Method for preparing carbon fiber conductive concrete with melting snow and ice function

A technology of conductive concrete and carbon fiber, which is applied in the field of concrete, can solve the problems of reduced concrete strength, small long diameter of graphite, and increased resistivity, and achieve the effects of reduced resistivity, enhanced conductivity, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

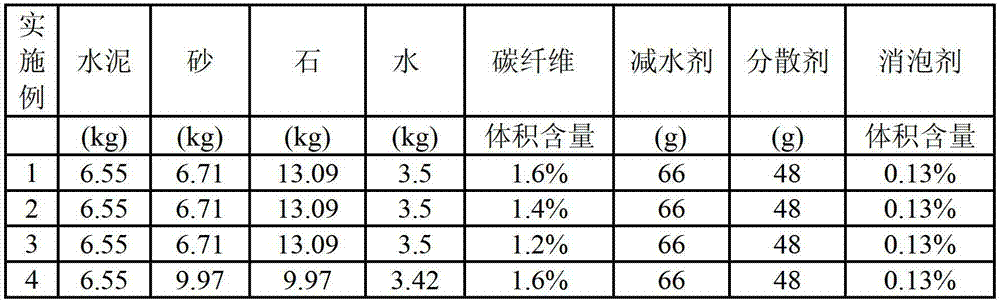

Embodiment 1~4

[0037] Pour the weighed cement and sand into the mixer and stir for 1 minute, then pour the mixed solution of water, water reducer, dispersant and defoamer into the mixer, stir for 1 minute, and spread the carbon fiber evenly Put it into the blender and stir for 1 minute, then pour the stones into the blender, and stop it after stirring for 3 minutes.

[0038] Pour the stirred mixture of Comparative Examples 1 and 2 and Examples 1 to 4 into a 160mm×130mm×40mm steel mold, and at the same time, embed stainless steel electrodes at both ends of the test piece, lead out the wires, vibrate on the vibrating table and move it into the standard Curing Indoor curing, demoulding after 1-2 days of curing. The resistance of the test piece was measured after 7 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com