A temperature-stable heterogeneous multilayer dielectric ceramic capacitor and its preparation method

A ceramic capacitor, temperature-stable technology, applied in the direction of laminated capacitors, fixed capacitor dielectrics, fixed capacitor components, etc., can solve the problems of ceramic body delamination, warping, and mismatching sintering characteristics of heterogeneous components, etc., to achieve overcoming mismatch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

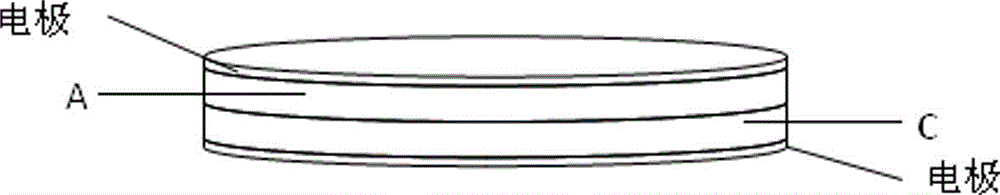

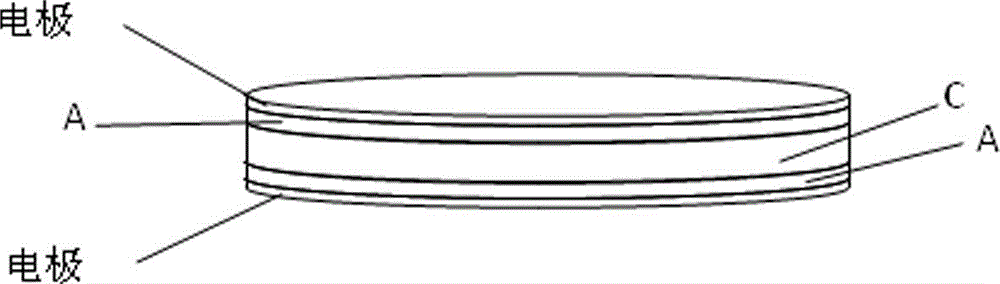

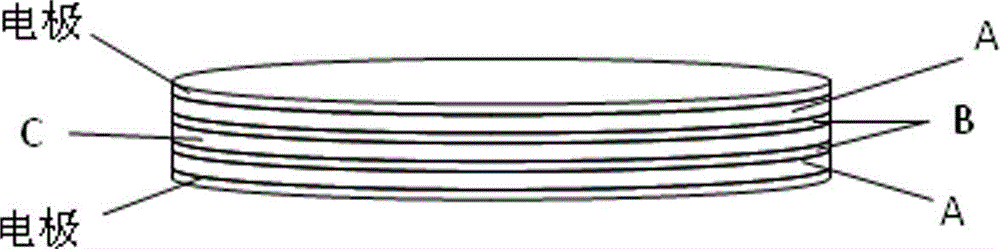

[0042] 1. According to the general formula Ba x Sr 1-x TiO 3 The ratio of the main materials of each layer of A, B, and C, as well as the doping raw materials and burning aids, are weighed in molar ratio, and TiO 2 The molar weight is 0.20mol for calculation and weighing;

[0043] Layer A is Ba 0.9 Sr 0.1 TiO 3 +0.15% La 2 o 3 +0.3%SiO2 2 ,

[0044] Layer B is Ba 0.77 Sr 0.33 TiO 3 +0.15%La 2 o 3 +0.15%Fe 2 o 3 +0.4% SiO 2 ,

[0045] C layer is Ba 0.55 Sr 0.45 TiO 3 +0.15%Fe 2 o 3 +0.8% SiO2 2 ,

[0046] The raw material powder is: BaCO 3 (purity 99.0%), SrCO 3 (purity 99.0%), TiO 2 (purity 98.0%), Fe 2 o 3 , (purity 99.9%) La 2 o 3 (purity 99.99%), SiO 2 (purity 99.0%) powder;

[0047] 2. Weigh the total weight of the powder according to the main materials of each layer of A, B, and C, add deionized water of the same quality, use zirconium balls with diameters of 15mm, 10mm, and 5mm, and a quantity ratio of 1:1:5 to carry out the following ste...

Embodiment 2

[0057] 1. According to the general formula Ba x Sr 1-x TiO 3 And the ratio of the main materials of each layer of A, B, and C, as well as the doping raw materials and burning aids, weighed in molar ratio, and take TiO 2 The molar weight is 0.20mol for calculation and weighing;

[0058] Layer A is Ba 0.92 Sr 0.08 TiO 3 +0.5% Ta 2 o 3 +0.1%Y 2 o 3 +1.2% SiO2 2 ,

[0059] Layer B is Ba 0.73 Sr 0.37 TiO 3 +0.15%Nb 2 o 5 +0.1% Fe 3 o 4 +0.8% SiO2 2 ,

[0060] C layer is Ba 0.55 Sr 0.45 TiO 3 +1.0% Fe 2 o 3 +1.5% SiO2 2 ,

[0061] The raw material powder is: BaCO 3 (purity 99.0%), SrCO 3 (purity 99.0%), TiO 2 (purity 98.0%), Fe 2 o 3 , (purity 99.9%) La 2 o 3 (purity 99.99%), SiO 2 (purity 99.0%) powder;

[0062] 2. Weigh the total weight of the powder according to the main materials of each layer of A, B, and C, add deionized water of the same quality, use zirconium balls with diameters of 15mm, 10mm, and 5mm, and a quantity ratio of 1:1:5 to carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com