Carbon/carbon composite material and preparation method thereof

A technology of carbon composite materials and carbon fiber prefabrication, which is applied in the field of C/C composite materials and its preparation, which can solve the problems of environmental pollution, high synthesis temperature, discharge of a large amount of waste gas or soot particles, and achieve low preparation cost and high reaction temperature. Low, avoid the effect of surface crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1): glucose is dissolved in water to obtain a glucose solution with a concentration of 100g / L;

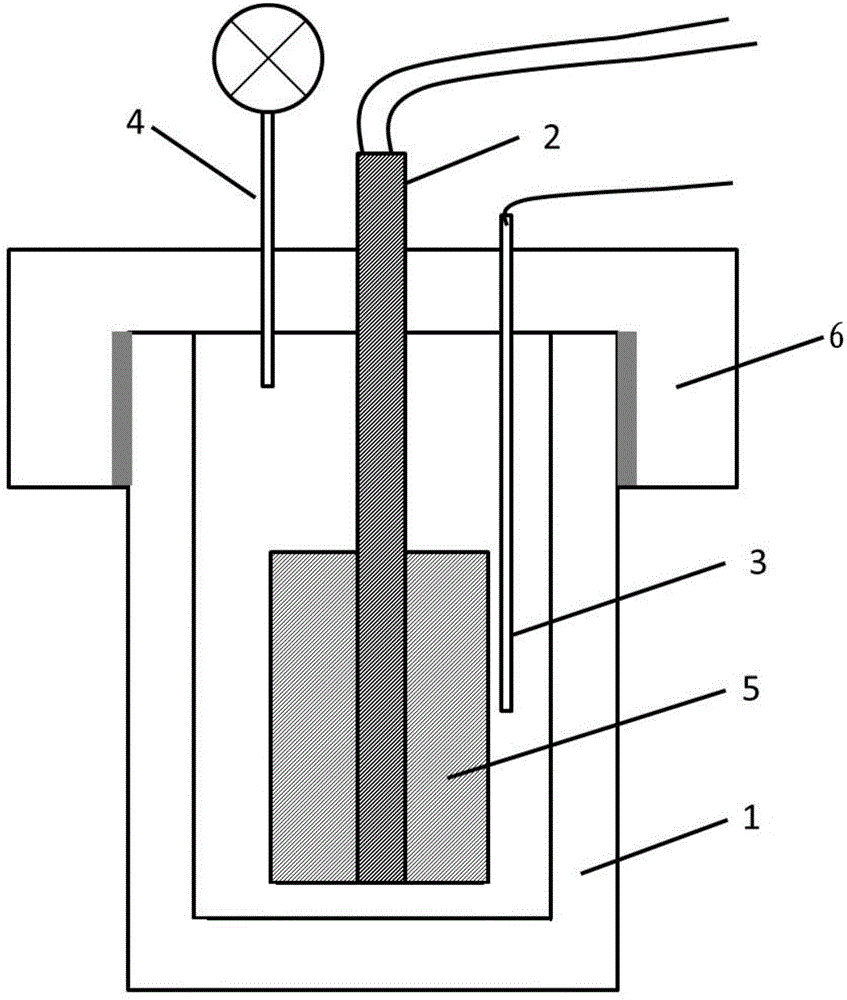

[0033] (2): Set the density to 0.2g / cm 3 The cylindrical overall carbon felt is set on the heating tube; the outer diameter of the cylindrical carbon felt is 1 / 3 of the inner diameter of the reactor.

[0034] (3): Add the glucose solution obtained in step (1) into the reaction kettle, assemble the heating tube with the carbon fiber prefabricated body in step (2) and the reaction kettle, and start the heating reaction. The reaction temperature is controlled at 120°C. The time is controlled at 8h, and the filling ratio is controlled at 0.4.

[0035] (4): Open the reaction kettle after the reaction of step (3), pour out the liquid in the reaction kettle, then add the glucose solution in the step (1), the filling ratio is controlled at 0.4, then heat the reaction, and the reaction temperature is controlled at 120°C, the reaction time is controlled at 8h.

[0036] (5): Repeat...

Embodiment 2

[0039] (1): Dissolving sucrose in water to obtain a sucrose solution with a concentration of 200g / L;

[0040] (2): Set the density to 0.4g / cm 3 The cylindrical carbon fiber needle felt is set on the heating tube, and the outer diameter of the cylindrical carbon fiber needle felt is 1 / 2 of the inner diameter of the reactor.

[0041] (3): Add the sucrose solution obtained in step (1) into the reaction kettle, assemble the heating tube of the carbon fiber prefabricated body in step (2) and the reaction kettle, and start the heating reaction. The reaction temperature is controlled at 150°C, and the reaction time is Controlled at 4h, the filling ratio is controlled at 0.5.

[0042](4): Open the reaction kettle after the reaction of step (3), pour out the liquid in the reaction kettle, then add the sucrose solution in the step (1), the filling ratio is controlled at 0.5, then heat the reaction, and the reaction temperature is controlled at 150°C, the reaction time is controlled at...

Embodiment 3

[0047] (1): Stir the starch in water evenly, and the concentration of the starch in the solution is 300g / L;

[0048] (2): Set the density to 0.2g / cm 3 The cylindrical needle-punched carbon felt is set on the heating tube; the outer diameter of the cylindrical needle-punched carbon felt is 2 / 3 of the inner diameter of the reactor.

[0049] (3): Add the starch solution obtained in step (1) into the reaction kettle, assemble the heating tube with the carbon fiber prefabricated body in step (2) and the reaction kettle, and start the heating reaction. The reaction temperature is controlled at 180°C, and the reaction time is Controlled at 6h, the filling ratio is controlled at 0.6.

[0050] (4): Open the reaction kettle after the reaction of step (3), pour out the liquid in the reaction kettle, then add the starch solution in step (1), the filling ratio is controlled at 0.6, and then heat the reaction, and the reaction temperature is controlled at 160°C, the reaction time is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com