Production line for squeezing and spreading mungbean noodle, vermicelli, sheet jelly and wide vermicelli

A technology of extrusion coating and production line, which is used in the production line of powder belt, vermicelli, vermicelli, and vermicelli. Hygienic, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

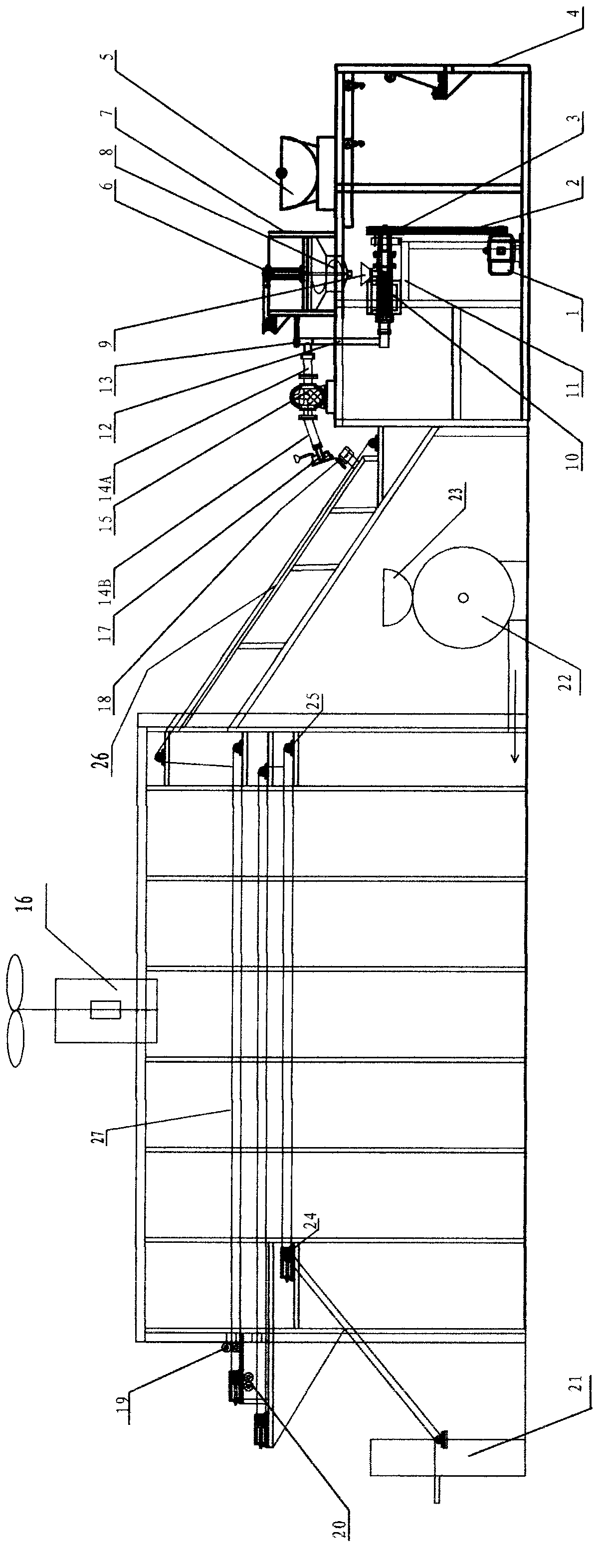

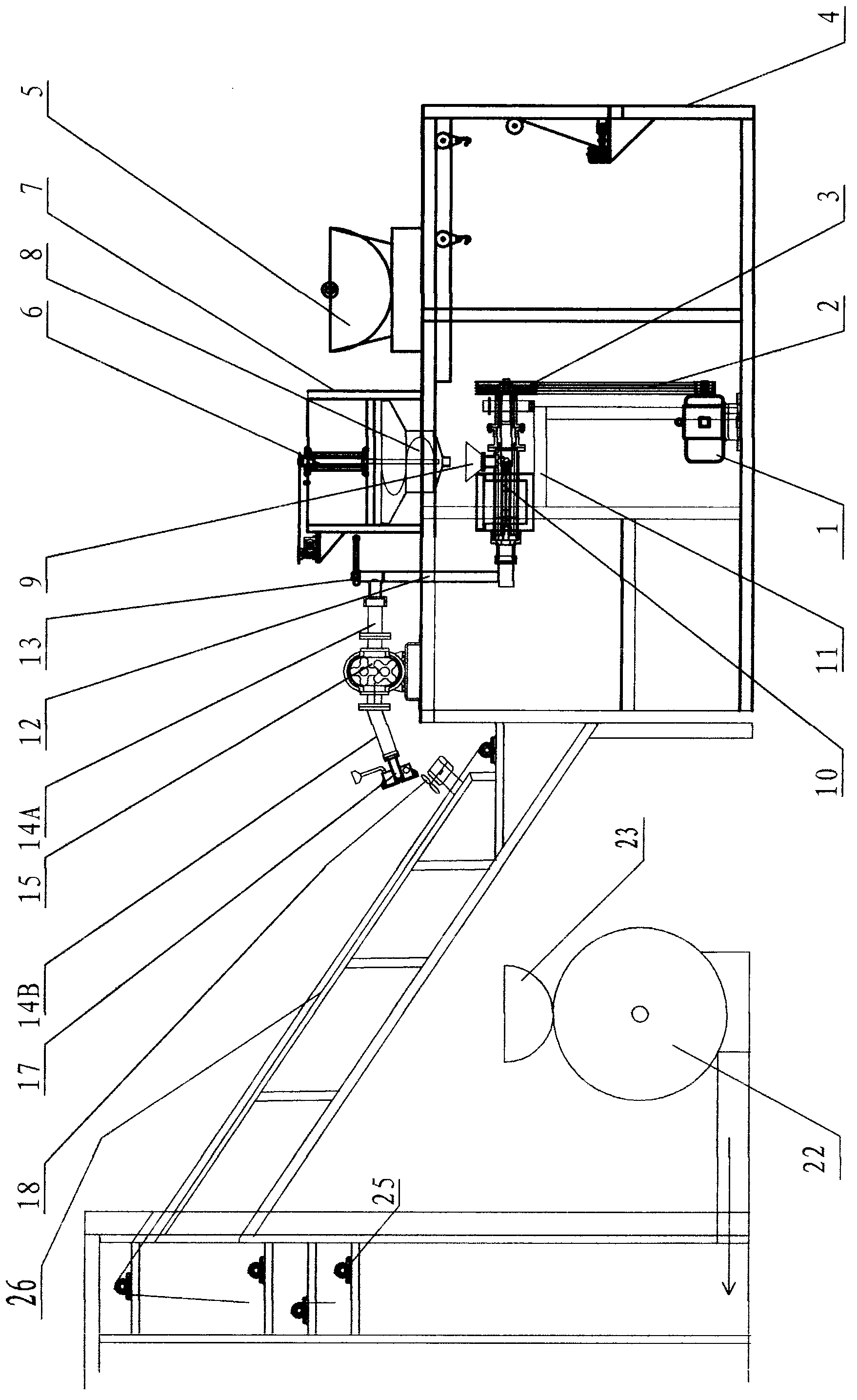

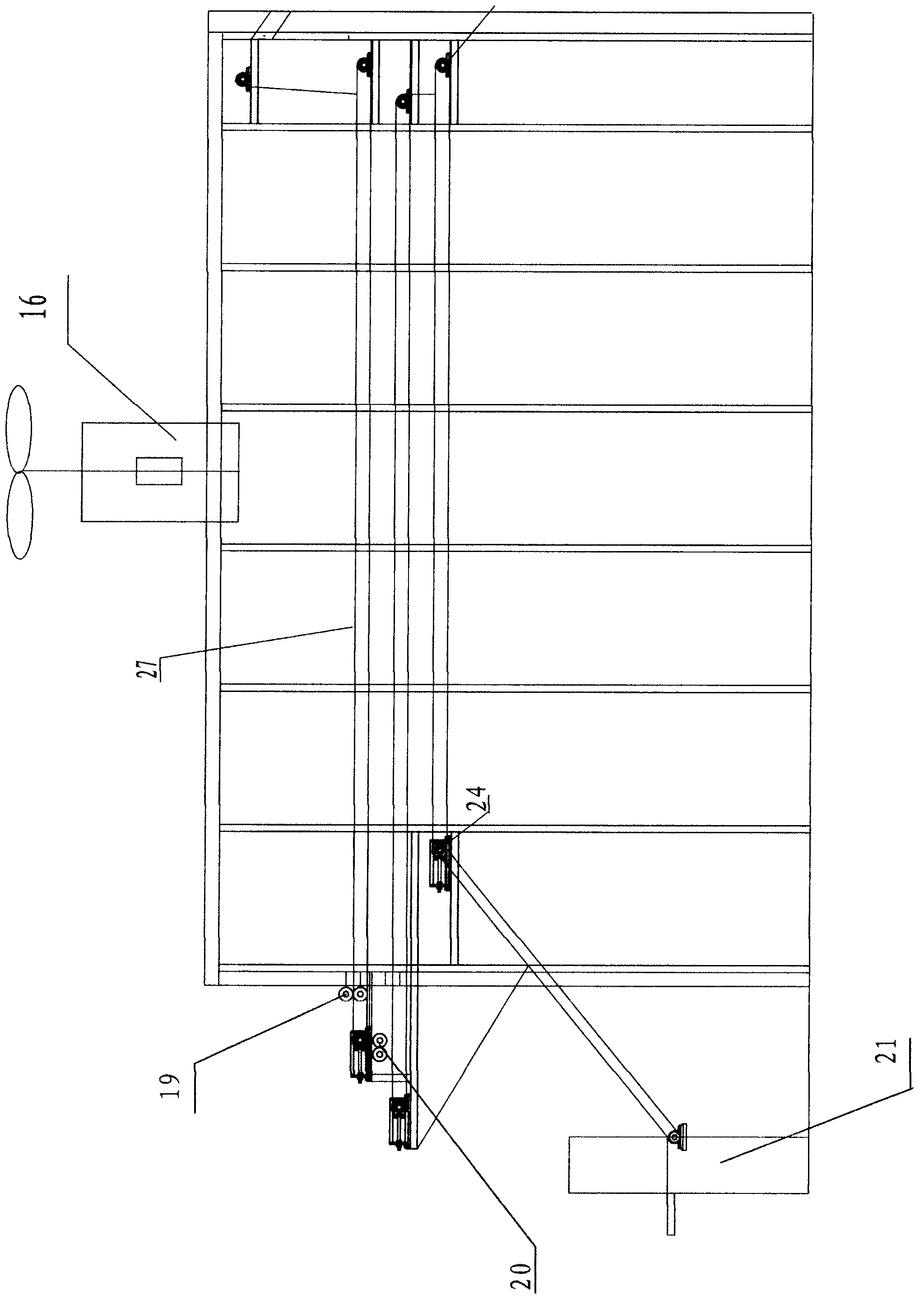

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , figure 2 and image 3 As shown, the motor 1 is fixed under the frame assembly 4 to provide power for the whole equipment, and the powder machine 5, the mixer 6, and the food industry glue booster gear pump 15 are fixed on the top of the frame assembly 4, and the mixer 6 is used The mixer support 7 is fixed, the bottom of the mixer 6 is provided with a hopper 8, the hopper 8 is provided with a funnel 9 and the funnel 9 is connected with the screw extrusion maturation shaft assembly 10, the screw extrusion maturation shaft assembly 10 is fixed with the shaft holder 11, and the screw extrusion One end of the pressing shaft assembly 10 is connected to the motor 1 through the belt 2 and the pulley assembly 3, the other end is connected to the glue booster gear pump 15 through the clinker pipe 12 and the transition pipe A14, and the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com