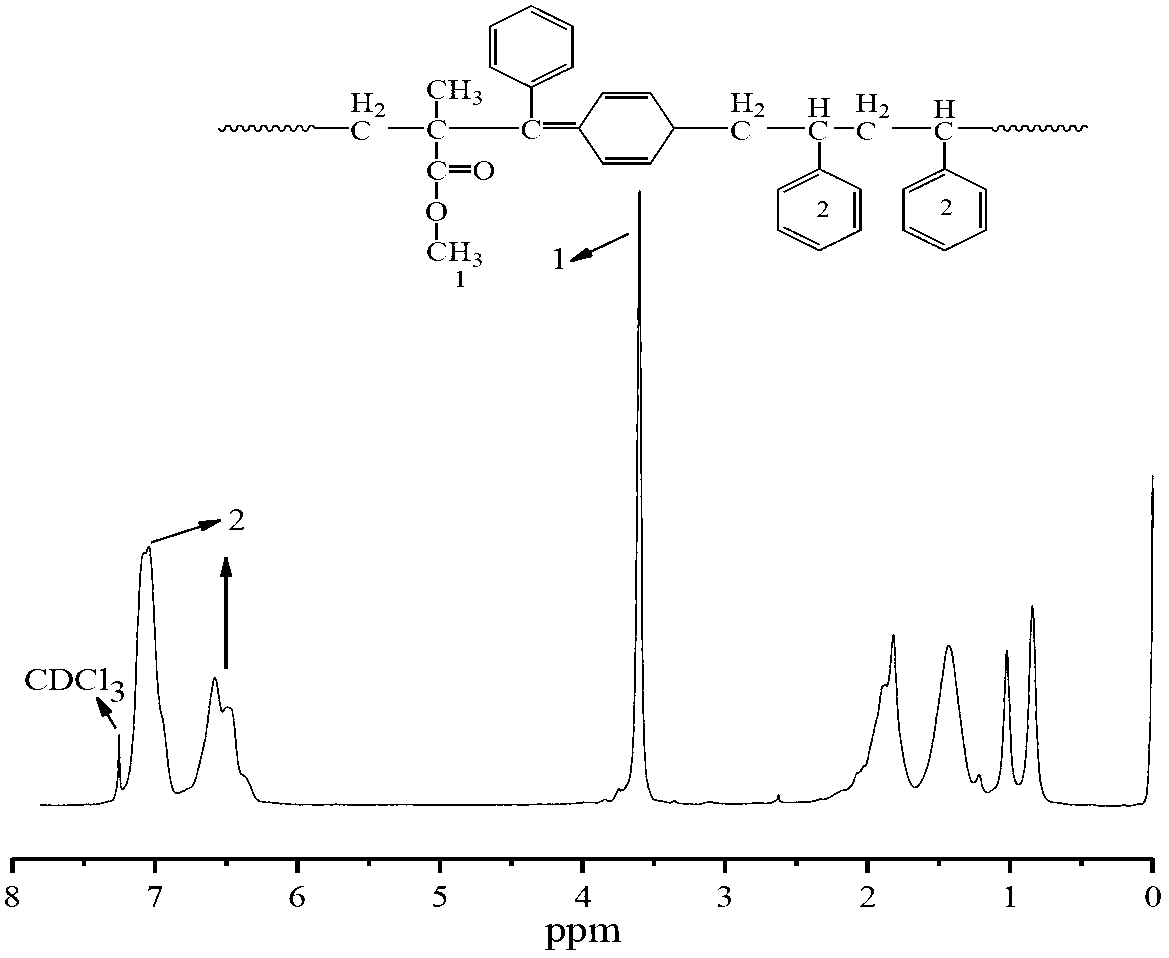

[0031] Example 1: Controlled free radical polymerization in the presence of DPE to prepare block copolymer proton exchange membrane, using sodium dodecylbenzenesulfonate as surfactant

[0032]30g of sodium dodecylbenzenesulfonate aqueous solution with a mass fraction of 0.25% was added to a 150ml three-necked flask equipped with an electric stirrer and a condenser, and 8g of methyl methacrylate and 0.12g of 1,1-diphenyl Add ethylene into the above-mentioned three-necked flask, and pre-emulsify under 300r / min mechanical stirring. After 30 minutes, put the three-neck flask in an 80°C water bath, and after equilibrating for 10 minutes, add 10 g of potassium persulfate aqueous solution with a mass fraction of 14% to the emulsion system, continue the reaction for 6 hours, and then cool to room temperature to obtain seeds containing macromolecular precursors latex. Using a dropping funnel, 5 g of styrene and 10 g of 0.3% sodium dodecylbenzenesulfonate aqueous solution were added dr...

Embodiment 2

[0034] Example 2: Controlled free radical polymerization in the presence of DPE to prepare block copolymer proton exchange membrane, using sodium dodecylsulfonate as surfactant

[0035] Add 30 g of sodium dodecylsulfonate aqueous solution with a mass fraction of 0.3% into a 150 ml three-necked flask equipped with an electric stirrer and a condenser, mix 8 g of methyl methacrylate and 0.2 g of 1,1-diphenylethylene Add it into the above-mentioned three-necked flask, and pre-emulsify under 300r / min mechanical stirring. After 30 minutes, put the three-neck flask in an 80°C water bath, and after equilibrating for 10 minutes, add 10 g of potassium persulfate aqueous solution with a mass fraction of 18% to the emulsion system, continue the reaction for 6 hours, and then cool to room temperature to obtain seeds containing macromolecular precursors latex. Using a dropping funnel, 5 g of styrene and 10 g of 0.3% sodium dodecylsulfonate aqueous solution were added dropwise at the same t...

