Preparation method of nano Al/ RDX energy-containing composite particles with core-shell structures

A composite particle, shell structure technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy oxidation of nanometer Al, and achieve the improvement of compatibility, prevention of oxidation, and improvement of activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

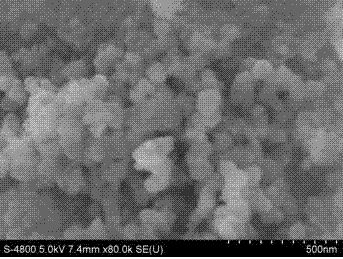

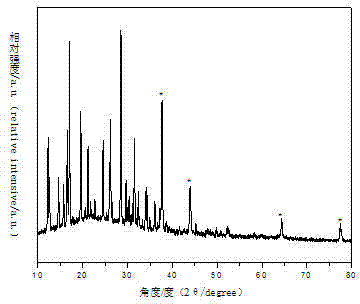

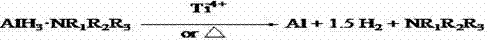

[0035] A preparation method of nano Al / RDX core-shell structure energetic composite particles, the steps are as follows:

[0036] 1. At room temperature, add 0.005mol anhydrous AlCl 3 Dispersed in 60ml of toluene solution, under vigorous stirring, 0.02mol of N(Et) 3 Add to AlCl at a rate of 1-2 drops / sec 3 in the toluene solution. AlCl to be solid 3 After dissolving, slowly add 0.0015mol LiAlH 4 Add it into the system, continue to stir and react for 12 hours, and then centrifuge (rotating speed is 5000-8000 rpm, time is 2-20min) to obtain the upper layer of AlH 3 ·N(Et) 3 Serum.

[0037] 2. AlH 3 ·N(Et) 3 Put the solution into a three-necked flask with a constant pressure separatory funnel, put 5mL of RDX saturated acetone solution into the constant pressure separatory funnel, move it into the Schulent line, vacuumize the system, and circulate nitrogen three times to maintain nitrogen atmosphere. AlH 3 ·N(Et) 3 The solution was heated to 110°C.

[0038] 3. Measure 0...

Embodiment 2

[0041] A preparation method of nano Al / RDX core-shell structure energetic composite particles, the steps are as follows:

[0042] 1. At 30°C, add 0.01mol anhydrous AlCl 3 Dispersed in 100ml of ether solution, under vigorous stirring, 0.04mol of N(Et) 3 Add to AlCl at a rate of 1-2 drops / sec 3 in ether solution. AlCl to be solid 3 After gradually dissolving, slowly add 0.03mol of LiAlH 4 Add it into the system, continue to stir and react for 16 hours, and then centrifuge (rotating speed is 5000-8000 rpm, time is 8-15min) to obtain the upper layer of AlH 3 ·N(Et) 3 Serum.

[0043] 2. AlH 3 ·N(Et) 3 Put the solution into a three-neck flask with a constant pressure separating funnel, put 10ml of RDX saturated DMF solution into the constant pressure separating funnel, and connect it to the Schrente line.

[0044] 3. Under the protection of argon atmosphere and stirring, measure 0.02mL of titanium tetrachloride and quickly inject it into the three-necked flask with a syring...

Embodiment 3

[0047] A preparation method of nano Al / RDX core-shell structure energetic composite particles, the steps are as follows:

[0048] 1. At room temperature, add 0.01mol anhydrous AlCl 3 Dispersed in 80ml of ether solution, 0.04mol of N(C 4 h 8 )CH 3 Add to AlCl at a rate of 1-2 drops / sec 3 in ether solution. Solid state AlCl 3 After dissolving, slowly add 0.03mol LiAlH 4 Add it into the system, continue to stir and react for 24 hours, and then centrifuge (rotating speed is 5000-8000 rpm, time is 8-15min) to obtain the upper layer of AlH 3 ·N(C 4 h 8 )CH 3 Serum.

[0049] 2. AlH 3 ·N(C 4 h 8 )CH 3 Put the solution into a three-necked flask with a constant pressure separating funnel, put 10mL of RDX saturated cyclohexane solution into the constant pressure separating funnel, and connect it to the Schlenk line.

[0050] 3. Under nitrogen atmosphere, under stirring, quickly inject 0.05ml of titanium tetrachloride into the three-neck flask with a syringe, the system tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com