Plasma atomic emission spectroscopy analysis method and plasma atomic emission spectroscopy analysis apparatus using gaseous sample injection

A technology of atomic emission spectroscopy and plasma, which is applied in the field of instrumentation, can solve the problems of instrument sensitivity and detection limit limitation, low sample atomization efficiency, etc., and achieve the effect of reducing instrument cost and improving measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

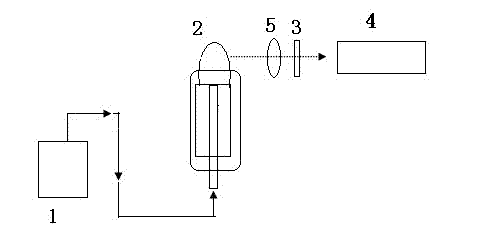

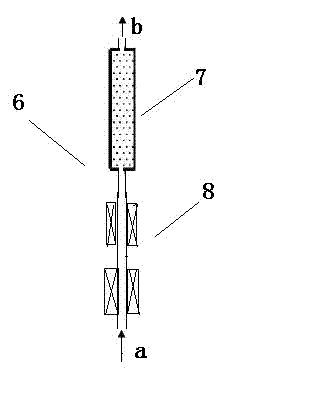

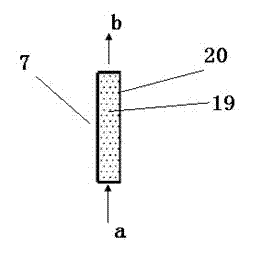

[0054] Such as Figure 1-4 For the sample injection shown, use a peristaltic pump to extract the sample solution to be determined and 1% dilute hydrochloric acid solution (remove the nitrogen in the reagent and experimental water in advance), the flow rate of the two solutions is 2 ml / min, and the two solutions The mixed reaction in the T-shaped glass tube with an inner diameter of 1.2 mm makes the inorganic carbon in the solution generate carbon dioxide, and the mixed liquid and carbon dioxide are pumped into the gas-liquid separator (element volatile separation device 1), and the mixed solution is separated along the The inner wall of the container flows down, and then flows through the glass frit sieve plate at the bottom, and the carrier gas (high-purity argon, flow rate 300 ml / min) is passed under the sieve plate to separate the carbon dioxide gas generated by the reaction and be carried by the carrier gas. To a semiconductor condensing tube (semiconductor refrigeration d...

Embodiment 2

[0056] Use an inductively coupled plasma 2 with a frequency of 40.68MHz as the light source, argon as the working gas, and mix the dilute inorganic acid (the reagents used and the dissolved inorganic carbon in the experimental water in advance) with the sample solution to be tested online or offline Reaction, the mixed solution containing carbon dioxide generated by the reaction is discharged into a gas-liquid separator 1, and the carbon dioxide in the mixed solution is loaded into the plasma by the carrier gas (high-purity argon with a flow rate of 300 ml / min) in the separator Ionizing luminescence, by using a filter 3 and lens 5 with a bandwidth of 247±5nm, the spectrum of carbon enters the photomultiplier tube of the detector 2, and after comparing with the standard solution containing carbon, the inorganic concentration in the sample solution to be tested is measured. The total amount of carbon is 56.78 mg / L. This result is in good agreement with non-dispersive infrared sp...

Embodiment 3

[0058] Use an argon with a frequency of 27.12MHz as the working gas inductively coupled plasma as the light source, and use 0.1M urea solution (to remove the dissolved nitrogen and carbon dioxide in the reagents and experimental water in advance) with the sample to be tested online or offline The solution is mixed and reacted, and the mixed solution containing the nitrogen gas generated by the reaction is discharged into a gas-liquid separator, and the nitrogen gas generated by the reaction in the mixed solution in the separator is loaded by the carrier gas (high-purity argon with a flow rate of 300 ml / min) Ionize and emit light in the plasma, use a filter and lens with a bandwidth of 174±10nm to make the spectrum of carbon enter the photomultiplier tube of the detector, and compare it with the standard solution containing nitrite to measure the sample to be tested The total amount of nitrite in the solution is 6.80 mg / L. This result is in good agreement with the colorless spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com