Metal glass optical grating and method and device for manufacturing same

A metal glass and grating technology, applied in the fields of condensed matter physics and material science, can solve the problems of low production efficiency, high production cost, increased preparation cycle, etc., and achieve the effects of high forming efficiency, small forming force and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

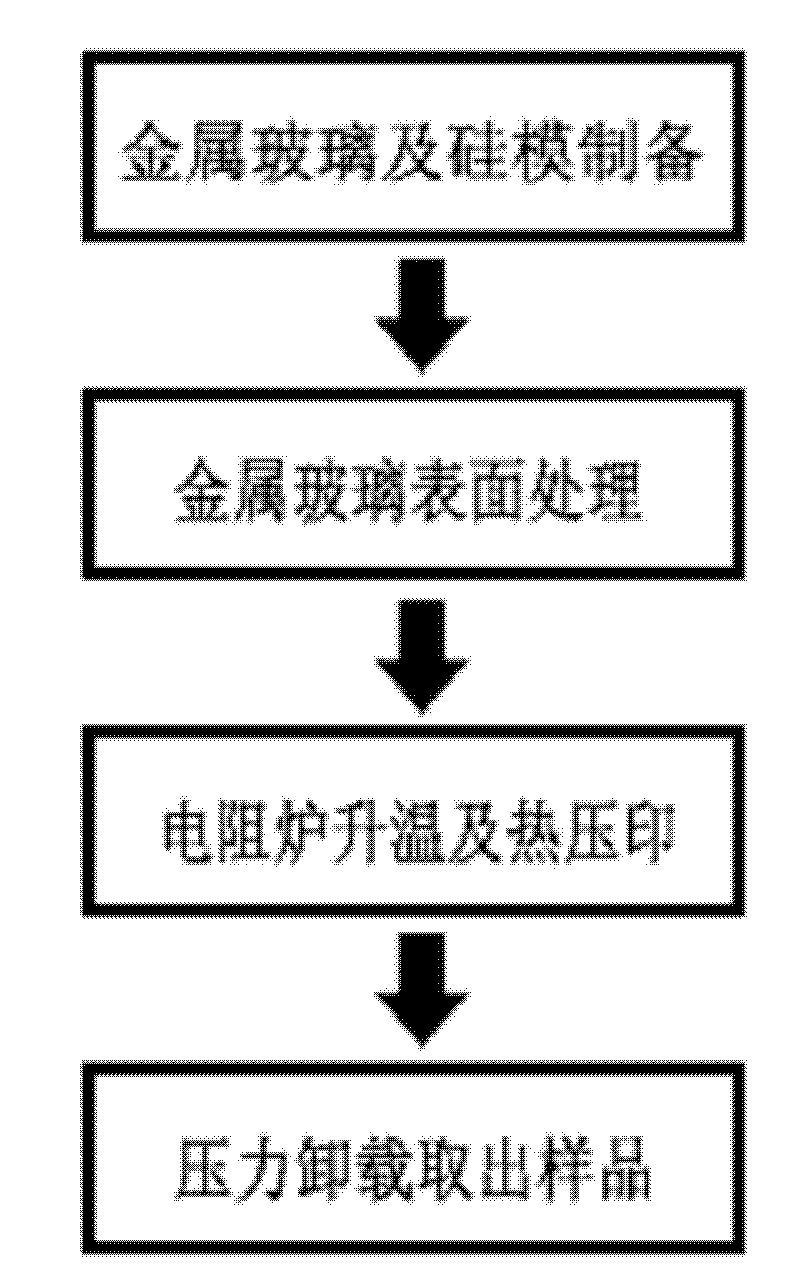

Method used

Image

Examples

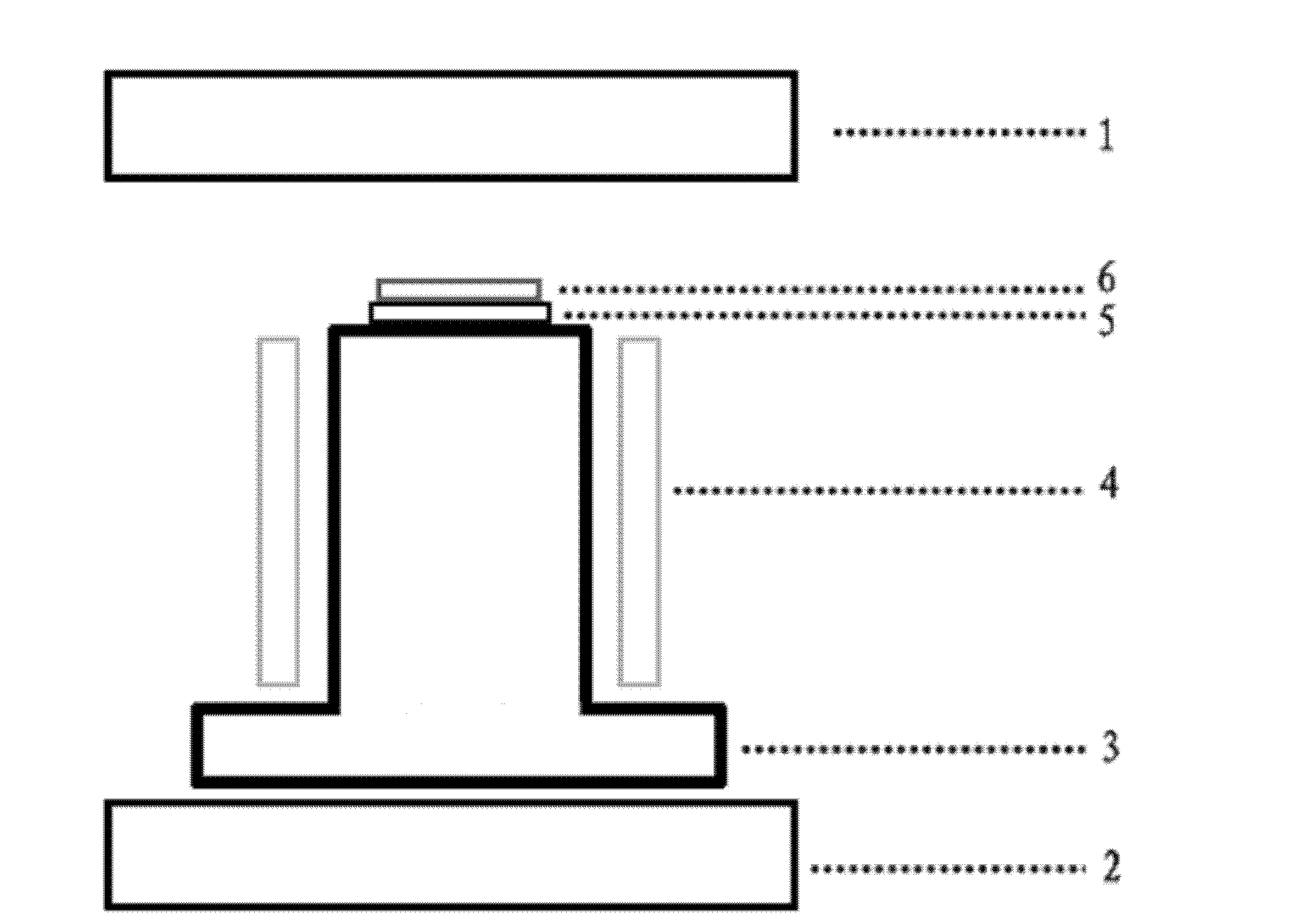

preparation example Construction

[0037] The method for preparing the metallic glass grating of the present invention may further include: after cooling the metallic glass thin plate having a grating structure, polishing with a diamond polishing paste with a particle size of 1.5 μm to remove slight oxidation on the surface of the metallic glass thin plate.

[0038] The metallic glass grating provided by the invention is based on metallic glass and has a periodic groove structure thereon. The metallic glass includes Pd-based, La-based, Ce-based, Zr-based, Mg-based, Au-based, Si-based, Sc-based, Dy-based, Er-based, Ho-based, Nd-based, Ni-based, NiNb-based, rare earth-based, Pr-based, Sm-based, Tb-based, Tm-based, Yb-based metallic glasses.

Embodiment 1

[0039] Example 1, Pd 40 Cu 30 P 20 Ni 10 Fabrication of Metallic Glass Gratings

[0040] Use the traditional copper mold water cooling method to convert the composition into Pd 40 Cu 30 P 20 Ni 10 (atomic percentage) the alloy melt is rapidly cooled to obtain a metallic glass sheet with a width of 8 mm, a thickness of 1 mm, and a length of 20 mm.

