Multilayer tubular structural cell culture bracket as well as preparation method and use thereof

A cell culture, tubular structure technology, applied in the multi-layer tubular structure cell culture scaffold and its preparation, the field of three-dimensional tubular structure with single or multiple cells layered distribution, can solve the influence of the tubular structure, long culture time, impossible Realize the controllable distribution and growth of a variety of cells, and achieve the effect of obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

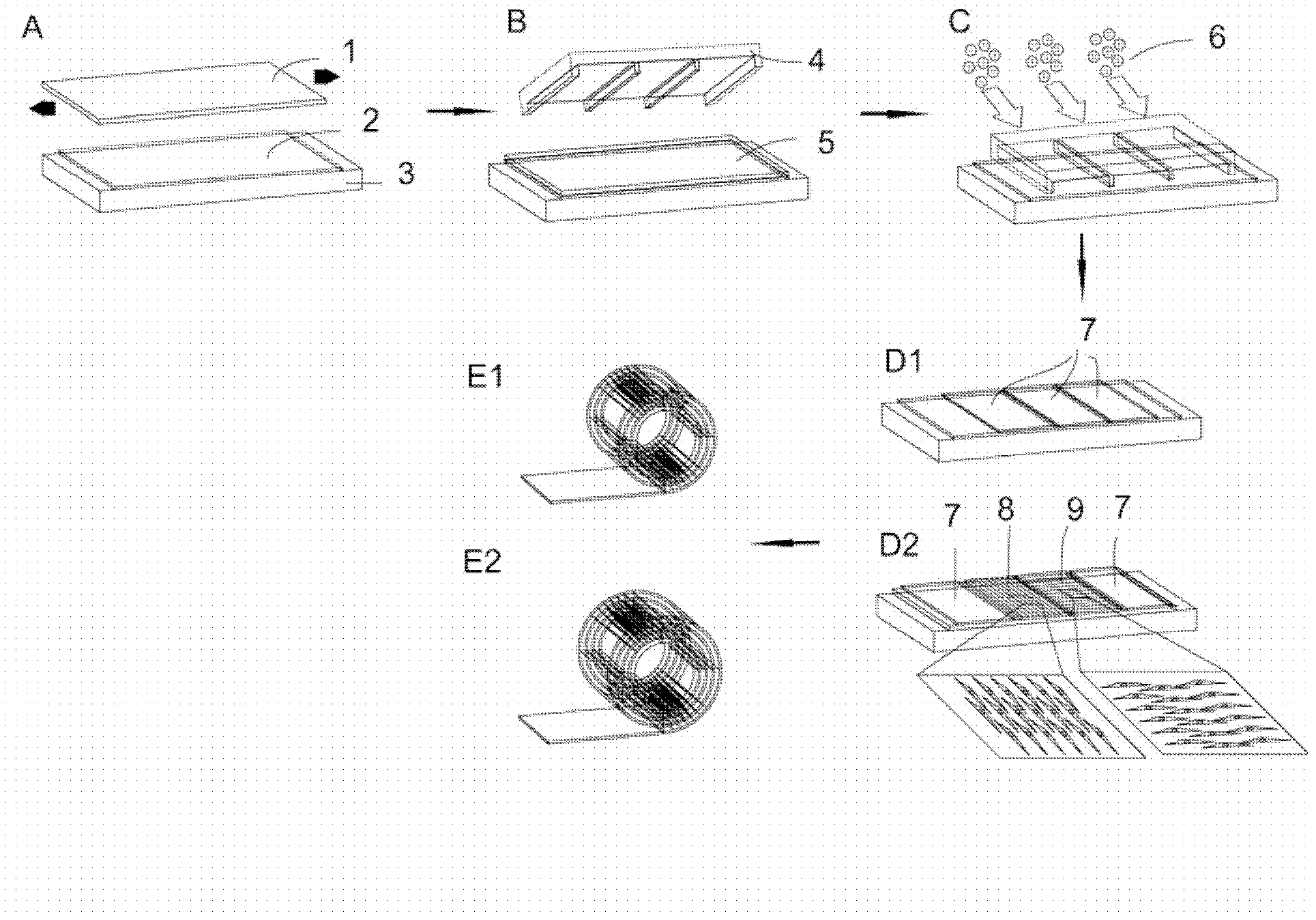

[0057] The preparation of PDMS self-curling film (i.e., multi-layer tubular structure cell culture scaffold) is as follows:

[0058] (1) Preparation of polymer elastic film layer, i.e. PDMS thin film: Prepolymer and curing agent are prepared according to the ratio of 10:1 PDMS prepolymer reaction liquid, and spin-coated on the surface of smooth single crystal silicon wafer in the glue homogenizer, The rotating speed is 3000rpm, and the time is 30s. Place in a blast drying oven and bake at 150°C for 15 minutes, then take it out of the oven.

