Electroluminescent material, preparation method for same, and luminescent device prepared from electroluminescent material

A technology for electroluminescent materials and light-emitting devices, applied in the directions of light-emitting materials, electro-solid devices, electrical components, etc., can solve the problems of high production cost, unsatisfactory light-emitting brightness decay life, complicated preparation, etc. Conducive to the effect of industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

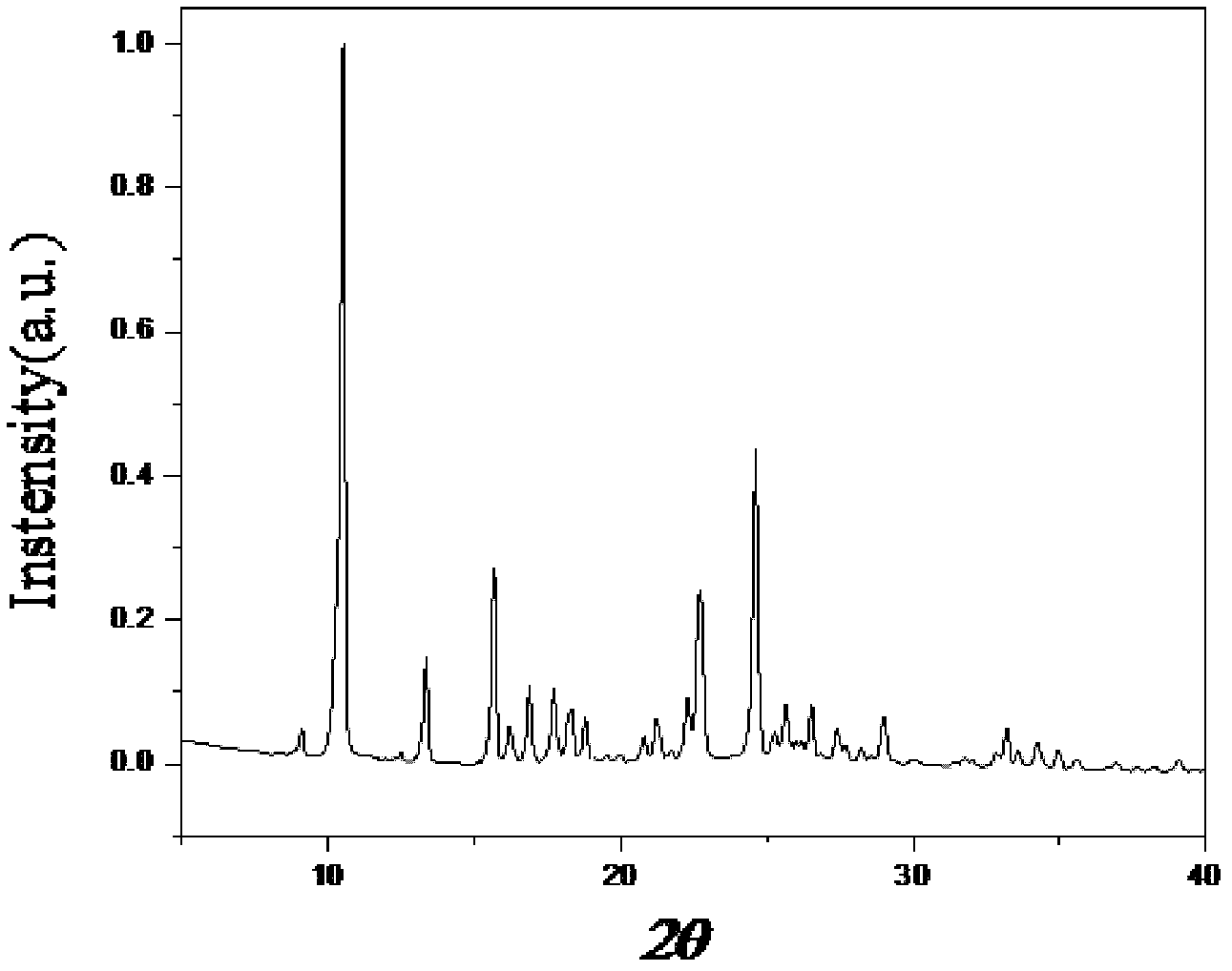

[0034] 10g aluminum trichloride is dissolved in 60ml deionized water to obtain aluminum trichloride solution, 40g 8-hydroxyquinoline is dissolved in 100ml ethanol to obtain the ethanol solution of 8-hydroxyquinoline, after these two kinds of solutions are mixed, in Concentrate to about 50ml at 70°C, then keep the temperature at 70°C, and slowly drop into saturated sodium chloride solution under stirring condition. Yellow-green 8-hydroxyquinoline aluminum gradually precipitated, and the precipitate was filtered after the reaction was complete. The crude product was washed 3 times with deionized water and 5 times with methanol, and then dried in vacuum at 70° C. to obtain the final product. The XRD pattern of this product is as follows figure 1 shown.

Embodiment 2

[0036]20g aluminum isopropoxide is dissolved in 100ml ethanol to obtain aluminum isopropoxide solution, 52g 8-hydroxyquinoline is dissolved in 100ml acetone to obtain the acetone solution of 8-hydroxyquinoline, after these two kinds of solutions are mixed, at 70 °C to about 50ml, then maintain the temperature at 70 °C, and slowly add a saturated solution of sodium sulfate dropwise under stirring conditions. Yellow-green 8-hydroxyquinoline aluminum gradually precipitated, and the precipitate was filtered after the reaction was complete. The crude product was washed 5 times with deionized water and 7 times with tetrahydrofuran, and then dried in vacuum at 70° C. to obtain the final product.

Embodiment 3

[0038] Dissolve 30g aluminum sulfate octadecahydrate in 60ml deionized water to obtain aluminum sulfate octadecahydrate solution, dissolve 49g 8-hydroxyquinoline in 100ml methanol to obtain a methanol solution of 8-hydroxyquinoline, after mixing these two solutions, Concentrate to about 50ml at 60°C, then keep the temperature at 60°C, and slowly drop into saturated sodium sulfate solution under stirring condition. Yellow-green 8-hydroxyquinoline aluminum gradually precipitated, and the precipitate was filtered after the reaction was complete. The crude product was washed 7 times with deionized water and 3 times with tetrahydrofuran, and then dried in vacuum at 70° C. to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com