Method for analyzing and determining arsenic form in liquid food seasoning

A technology for liquid food and arsenic forms, which is applied in the field of analysis and determination of arsenic forms in liquid food seasonings, and compound analysis and determination. It can shorten the measurement cycle, save the cost of pretreatment, and improve the sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

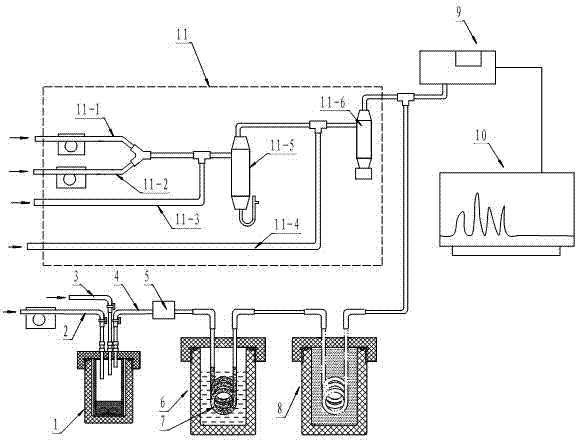

[0033] Example 1: The tested liquid food seasoning sample is No. 1 soy sauce. still refer to figure 1 , the m / v concentration 3%KBH 4 (0.3% KOH) and 20% HCl (v / v) are passed into the acid solution pipeline 11-1 and the alkali solution pipeline 11-2 of the hydrogen generator 11 respectively, and the two solutions are mixed at the tee to undergo hydrogenation reaction , producing a large amount of gaseous hydrogen and waste liquid. The generated hydrogen is brought into the primary gas-liquid separator 11-5 along with the argon in the carrier gas pipeline 11-3, and the gas-liquid can be separated to the maximum extent; the gaseous hydrogen is brought into the secondary gas-liquid separator along with the argon 11-6, the gas entering the secondary gas-liquid separator, under the action of argon in the auxiliary gas pipeline 11-4, smoothly enters the atomizer of the atomic fluorescence spectrometer 9 for combustion. The above-mentioned argon gas has a purity of 99.99% and a flo...

Embodiment 2

[0034] Embodiment 2: The tested liquid food seasoning sample is No. 2 soy sauce. still refer to figure 1 , the m / v concentration 3%KBH 4 (0.3% KOH) and 20% HCl (v / v) are passed into the acid solution pipeline 11-1 and the alkali solution pipeline 11-2 of the hydrogen generator 11 respectively, and the two solutions are mixed at the tee to undergo hydrogenation reaction , producing a large amount of gaseous hydrogen and waste liquid. The generated hydrogen is brought into the primary gas-liquid separator 11-5 along with the argon in the carrier gas pipeline 11-3, and the gas-liquid can be separated to the maximum extent; the gaseous hydrogen is brought into the secondary gas-liquid separator along with the argon 11-6, the gas entering the secondary gas-liquid separator, under the action of argon in the auxiliary gas pipeline 11-4, smoothly enters the atomizer of the atomic fluorescence spectrometer 9 for combustion. The above-mentioned argon gas has a purity of 99.99% and a ...

Embodiment 3

[0035] Embodiment 3: The tested liquid food seasoning sample is vinegar. still refer to figure 1 , the m / v concentration 3%KBH 4(0.3% KOH) and 20% HCl (v / v) are passed into the acid solution pipeline 11-1 and the alkali solution pipeline 11-2 of the hydrogen generator 11 respectively, and the two solutions are mixed at the tee to undergo hydrogenation reaction , producing a large amount of gaseous hydrogen and waste liquid. The generated hydrogen is brought into the primary gas-liquid separator 11-5 along with the argon in the carrier gas pipeline 11-3, and the gas-liquid can be separated to the maximum extent; the gaseous hydrogen is brought into the secondary gas-liquid separator along with the argon 11-6, the gas entering the secondary gas-liquid separator, under the action of argon in the auxiliary gas pipeline 11-4, smoothly enters the atomizer of the atomic fluorescence spectrometer 9 for combustion. The above-mentioned argon gas has a purity of 99.99% and a flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com