Domestication method for high temperature-resistant ethanol-tolerant aroma-producing yeast

An aroma-producing yeast and ethanol-resistant technology, which is applied in the field of bioengineering, can solve the problems that Zhilan-flavored liquor is not suitable, yeast cannot withstand high temperature and ethanol, etc., and achieve the effects of fast operation, high temperature resistance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

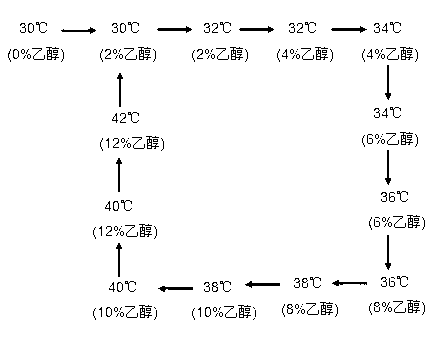

Image

Examples

Embodiment 1

[0029] (1) Aroma yeast koji was purchased from Shandong Liangshan Liangyou Bioengineering Co., Ltd., 2 g of dry koji was placed in a conical flask filled with 100 mL of sterile water and glass beads, shaken at 200 r / min for 30 min, and then tested Gradient dilution, take l0 -5 、10 -6 、10 -7 200 μL of diluted samples were evenly spread on the plate of YPD solid medium, and each sample was spread in parallel to 4 blocks. After the colony grows, select a single colony with typical yeast colony characteristics and further separate it by streaking 2 to 3 times. After microscopic examination, it is pure and transfer it to the slant of YPD solid medium, and store it at low temperature for later use.

[0030] Take the preserved pure yeast strain, culture it with wort medium at 30°C for 7 days to obtain a fermentation liquid, take the national standard GB / T 10345-2007 as the standard, smell the aroma and measure the alcohol content and total ester of the fermentation liquid, the yea...

Embodiment 2

[0050] The aroma-producing yeast koji was purchased from Xujia Koji Factory in Liangshan, Shandong. The difference between this example and Example 1 is that the immobilized aroma-producing yeast was subjected to high-temperature-resistant and ethanol-resistant cyclic gradient acclimation parameters in the ethanol acclimation medium:

[0051] Pre-cultivation: Place the immobilized Aroma yeast in YPD liquid medium (ie 0% ethanol), culture at 30°C for 42 hours, and then follow the steps below:

[0052] 1. Under sterile conditions, transfer the pre-cultured and immobilized aromatized yeast to the 3% ethanol acclimation medium (that is, the ethanol content is 2%), and cultivate it at 30°C for 42 hours:

[0053] 2. Transfer the immobilized Aroma yeast to 3% ethanol acclimation medium, and culture at 33°C for 42 hours;

[0054] 3. Transfer the immobilized Aroma yeast to 6% ethanol acclimation medium, and culture at 33°C for 42 hours;

[0055] 4. Transfer the immobilized aromatized ...

Embodiment 3

[0063] The aromatic yeast koji was purchased from Jinan Jiuyi Bioengineering Co., Ltd., and the method was the same as in Example 1. Finally, the aroma-producing yeast with high temperature and ethanol resistance was obtained: the temperature range of resistance was 36°C-40°C, and the concentration range of ethanol resistance was 5%-9%; and the total ester content and smell results remained stable with those before domestication.

[0064] The scope given by the claims of the present invention can be implemented, and the results are similar to those of Embodiments 1-3, which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com