Synthetic method of 1,1,1,3,3-perfluoropropane

A synthesis method and pentafluoropropane technology are applied in the field of preparation of HFC-245fa, can solve the problems of high reaction energy consumption, low energy efficiency, long preparation route and the like, and achieve the effects of simple process, small equipment investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

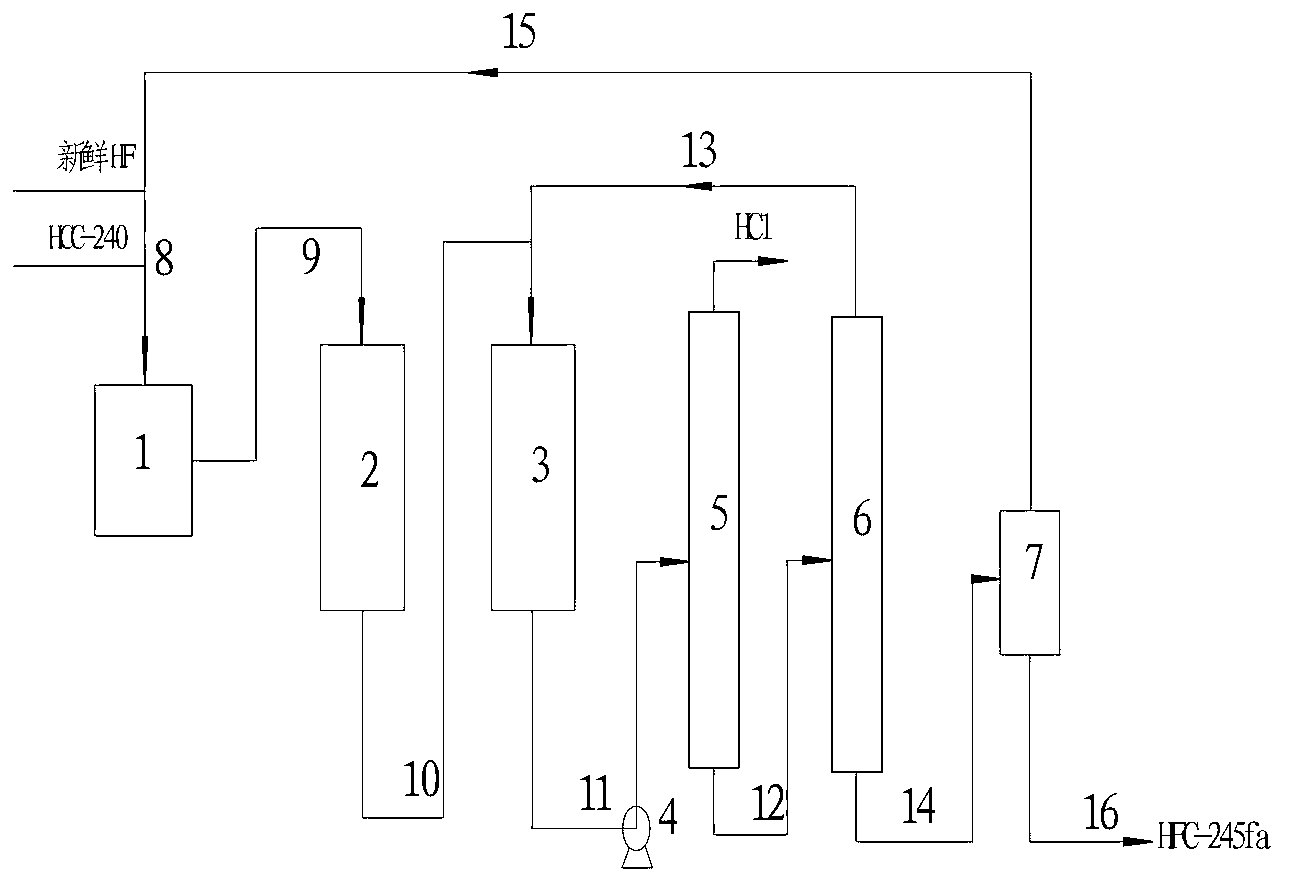

Method used

Image

Examples

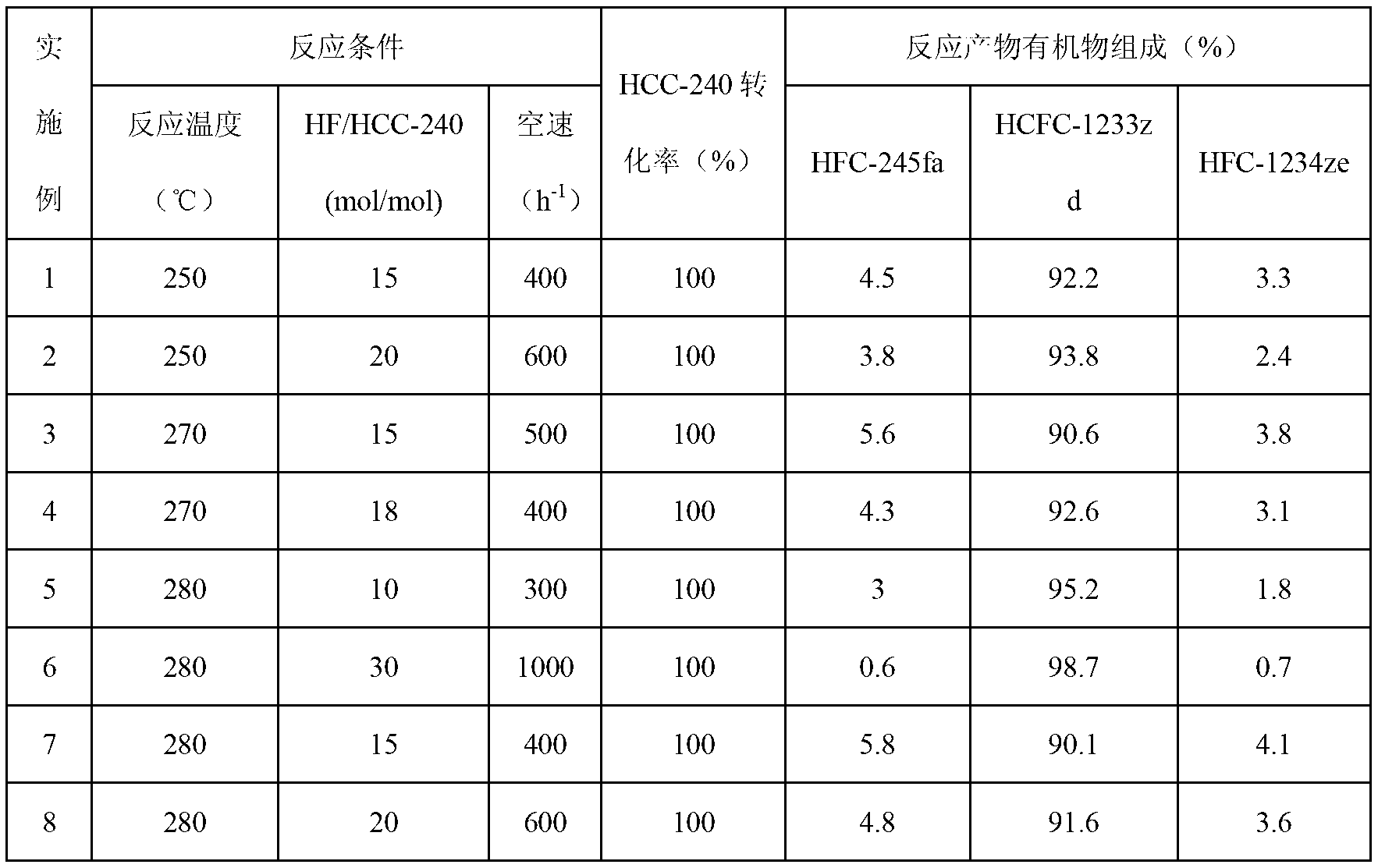

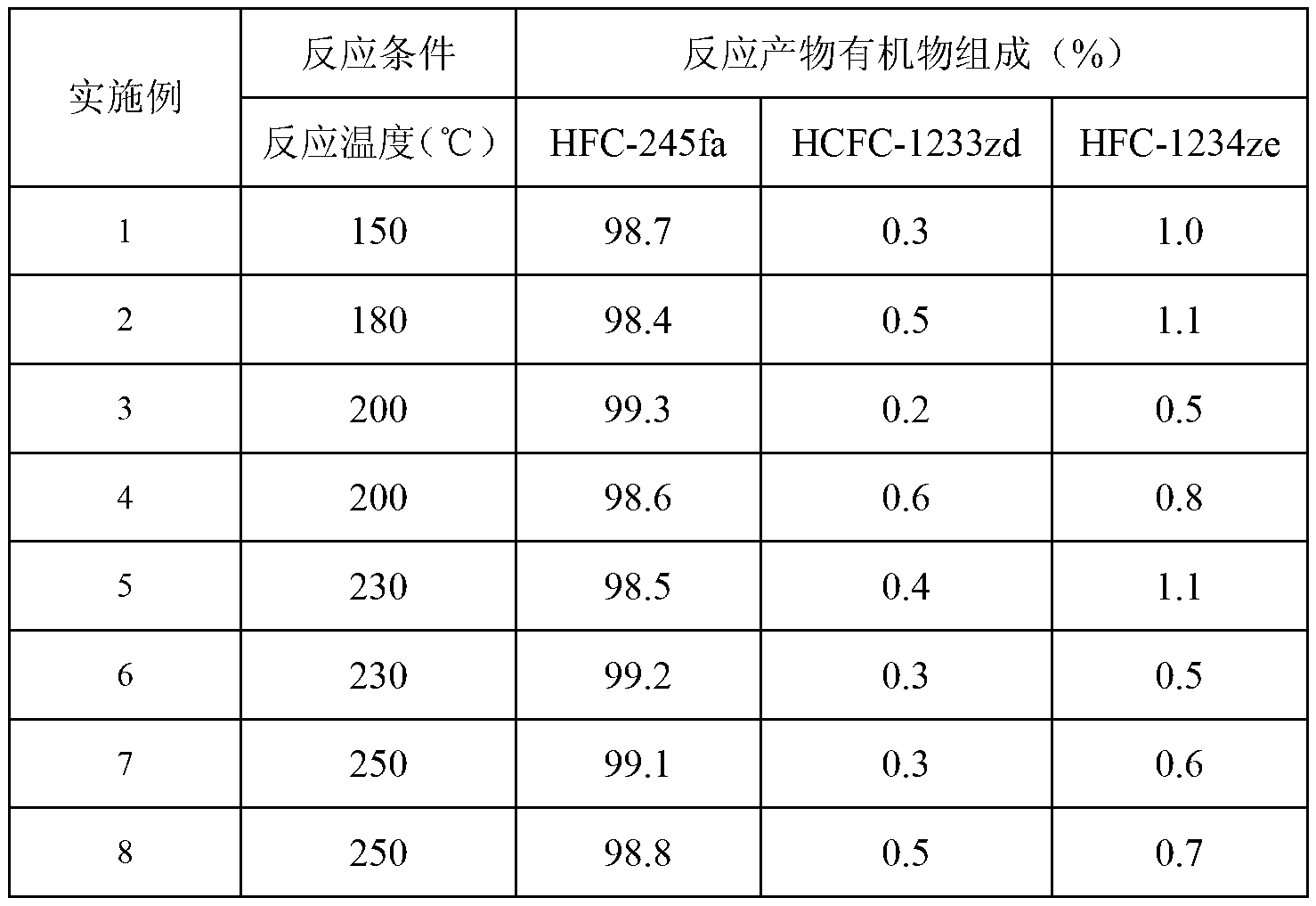

Embodiment 1~8

[0031] Put 150ml of compressed chromium-based catalyst containing aluminum and zinc into the first reactor, raise the temperature to 350°C, pass through nitrogen to dry for 6 hours, then cool down to 260°C, pass through anhydrous hydrogen fluoride diluted with nitrogen to activate Treatment, due to the first pass of hydrogen fluoride, the hot spot of the reactor bed is more obvious, and the hot spot of the catalyst bed is controlled by the amount of nitrogen to not exceed 380°C. After 4 hours of activation, the temperature of the first reactor is raised to 350°C, and shut down Nitrogen is used for activation, and the catalyst activation is completed when there is no water vapor overflowing from the outlet of the reactor, and the entire activation process takes about 48 hours.

[0032] The 150ml compressed chromium-based catalyst containing aluminum and zinc is loaded into the second reactor, and activated according to the activation mode of the first reactor.

[0033] Adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com