Embodiment 3

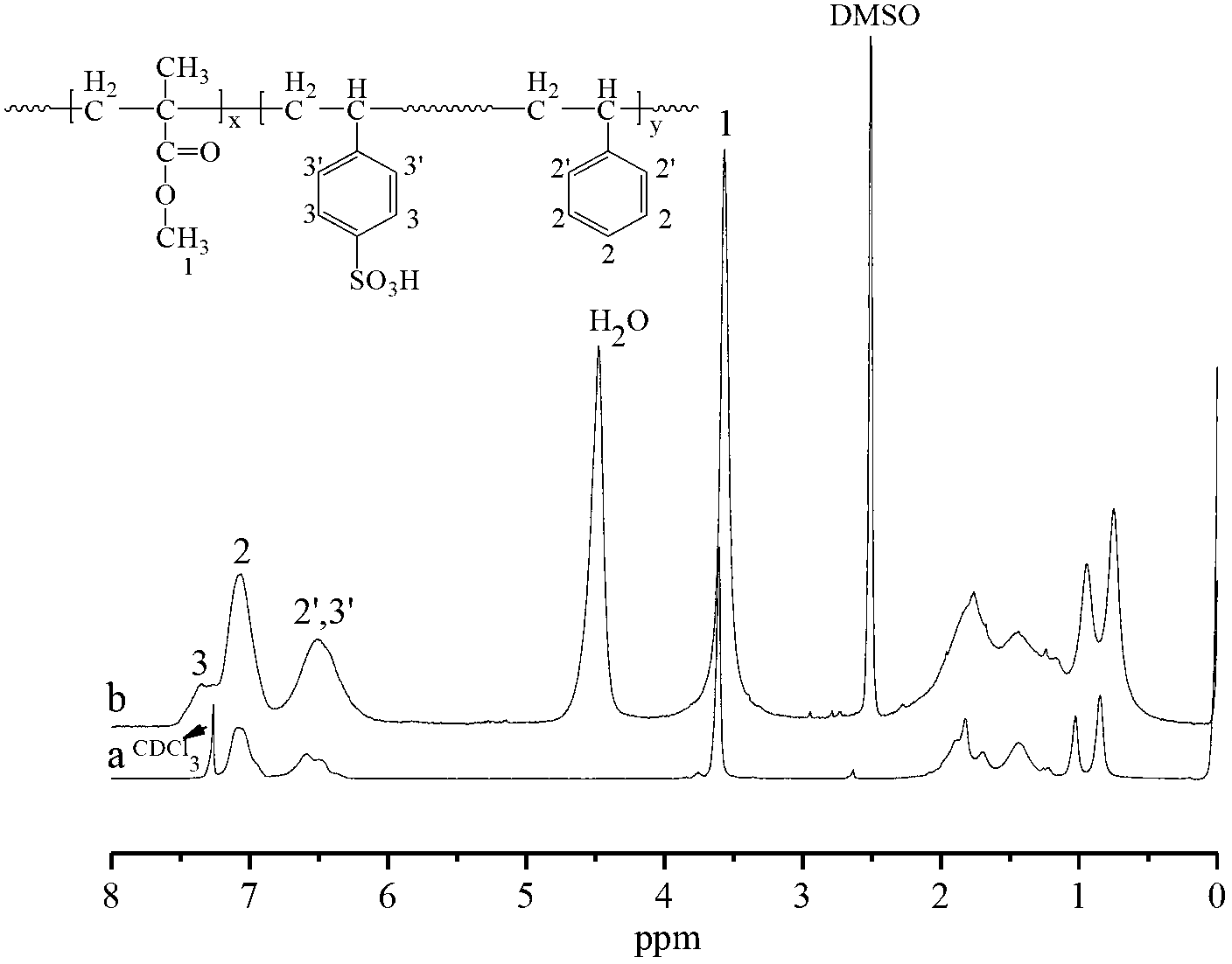

[0037] Example 3: Controlled free radical polymerization in the presence of DPE to prepare block copolymer proton exchange membrane, the sulfonation time is 130min

[0038] Add 30 g of sodium dodecylsulfonate aqueous solution with a mass fraction of 0.3% into a 150 ml three-necked flask equipped with an electric stirrer and a condenser, mix 8 g of methyl methacrylate and 0.2 g of 1,1-diphenylethylene Add it into the above-mentioned three-necked flask, and pre-emulsify under 300r / min mechanical stirring. After 30 minutes, put the three-neck flask in an 80°C water bath, and after equilibrating for 10 minutes, add 10 g of potassium persulfate aqueous solution with a mass fraction of 18% to the emulsion system, continue the reaction for 6 hours, and then cool to room temperature to obtain seeds containing macromolecular precursors latex. Using a dropping funnel, 5 g of styrene and 10 g of 0.3% sodium dodecylsulfonate aqueous solution were added dropwise at the same time. Under me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com