Preparation method of baking syrup

A technology for syrup and baking, applied in the field of preparation of baking syrup, can solve the problems of low reducing sugar content and limited development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

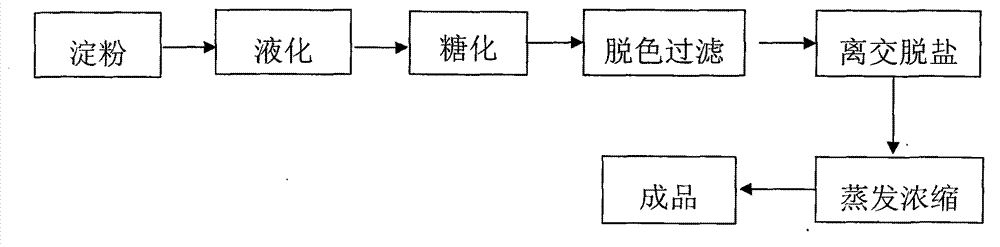

Image

Examples

Embodiment 1

[0016] Take the liquefied liquid with a DE value of 10-15%, put it into the saccharification tank, adjust the pH to 5.5, and the temperature is 60°C, add fungal enzymes, react for 7 hours, then add compound saccharification enzymes, and react for 24 hours. Sampling and detection by high performance liquid chromatography showed that the content of each component was 20.6% glucose, 18.3% maltose, 14.5% maltotriose, 43.2% tetrasaccharide and above, and DE value 42.8%.

[0017] Add 1% (mass ratio of powdered activated carbon to maltotriose on a dry basis) powdered activated carbon to the saccharification solution with qualified components and deactivated enzymes, stir evenly, keep for 30 minutes for decolorization, and then use a plate and frame filter press to filter the activated carbon. The filtered filtrate is subjected to ion exchange desalination.

[0018] The positive column of strong acid cation resin and the negative column of weak base anion resin respectively are treate...

Embodiment 2

[0021] Take the liquefied liquid with a DE value of 10-15%, put it into the saccharification tank, adjust the pH to 5.8, and the temperature is 55°C, add fungal enzymes, react for 12 hours, then add compound saccharification enzymes, and react for 24 hours. Sampling and detection by high performance liquid chromatography showed that the content of each component was 18.9% glucose, 19.6% maltose, 15.4% maltotriose, 44.7% tetrasaccharide and above, and the DE value was 42%.

[0022] Add 1% (mass ratio of powdered activated carbon to maltotriose on a dry basis) powdered activated carbon to the saccharification solution with qualified components and deactivated enzymes, stir evenly, keep for 30 minutes for decolorization, and then use a plate and frame filter press to filter the activated carbon. The filtered filtrate is subjected to ion exchange desalination.

[0023] The positive column of strong acid cation resin and the negative column of weak base anion resin respectively are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com