N-salicylidene zinc glycinate compound and application thereof as PVC heat stabilizer

A technology based on zinc glycinate and salicinate, which is applied in the field of zinc-containing compounds to achieve the effects of easy availability of raw materials, improvement of initial colorability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] N - Preparation of zinc salicylidene glycinate compound:

[0021] Add 75 g of glycine, 500 mL of deionized water, and 40 g of NaOH into a 2L beaker, and stir to form a solution.

[0022] Salicylaldehyde ethanol solution (122 g of freshly distilled salicylaldehyde dissolved in 500 mL of ethanol) was dropped into the aqueous solution in the above 2L beaker, and stirred for 20 min. An aqueous solution of zinc acetate (184 g of zinc acetate dissolved in 500 mL of deionized water) was added into the above 2 L beaker, and kept stirring for 20 min. After standing overnight, crystals precipitated out. After suction filtration, washing with water, washing with alcohol, and drying, the target product was obtained. The filtrate is retained and can be used for the subsequent synthesis of the target product.

Embodiment 2

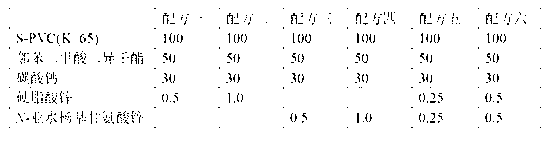

[0024] The composition of the test formulations is shown in Table 1 below. The data are in parts by weight based on 100 parts by weight of PVC resin.

[0025] Table 1

[0026]

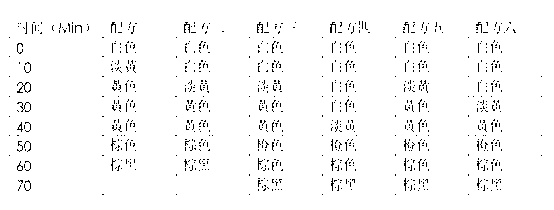

[0027] Put the above mixture on a two-roller plasticizing machine with a roller temperature of 160°C and a roller distance of 1 mm for 3 minutes. After taking the piece, cut it into a 2 cm × 2cm square test piece. According to the requirements of GB / T 7141-92 standard, put The PVC sheets are grouped and placed in the aging oven in order, and the oven aging test is carried out at 170±1°C. The test pieces are taken out every 10 minutes, and the changes in the color of the test pieces are observed and recorded. The time lasts until the test pieces appear black. , the results are shown in Table 2;

[0028] Table 2

[0029]

[0030] It can be seen from Table 2 that compared with the comparison formulas 1, 2 and 3, formulas 4, 5 and 6 have improved initial coloring and long-term stability to a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com