[0059] (2) Preparation of polymer immobilized layer: spin-coat the reaction solution of PDMS prepolymer (the same as the PDMS prepolymer in the above steps) on the surface of a clean glass slide in a homogenizer, the speed is 6000rpm, and the time is 60s . Put it in a blast drying oven and bake at 80°C for 4 minutes, then take it out of the oven. It is required that the PDMS prepolymer reaction solution on the surface of the glass slide ...

Embodiment 2

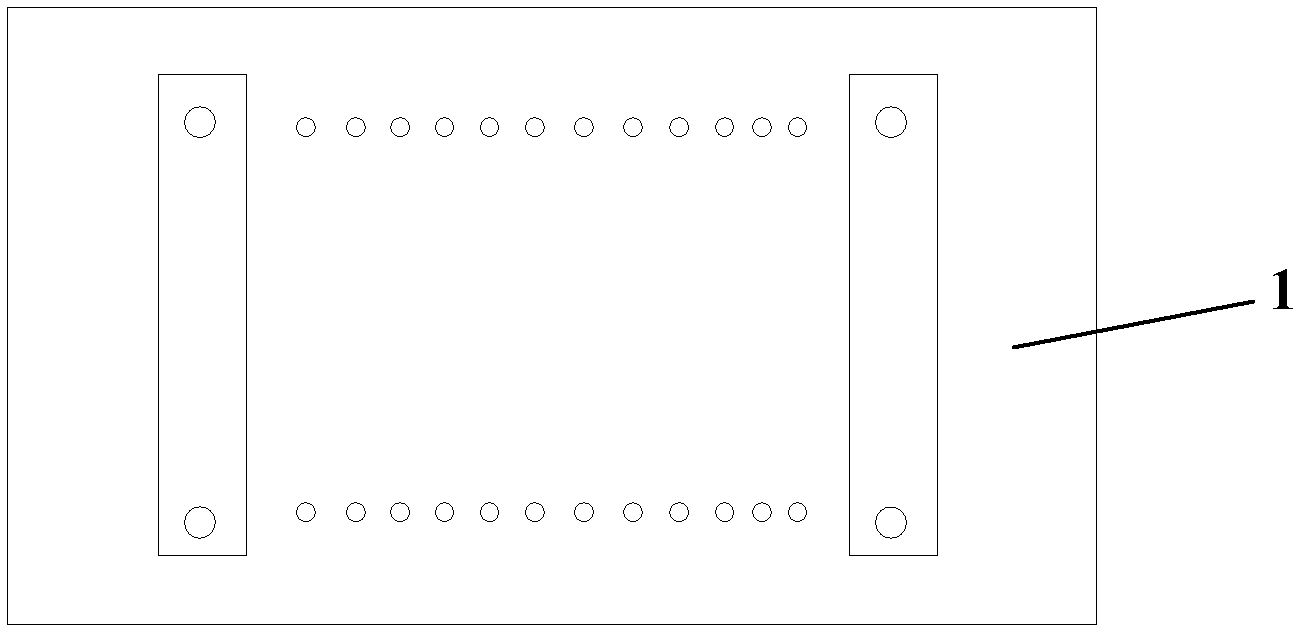

[0063] The preparation of the self-rolling film (that is, multi-layer tubular structure cell culture support) with porous structure, the specific steps are as follows:

[0064] (1) Preparation of a polymer elastic film layer with a porous structure, that is, a PDMS film: the first is the preparation of the template, the main process is photolithography, that is, using the characteristics of photoresist that can change properties under ultraviolet irradiation on a single crystal silicon wafer A columnar microarray is prepared, the columnar diameter is adjustable from 1 micron to 10 mm, and the height is adjustable from 0.1 micron to 1 mm. The photolithography template needs to be used after perfluorosilane treatment. The second is the preparation of porous PDMS film. The method is soft etching technology. The PDMS prepolymer reaction solution is spin-coated on the photolithographic template in a homogenizer. After heating for 5 minutes, take it out, and carefully peel off the ...

