Sulfydryl-ferrum composite and modified clay and preparation method thereof

A composite modification and sulfhydryl compound technology, applied in the field of environmental pollution remediation, can solve problems such as insufficient detoxification efficiency of materials, and achieve the effects of easy large-scale production, low energy consumption, and low production process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

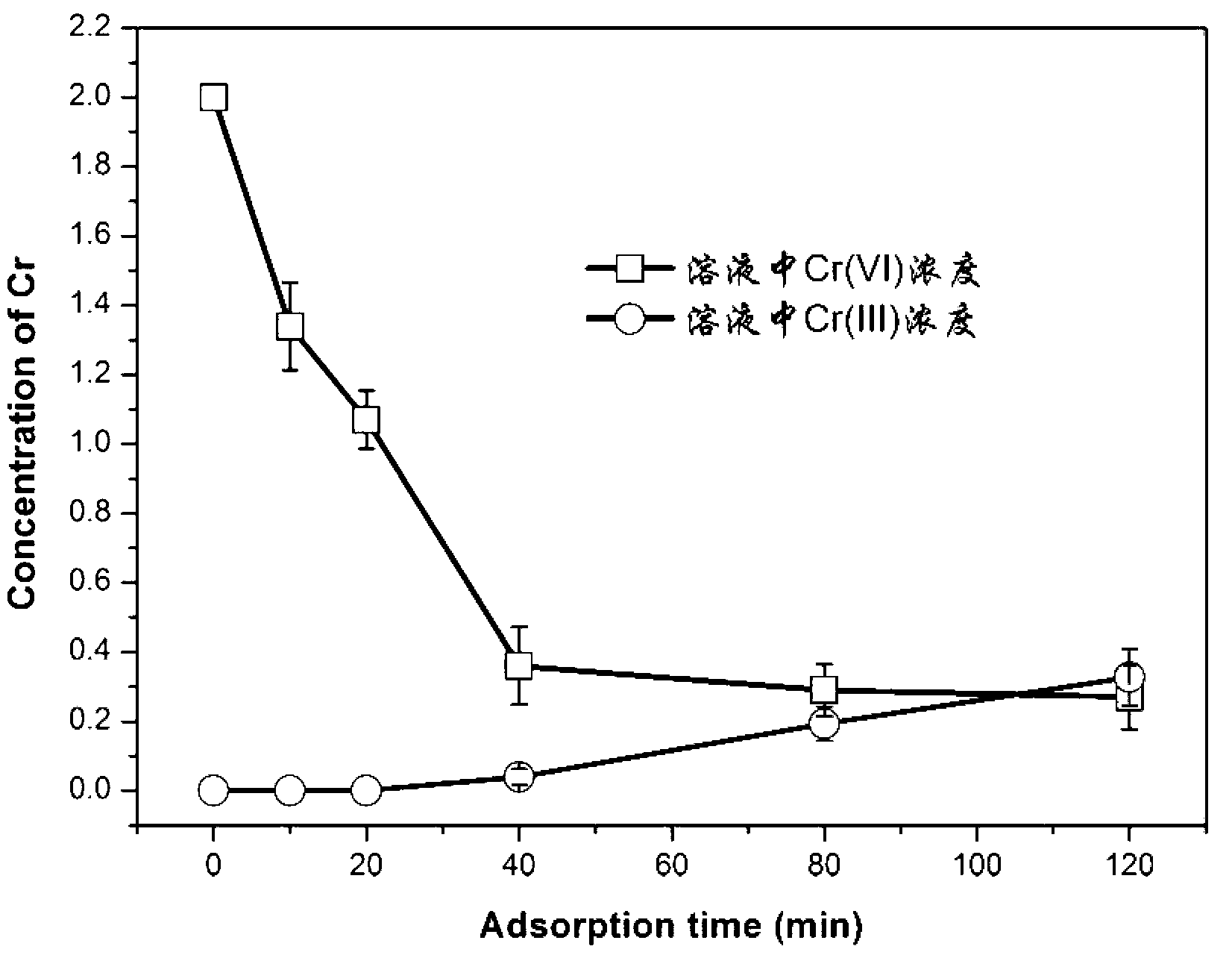

[0025] Example 1: Preparation of mercapto-iron-based composite modified clay using cysteamine hydrochloric acid, ferrous oxalate and bentonite as precursors.

