Preparation method of boron nitride nanosheet-silver nanoparticle composite material

A technology of silver nanoparticles and composite materials, applied in the field of semiconductor material preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

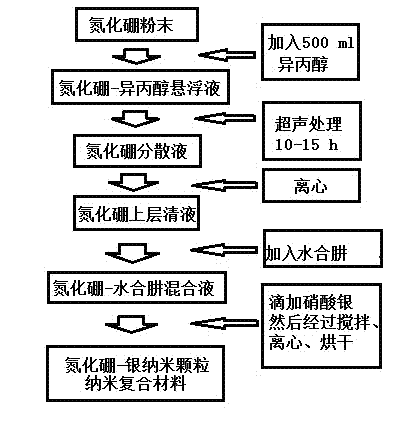

[0020] The process and steps for preparing boron nitride nanosheet-silver nanoparticle composites are as follows:

[0021] Weigh 500 mg of boron nitride powder (98%) and place it in a beaker, add 500 ml of isopropanol to prepare a suspension of boron nitride-isopropanol, and conduct discontinuous ultrasonic treatment with a low-power ultrasonic cleaner at room temperature for 10 ~15 h, and its optimal value is 12 h to obtain a boron nitride dispersion. After standing overnight, centrifuge the dispersion for 5-15 min, the optimum value is 10 min, and the rotation speed is 1000-3000 r / min, the optimum value is 2000 r / min; absorb the supernatant liquid on a clean glass Reserve in bottle.

[0022] In the supernatant obtained above, add 0.2 ml of hydrazine hydrate (N 2 h 4 ·H 2 O) solution, and constantly stirring, to obtain boron nitride-hydrazine hydrate mixed solution. According to a certain molar ratio, namely BN:N 2 h 4 ·H 2 O: AgNO 3 =1:25:5, slowly drop the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com