Embodiment 3

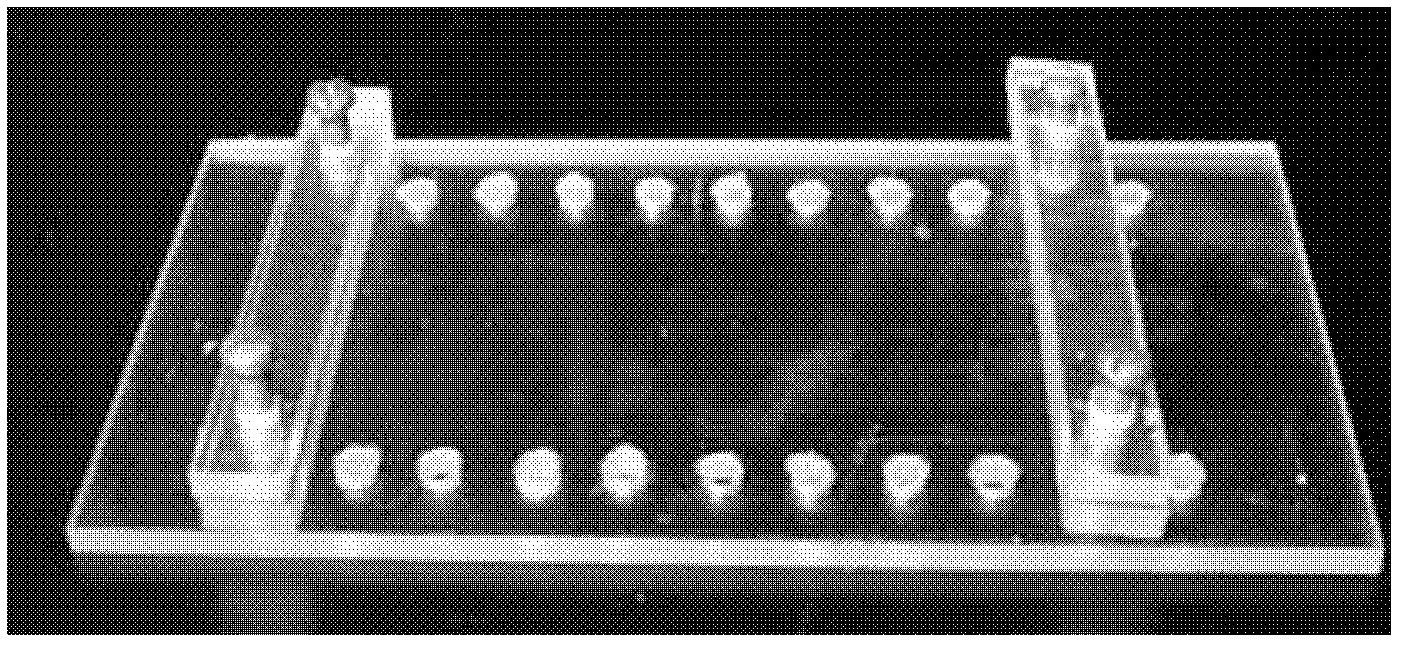

[0069] The preparation of the PDMS self-curling film (that is, a multilayer tubular structure cell culture support) with a microgroove structure in the polymer immobilization layer, the specific steps are as follows:

[0070] (1) Preparation of polymer elastic film layer, i.e. PDMS thin film: PDMS prepolymer and curing agent are prepared according to the ratio of 10:1 PDMS prepolymer reaction solution, and spin-coated on the surface of smooth single crystal silicon wafer in a glue homogenizer , the rotational speed is 2000rpm, and the time is 60s. Put it in a blast drying oven and bake at 150°C for 5 minutes, take it out of the oven, and peel off the PDMS film from the silicon wafer.

[0071](2) Preparation of a polymer fixed layer with a microgroove structure: first, the preparation of the template, the main process is photolithography, that is, using the characteristics of photoresist that can change properties under ultraviolet irradiation to prepare a raised cuboid array o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com