Cobalt hydroxide, method for producing same, cobalt oxide, and method for producing same

A technology of cobalt hydroxide and a manufacturing method, which is applied in the directions of cobalt oxide/cobalt hydroxide, electrical components, battery electrodes, etc., can solve problems such as affecting battery safety and increasing gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~4)

[0144]

[0145] Add 0.35L of initial sample liquid into a 2L reaction vessel, and heat to the reaction temperature shown in Table 1.

[0146] Next, while stirring the reaction solution (initial sample liquid) in the reaction vessel at the stirring speed described in Table 1, the pH of the reaction solution reached the pH described in Table 1. Add the cobalt aqueous solution and the alkaline aqueous solution dropwise at the indicated reaction temperature and dropping time to carry out the neutralization reaction.

[0147] After the neutralization reaction, the reaction liquid was cooled, and then, the product was filtered and washed with water, and then dried at 70° C. to obtain cobalt hydroxide.

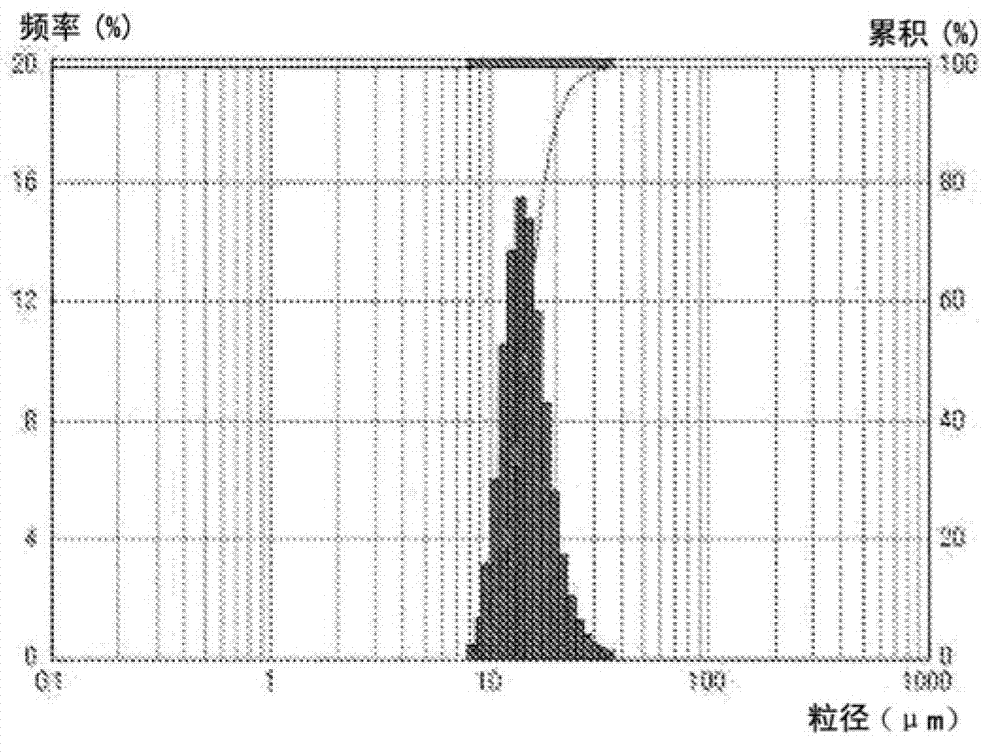

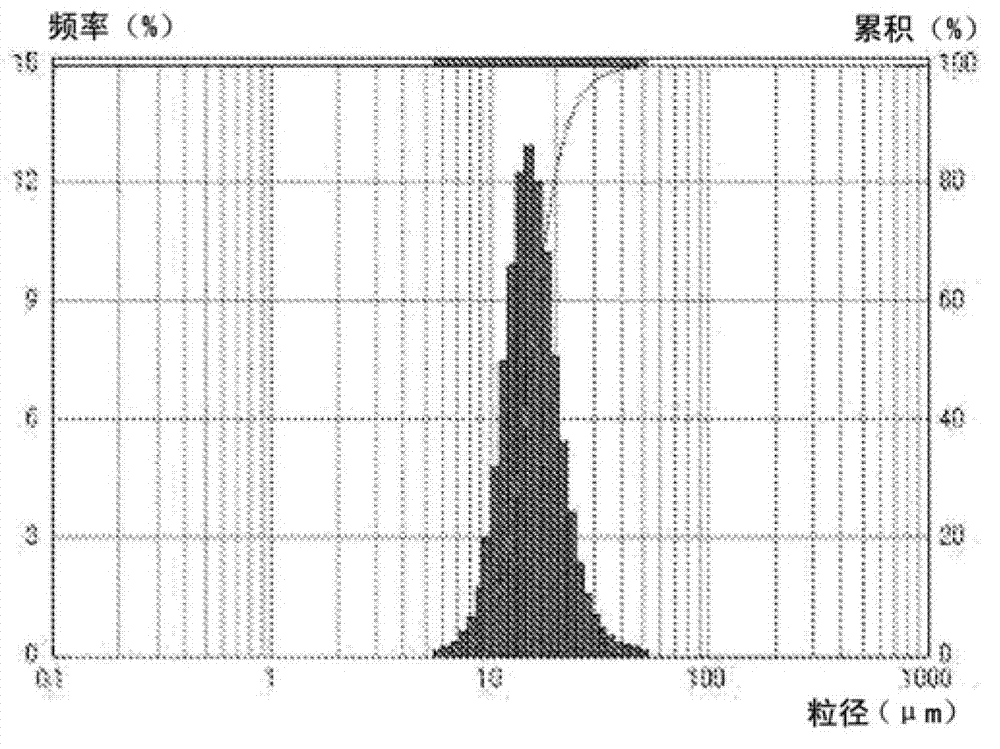

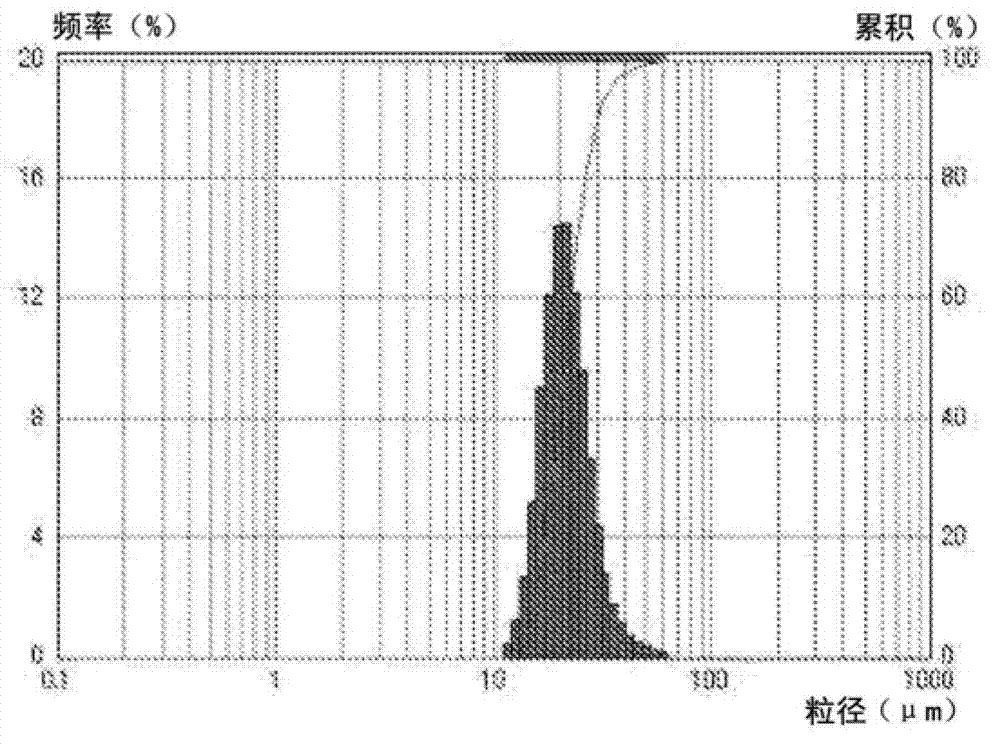

[0148] Table 2 shows the average particle diameter, compressive strength, pulverization characteristics, and tap density of the obtained secondary particles of cobalt hydroxide.

Embodiment 6)

[0150]

[0151] The reaction was carried out under the same conditions as in Examples 1 to 5 except that the reaction conditions shown in Table 1 were used to obtain cobalt hydroxide.

[0152] Table 2 shows the average particle diameter, compressive strength, pulverization characteristics, and tap density of the obtained secondary particles of cobalt hydroxide.

Embodiment 7)

[0154]

[0155] The cobalt hydroxide obtained in embodiment 3 was roasted in the atmosphere at 500° C. for 5 hours to obtain cobalt oxide (Co 3 o 4 ).

[0156] Table 2 shows the average particle diameter, compressive strength, pulverization characteristics, and tap density of the obtained secondary particles of cobalt oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com