New low-cost oxidation denitrating technology

A low-cost, new process technology, applied in the field of liquid-phase oxidation denitrification process, can solve the problem of high cost of denitrification process, achieve the effects of good absorption effect, easy industrialization implementation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

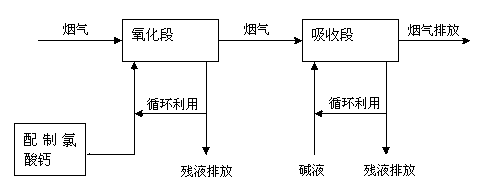

[0034] A new low-cost oxidation denitrification process, the specific steps are as follows:

[0035] A Prepare calcium chlorate solution

[0036] Using lime water and chlorine gas as raw materials, prepare an aqueous solution with a chlorate ion concentration of 50 g / L;

[0037] B Oxidation section

[0038] In the oxidation section, after diluting the prepared aqueous solution, it is sprayed into the oxidation tower from the upper part of the oxidation tower as an oxidant, and countercurrently contacts with the flue gas entering from the lower part, so that the nitrogen oxides in the flue gas are oxidized;

[0039] C absorption section

[0040] In the absorption section, lye is used as the absorbent to spray into the absorption tower from the upper part of the absorption tower to absorb the nitrogen oxides in the oxidized flue gas, generate corresponding nitrite and dissolve in water, so as to achieve the purpose of denitrification.

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, on this basis:

[0043] The chlorate ion concentration of described A step is 100g / L.

[0044] After the aqueous solution of described B step is diluted, chlorate ion concentration is 5g / L.

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, on this basis:

[0047] The chlorate ion concentration of described A step is 200g / L.

[0048] After the aqueous solution of described B step is diluted, chlorate ion concentration is 50g / L.

[0049] The lye in the C step is lime water with a mass concentration of 0.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com