[0026] The preparation of the mercapto-iron-based composite modified clay of this embodiment includes the following steps:

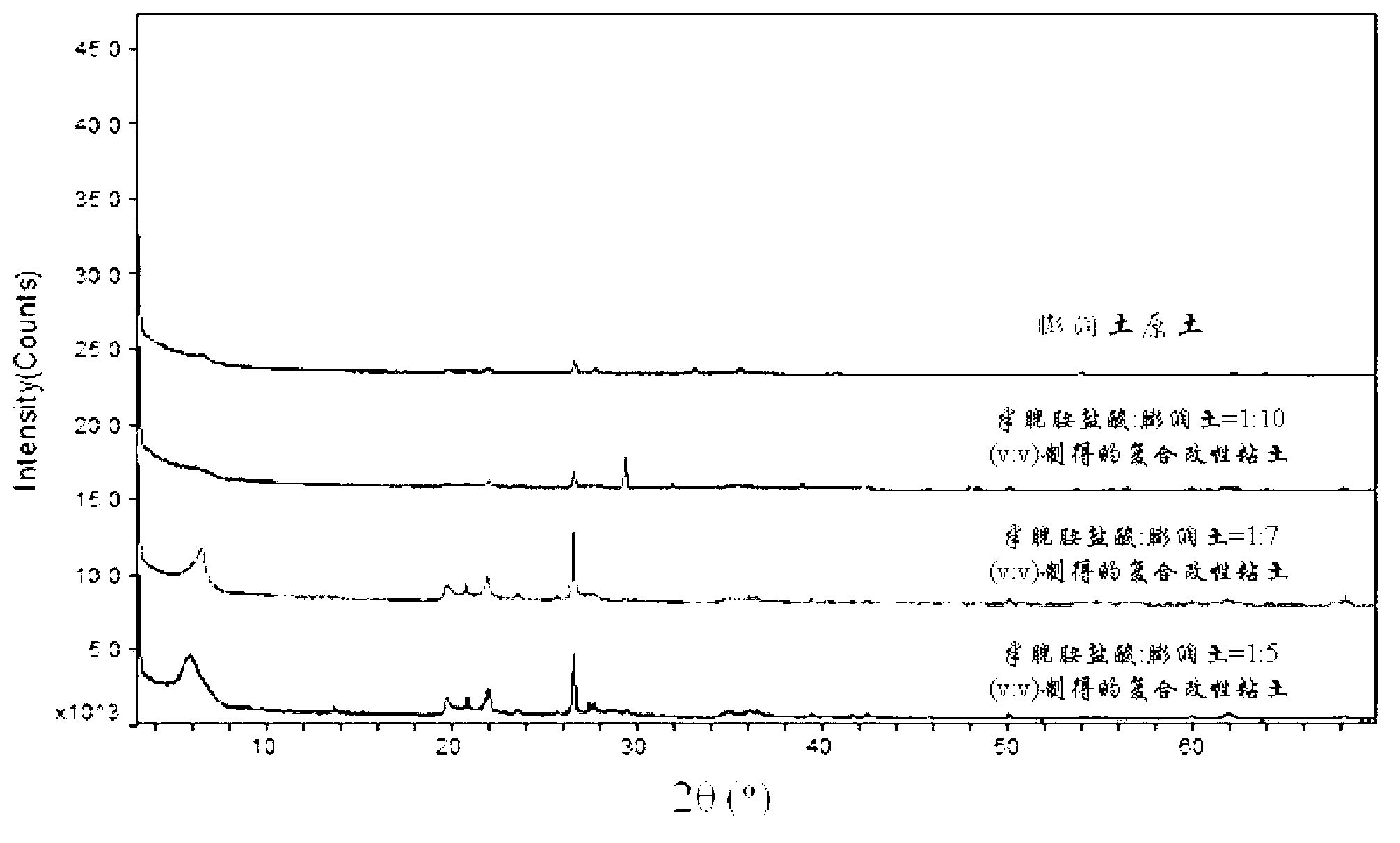

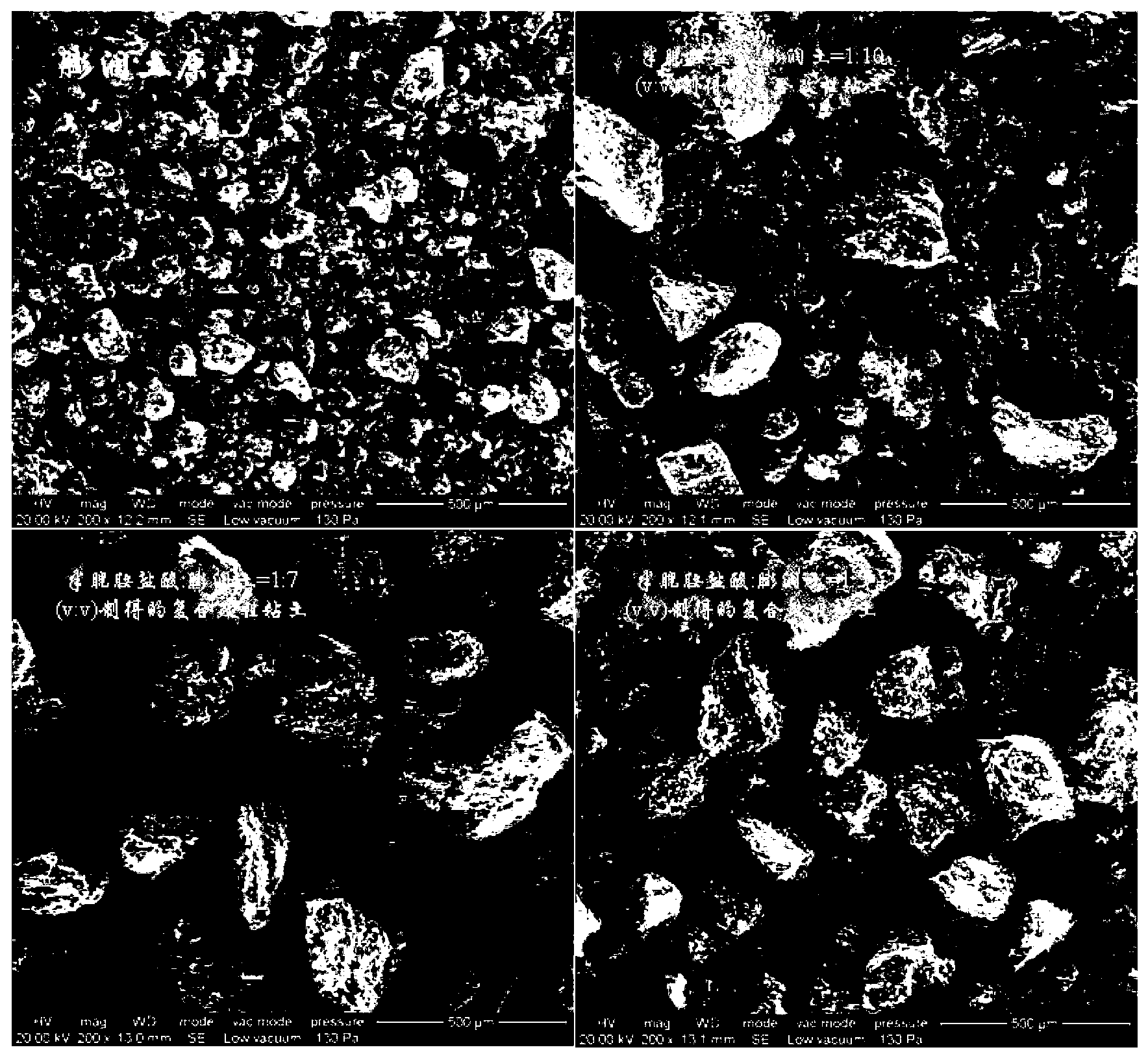

[0027] (1) Mix 0.5 mol / L cysteamine hydrochloric acid aqueous solution and 3% by mass aqueous bentonite suspension in a volume ratio of 1:10, 1:7, and 1:5;

[0028] (2) The samples with different volume ratios of step (1) were stirred and reacted in a mixer for 1.5 hours;

[0029] (3) After the reaction, the sample is centrifuged to remove the upper aqueous solution and retain the solid matter. The solid substance was washed 5 times with distilled water, then dried and ground at 60°C to obtain a powder sample;

[0030] (4) The powdered sample is mixed with water to form a suspension with a mass ratio of 2%, and the suspension is mixed with a 1.0 mol / L ferrous oxalate aqueous solution in a volume ratio of 1...

Embodiment 2

[0037] Example 2: Preparation of mercapto-iron-based composite modified clay using cystine, ferrous citrate and kaolin as precursors.

[0038] The preparation of the mercapto-iron-based composite modified clay of this embodiment includes the following steps:

[0039] (1) Mix the 2.0mol / L cystine aqueous solution with the 1% mass percent kaolin aqueous suspension in a volume ratio of 1:10;

[0040] (2) Stir the mixed sample of step (1) in a mixer for 4 hours;

