Collagen-inorganic metal salt flocculating agent and preparation method thereof

A technology of inorganic metal salt and collagen, which is applied in the field of protein flocculant and its preparation, can solve the problems of high cost and large dosage, and achieve the effect of low cost, low toxicity and increased molecular size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First add 100 parts of hydrolyzed collagen with a relative molecular weight of 2000-5000Da to 600 parts of water and stir to dissolve, then dissolve 1 part of formaldehyde in water, heat at 30°C for 0.5h, add collagen aqueous solution, and stir at 30°C React for 4 hours, and obtain cross-linked collagen after cooling; add 150 parts of aluminum sulfate to the obtained 100 parts of cross-linked collagen, adjust the pH to 2.5, and stir and react at 50°C for 2 hours, and obtain liquid form after cooling Collagen flocculant.

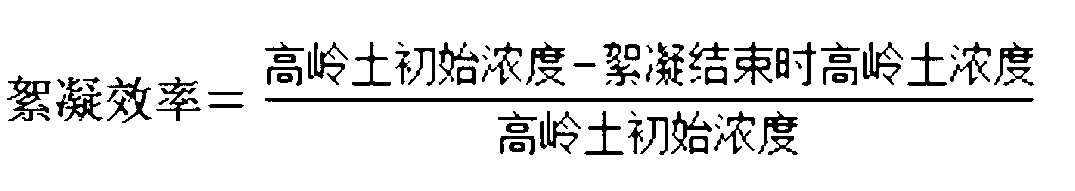

[0030] The molecular weight distribution of the cross-linked collagen obtained in this example is 8000-35000 Da, and the flocculation efficiency of the obtained flocculant is 0.8572.

Embodiment 2

[0032] First, add 100 parts of hydrolyzed collagen with a relative molecular weight of 6000-8000Da to 700 parts of water and stir to dissolve, then dissolve 15 parts of glutaraldehyde in water, and heat it at 50°C for 1.5h, then add it to the aqueous collagen solution, at 50 Stir and react at ℃ for 4 hours, and obtain cross-linked collagen after cooling; add 100 parts of ferric sulfate to the obtained 100 parts of cross-linked collagen, adjust the pH to 3.0, and stir and react at 30 °C for 4 hours, and obtain liquid after cooling Collagen flocculant.

[0033] The molecular weight distribution of the cross-linked collagen obtained in this example is 12000-68000 Da, and the flocculation efficiency of the obtained flocculant is 0.9536.

Embodiment 3

[0035]First, add 100 parts of hydrolyzed collagen with a relative molecular weight of 3000-6000Da extracted from chromium-containing waste skin slag by the method disclosed in Patent Application No. 201210536906.6 into 500 parts of water and stir to dissolve, then dissolve 3 parts of glutaraldehyde in water , and heated at 30°C for 1.0h, added to the collagen aqueous solution, stirred and reacted at 30°C for 5h, and obtained cross-linked collagen after cooling; adding 50 parts of aluminum sulfate to the obtained 100 parts of cross-linked collagen, The pH was adjusted to 3.0, and stirred and reacted at 30° C. for 3 hours, and a liquid collagen flocculant was obtained after cooling.

[0036] The molecular weight distribution of the cross-linked collagen obtained in this example is 10000-45000 Da, and the flocculation efficiency of the obtained flocculant is 0.8849.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com