Sodium-ion battery positive material and preparation method and application thereof

A technology of sodium ion battery and positive electrode material, which is applied to battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low theoretical specific capacity, achieve high capacity, simple and convenient synthesis, and improve conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

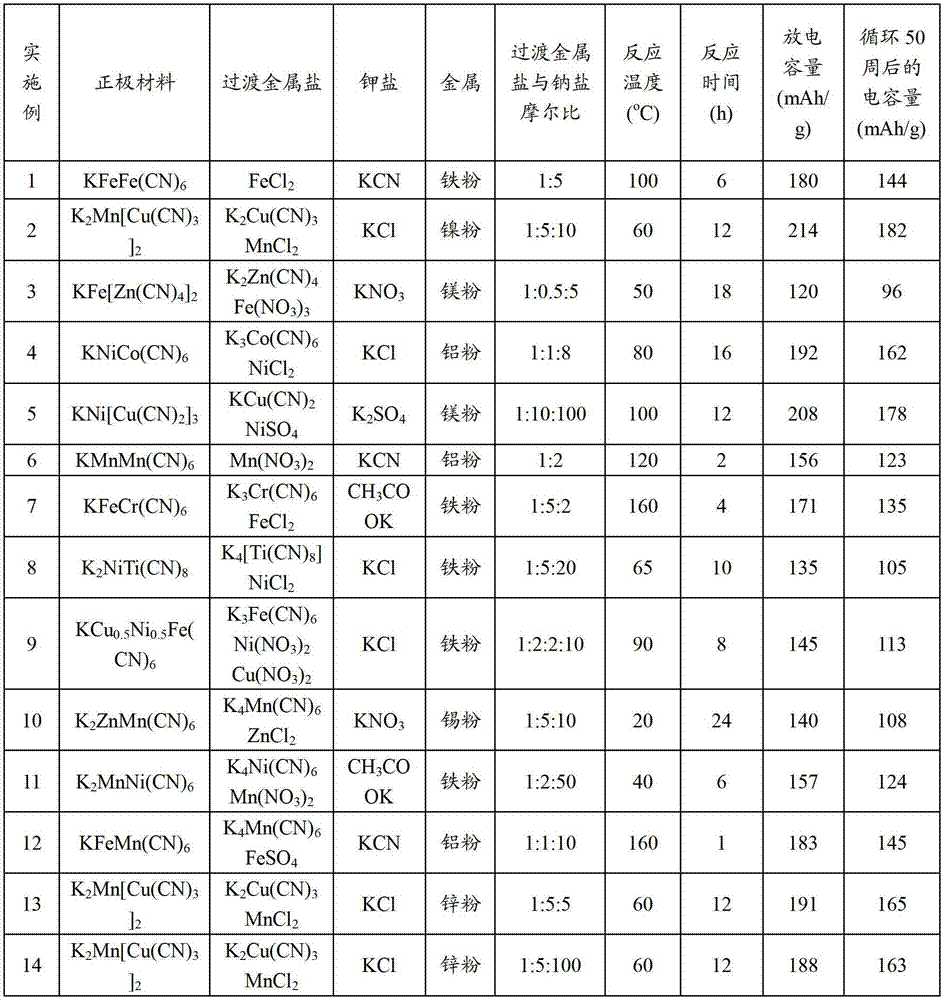

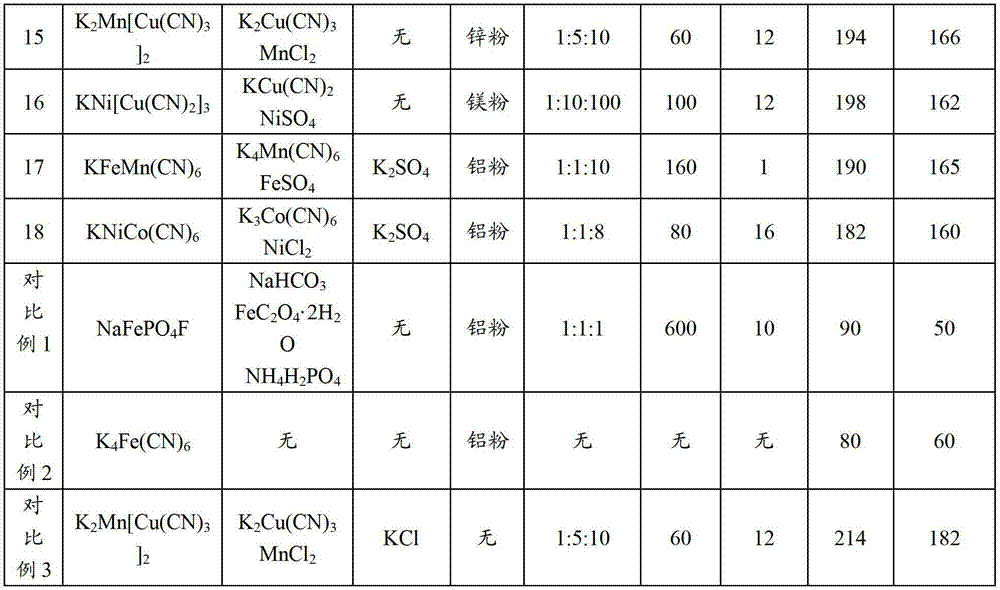

[0021] Example 1. Prussian blue compound / metal composite cathode material and its preparation and performance

[0022] By FeCl 2 : KCN:Iron powder=1:5:5 mole fraction, add water as a solvent, heat at 100℃ for 6h and then let stand for 2h. After the reaction is completed, it is separated and dried to obtain the Prussian blue compound / metal composite positive electrode material provided by the present invention.

[0023] The electrochemical analysis test is carried out on the Prussian blue compound / metal composite positive electrode material obtained by the invention, and the charge and discharge range is 2.0-4.2V. When charged and discharged at a current density of 20 mA / g, the capacity of the material can reach 140 mAh / g, and the capacity does not decay significantly after 50 cycles, which proves that the composite material obtained by the invention has high capacity and cycle performance. The composition of the obtained sodium ion cathode material and the test results in th...

Embodiment 2

[0024] Example 2. Prussian blue compound / metal composite cathode material and its preparation and performance

[0025] Put 0.01mol K 2 Cu(CN) 3 and 0.1mol KCl was dissolved in 100mL water to obtain a clear solution, and the solution was slowly dropped into 100mL0.05mol / L MnCl at 60°C 2 and 0.05mol / L nickel powder in a homogeneous mixed aqueous solution, stirred for 12h and then allowed to stand for 2h. After the reaction is completed, it is separated and dried to obtain the Prussian blue compound / metal composite positive electrode material provided by the present invention. The composition of the obtained sodium ion cathode material and the test results in the simulated battery are listed in Table 1.

Embodiment 3

[0026] Example 3. Prussian blue compound / metal composite cathode material and its preparation and performance

[0027] Put 0.01mol K 2 Zn(CN) 4 and 0.05mol KCl were dissolved in 100mL of water to obtain a clear solution, and the solution was slowly dropped into 100mL of 0.05mol / L Fe(NO) at 50°C. 3 ) 3 In the aqueous solution, stirred for 18h and then allowed to stand for 2h. After completion of the reaction, separation and drying were carried out to obtain Prussian blue compounds. It is then ball-milled with magnesium powder for 2 hours to obtain the Prussian blue compound / metal composite positive electrode material provided by the present invention. The composition of the obtained sodium ion cathode material and the test results in the simulated battery are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com