[0041] (3) After the reaction, the sample is centrifuged to remove the upper aqueous solution and retain the solid matter. The solid substance is washed with distilled water, dried and ground at 40°C to obtain a powder sample;

[0042] (4) The powdered sample is mixed with water to form a suspension with a mass ratio of 2%, and the suspension is mixed with a 2.0mol / L ferrous citrate aqueous solution in a volume ratio of 1:2, 1:3, and 1:5;

[0043] (5) The mixed solution was stirred and reacted for 4 hours and then centrifuged to s...

Embodiment 3

[0048] Example 3: Preparation of mercapto-iron-based composite modified clay with mercaptopropionic acid, ferrous tartrate and montmorillonite as precursors.

[0049] The preparation of the mercapto-iron-based composite modified clay of this embodiment includes the following steps:

[0050] (1) Mix 1.0 mol / L mercaptopropionic acid aqueous solution and 1.5% by mass aqueous montmorillonite suspension in a volume ratio of 1:5;

[0051] (2) Stir the mixed sample of step (1) in a mixer for reaction for 2 hours;

[0052] (3) After the reaction, the sample is centrifuged to remove the upper aqueous solution and retain the solid matter. The solid material is washed with distilled water, dried and ground at 50°C to obtain a powder sample;

[0053] (4) The powdered sample is mixed with water to form a suspension with a mass ratio of 2%, and the suspension is mixed with a 1.5mol / L ferrous tartrate aqueous solution in a volume ratio of 1:3;

[0054] (5) The mixed solution is stirred and reacted for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com