Method for microwave-assisted low-temperature rapid synthesis of ferrite ultrafine powder

A microwave-assisted synthesis method technology, which is applied in the field of microwave-assisted low-temperature rapid synthesis of ferrite micropowder, can solve the problems of unfavorable large-scale industrial production, long synthesis cycle, and many process steps, and achieve shortened production cycle, uniform components, and The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to Ni 0.5 Zn 0.5 Fe 2 o 4 For the stoichiometric ratio of ferrite, respectively weigh and analyze pure metal oxides NiO3.479g, ZnO3.423g and Fe 2 o 3 13.433g, put it into a stainless steel ball mill tank, use absolute ethanol as solvent, wet ball mill for 5 hours, the ratio of ball to material is 6:1, the slurry obtained by ball mill is dried and passed through a 100-mesh sieve to obtain the mixture. Put the mixture into an alumina ceramic crucible, cover it with a SiC auxiliary heating sheet, then place it in a microwave sintering furnace to raise the temperature to 680°C at a heating rate of 20°C / min, then keep it warm for 30min, the microwave frequency is 2.45GHz, and it is ready after cooling Ferrite powder.

Embodiment 2

[0020] This embodiment is a comparative experiment of embodiment 1.

[0021] Weigh the analytically pure metal oxides NiO, ZnO and Fe respectively 2 o 3 3.479, 3.423 and 13.433g each. Put the raw materials into a stainless steel ball mill tank, use absolute ethanol as a solvent, and perform wet ball milling for 5 hours with a ball-to-material ratio of 6:1. The slurry obtained from the ball mill is dried and passed through a 100-mesh sieve to obtain a mixture. Put the ball mill mixture into an alumina ceramic crucible, then place it in a box-type furnace sintering furnace, raise the temperature to 900°C at a heating rate of 10°C / min, keep it for 120min, and obtain ferrite powder after cooling.

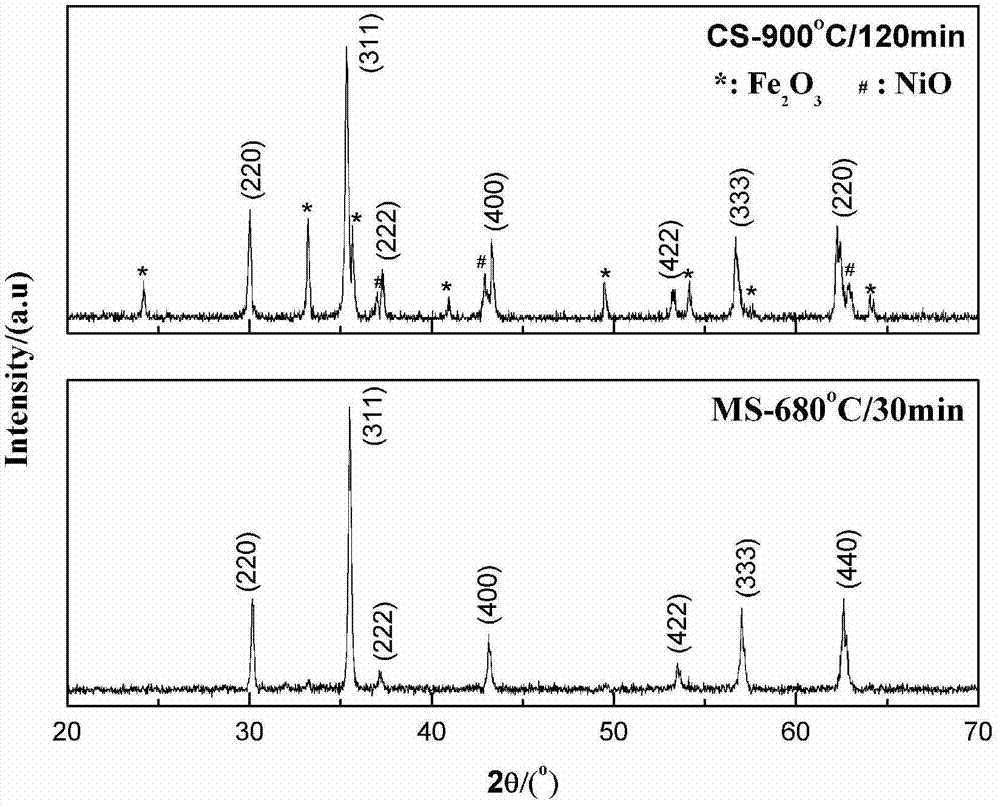

[0022] figure 1 Ni was synthesized by conventional solid-state reaction and microwave-assisted solid-phase synthesis. 0.5 Zn 0.5 Fe 2 o 4 XRD pattern of ferrite powder. From figure 1 It can be seen that Example 1 adopts microwave-assisted low-temperature rapid synthesis to obta...

Embodiment 3

[0026] According to Ni 0.7 Zn 0.3 Fe 2 o 4 For the stoichiometric ratio of ferrite, respectively weigh and analyze pure metal oxides NiO4.871g, ZnO0.104g and Fe 2 o 3 13.51g, put into a stainless steel ball mill jar, use absolute ethanol as solvent, wet ball mill for 5 hours, the ball-to-material ratio is 6:1, the slurry obtained by the ball mill is dried and passed through a 100-mesh sieve to obtain the mixture. Put the mixture into an alumina ceramic crucible, cover it with a SiC auxiliary heating sheet, then place it in a microwave sintering furnace to raise the temperature to 950°C at a heating rate of 30°C / min, then keep it warm for 20min, the microwave frequency is 2.45GHz, and it is ready after cooling Ferrite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com