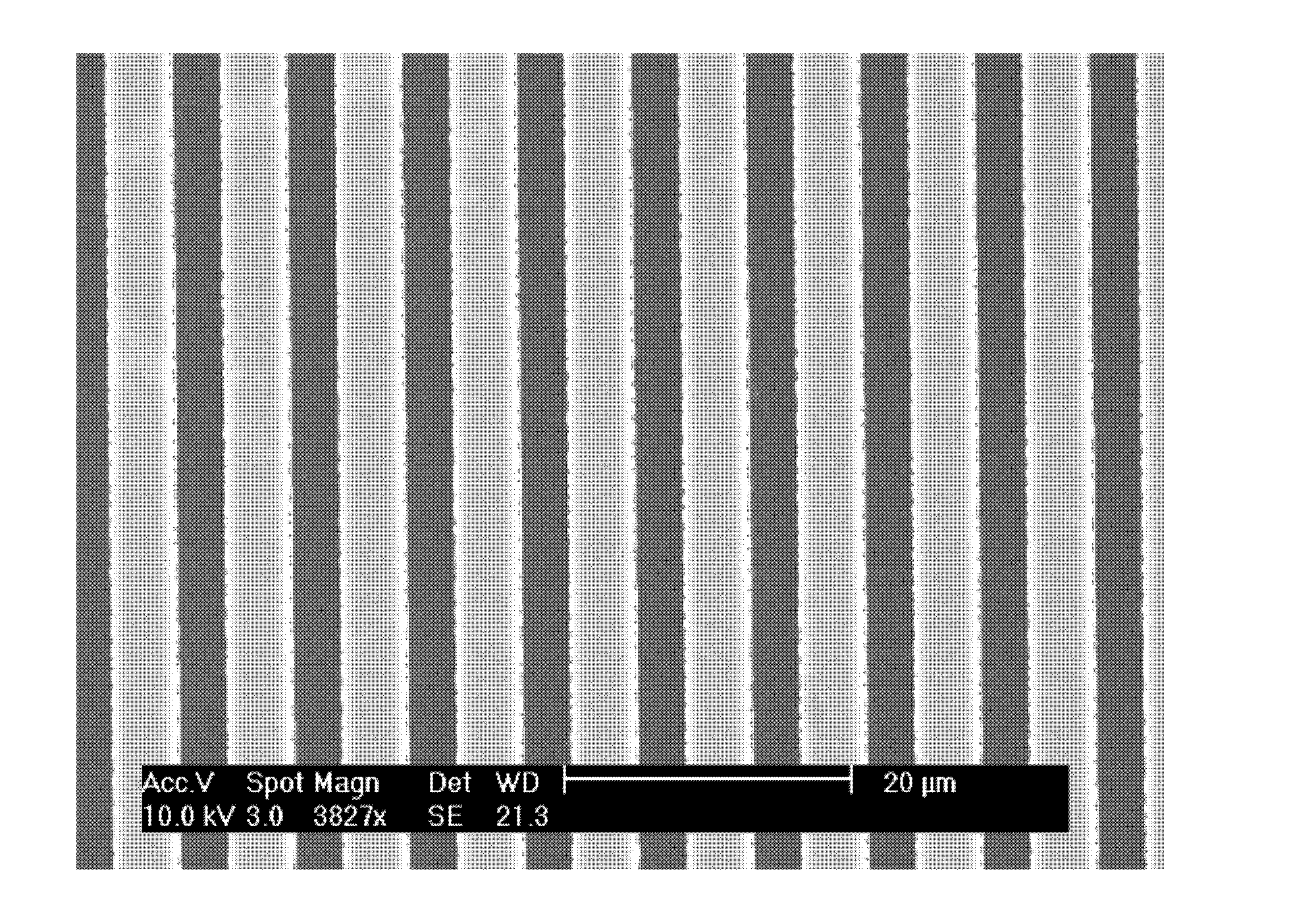

[0041] On the surface of the silicon mold with a size of 10 mm × 10 mm and a thickness of about 0.5 mm, a groove structure with a depth of 10 μm and a periodicity of 8 μm is etched by photolithography technology as the microstructure of the grating (such as image 3 shown) to be used as a mold for hot stamping of metallic glass.

[0042] The aforementioned Pd 40 Cu 30 P 20 Ni10 The thin plate of metallic glass is cut into a length of 5 mm with a cutting saw and stored for later use. The two sides of each metallic glass thin plate were polished with No. 400, No. 800, and No. 1200 sandpaper in sequence to obtain a flat sur...

Embodiment 2

[0045] Example 2, La 57.5 al 1.75 Cu 12.5 Ni 12.5 Fabrication of Metallic Glass Gratings

[0046] Same as the method in embodiment 1, when just preparing the thin plate of metallic glass, the composition of alloy melt is La 57.5 al 1.75 Cu 12.5 Ni 12.5 (atomic percent), the formed metallic glass sheet has a width of 8 mm, a thickness of 1 mm, and a length of 50 mm.

[0047] When preparing the silicon mold, the period and depth of the formed microstructure were 16 μm and 5 μm, respectively.

[0048] During hot embossing, the resistance furnace is heated to about 180 degrees Celsius at a heating rate of 10 degrees Celsius / min, and the temperature is kept constant; the compression rate of the compressor of the universal material testing machine is 0.3mm / min, and the pressure is maintained when the pressure increases to 15MPa 10s.

[0049] Made La 57.5 al 1.75 Cu 12.5 Ni 12.5 Metal glass grating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com