Feeding method and feeding equipment for titanium dioxide calcination rotary kiln

A feeding method and technology of rotary kiln, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of insufficient utilization of high temperature flue gas heat, high energy consumption in calcination process, unstable product quality, etc. The effect of improving utilization rate, reducing calcination energy consumption, and shortening calcination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

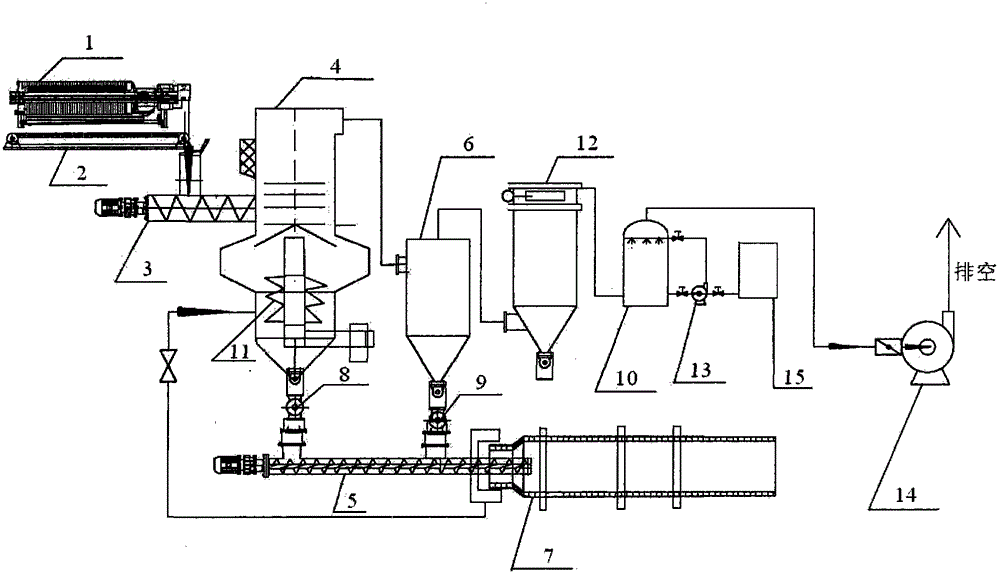

[0026] The titanium dioxide calcining rotary kiln feeding method includes the following steps:

[0027] 1. Conveying step: the metatitanic acid material separated and pressed to a moisture content of 50-55% by the diaphragm filter press (1) is fed into the flash evaporation through the belt conveyor (2) and the first screw conveyor (3). Drying host (4);

[0028] 2. Flash drying step: the metatitanic acid material entering the flash drying main unit (4) is in contact with the high-temperature flue gas from the kiln tail, and the high-temperature flue gas temperature is 350-450 ℃. , the material is crushed, dispersed and dried, and part of the material falling into the bottom is guided by the first star discharge valve (8) into the second screw conveyor (5) and then into the rotary kiln (7);

[0029] 3. Recovery step: The dried powdery and small granular materials enter the cyclone dust collector (6) tangentially from the top of the flash drying main unit with the swirling airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com