Method for extracting onion osteogenic peptide

An extraction method and technology of osteogenic peptides, which are applied in the fields of peptides, bone diseases, drug combinations, etc., can solve the problems such as the extraction method of onion osteogenic peptides, etc., and achieve the effect of high-efficiency extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

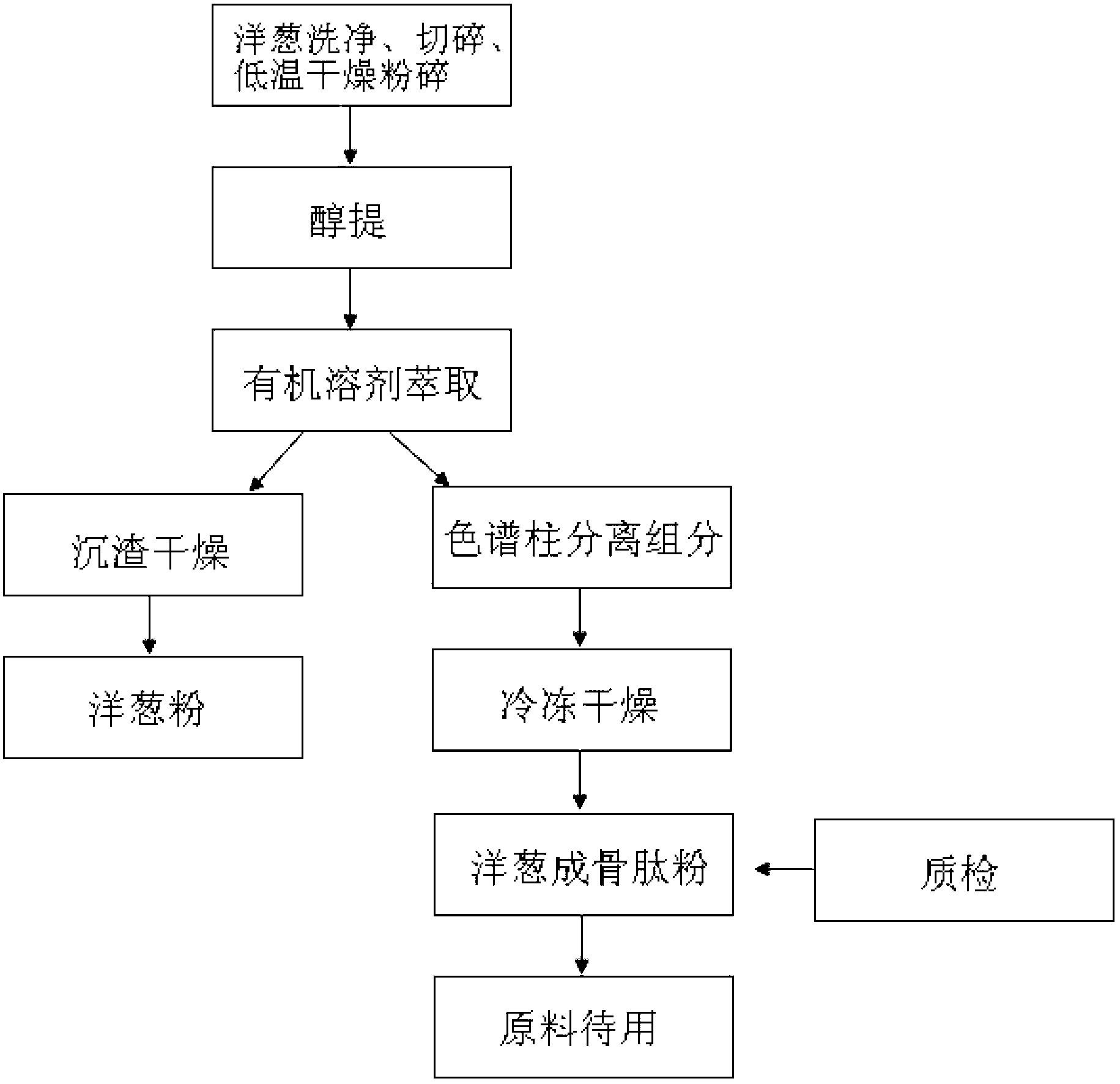

[0033] The schematic diagram of the extraction process of onion osteogenic peptides is as follows figure 1 As shown, the extraction steps are as follows:

[0034] A), take 50kg of fresh purple onion, peel and wash, cut into pieces, dry under the condition of lower than 80 ℃, pulverize and pass through a 60-mesh sieve;

[0035] B), soak with 50L of 75% ethanol (volume concentration) at room temperature for 2 weeks, and use a rotary evaporator to recover ethanol in a water bath below 80°C to obtain 10kg of extract;

[0036] C), dissolve the extract with 25L of pure water, then extract 3 times with 25L of dichloromethane, combine the three aqueous layer solutions, and use a rotary evaporator to recover the dichloromethane in a water bath below 80 ° C to obtain a crude onion polypeptide Extract 1 total 6kg;

[0037] D), put the crude extract 1 of onion polypeptide on the D-101 macroporous resin chromatographic column, and elute with 50% ethanol (volume concentration, the same be...

Embodiment 2

[0046] The schematic diagram of the extraction process of onion osteogenic peptides is as follows figure 1 As shown, the extraction steps are as follows:

[0047] A), take 50kg of fresh purple onion, peel and wash, cut into pieces, dry under the condition of lower than 60 ℃, pulverize and pass through a 60-mesh sieve;

[0048] B), soak with 50L of 75% ethanol at room temperature for 2 weeks, and use a rotary evaporator to recover ethanol in a water bath below 80°C to obtain 10.3kg of extract;

[0049] C), dissolve the extract with 25L of pure water, then extract 3 times with 25L of chloroform, combine the three aqueous layer solutions, and use a rotary evaporator to recover chloroform in a water bath below 80 ° C to obtain onion polypeptide crude extract 1 total 6.1kg;

[0050] D), put the crude extract 1 of onion polypeptide on the D-101 macroporous resin chromatographic column, eluted with 50% ethanol until the column is colorless (about 30L of 50% ethanol), and the eluent...

Embodiment 3

[0057] The schematic diagram of the extraction process of onion osteogenic peptides is as follows figure 1 As shown, the extraction steps are as follows:

[0058] A), take 50kg of fresh purple onion, peel and wash, cut into pieces, dry under the condition of lower than 80 ℃, pulverize and pass through a 60-mesh sieve;

[0059] B), soak with 50L of 75% ethanol at room temperature for 2 weeks, and use a rotary evaporator to recover ethanol in a water bath below 80°C to obtain 9.8kg of extract;

[0060] C), dissolve the extract with 25L of pure water, then extract 3 times with 25L of dichloromethane, combine the three aqueous layer solutions, and use a rotary evaporator to recover the dichloromethane in a water bath below 80 ° C to obtain a crude onion polypeptide Extract 1 total 5.9kg;

[0061] D), put the crude extract 1 of onion polypeptide on the AB-8 macroporous resin chromatographic column, and elute with 50% ethanol until the column is colorless (about 30L of 50% ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com