Phenolic resin composition

A technology of phenolic resin and composition, applied in the field of phenolic resin composition, can solve problems such as poor toughness and insufficient heat resistance, and achieve the effects of high softening point, low free phenol and volatile matter, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

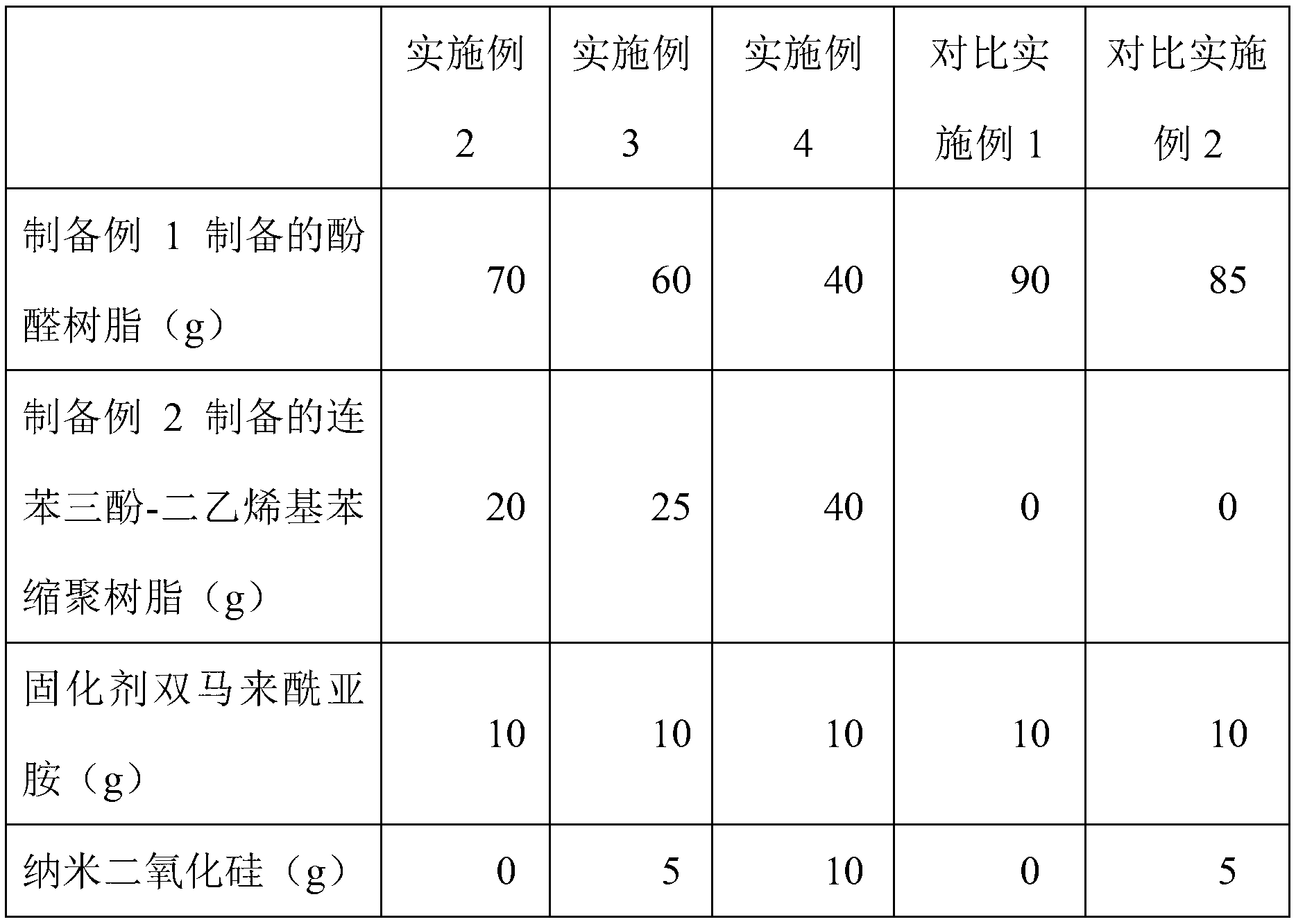

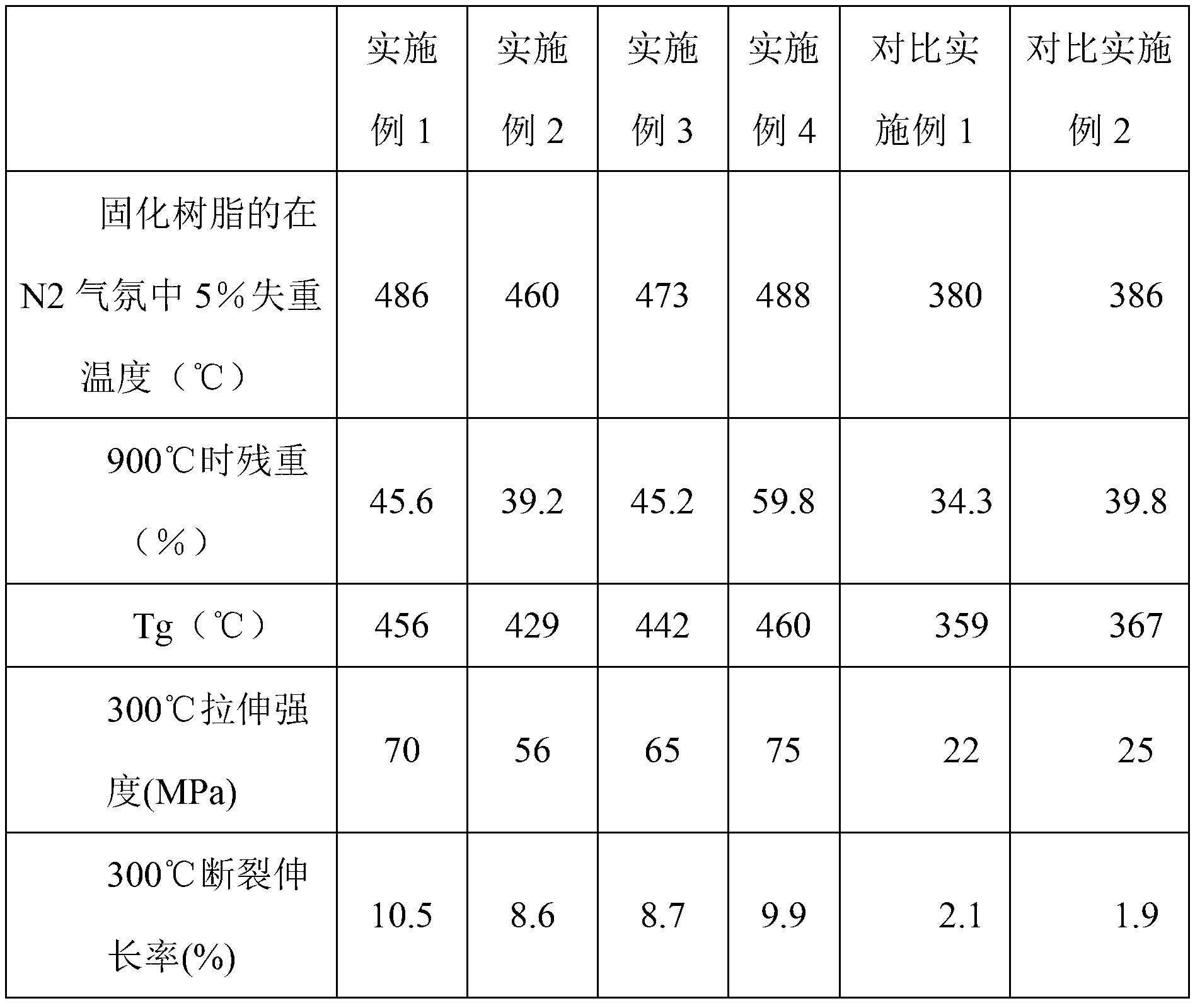

Examples

Embodiment

[0024] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art should understand that the following examples are only for illustrating the present invention, and should not be regarded as limiting the scope of the present invention. Those who do not indicate specific conditions in the embodiments, carry out according to conventional conditions.

preparation example

[0026] 1, the preparation of component a) phenolic resin of the present invention

[0027] Add phenol, formaldehyde, and oxalic acid into the reaction kettle according to the ratio of substances 1:0.5:0.02, heat and stir to 100°C, keep the temperature within this temperature range for 4 hours, and dephenolize by distillation under reduced pressure. The free phenol of the phenolic resin produced in this preparation example is 0.3wt%.

[0028] 2. Preparation of component b of the present invention) pyrogallol-divinylbenzene polycondensation resin

[0029] Under nitrogen protection, add pyrogallol 27.5g into a four-neck flask equipped with a stirrer, condenser, constant pressure dropping funnel and thermometer, add 200mL xylene, 0.75g oxalic acid, and drop 70.0mL1 after the raw materials are completely dissolved, 3-divinylbenzene, after reflux reaction at 80°C for 9 hours, heat up and distill water, solvent and unreacted raw materials until the resin becomes liquid, pour it out ...

Embodiment 1

[0031] Add 16.0g of pyrogallol, 200mL of 1,2-dichloroethane, 0.4g of p-toluenesulfonic acid, and After complete dissolution, add 20.0mL of 1,4-divinylbenzene dropwise, and react under reflux at 75°C for 10 hours, then heat up to distill water, solvent and unreacted raw materials until the resin becomes liquid to obtain pyrogallol-divinylbenzene polycondensation resin . Then add 40.0g of the phenolic resin prepared in Preparation Example 1 into the above-mentioned four-necked bottle, stir for 10 minutes, then raise the temperature to 130°C, add 10.0g of curing agent hexamethylenetetramine, continue stirring, and obtain the mixture after it is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com