Preparation method of high-barrier-performance vinylidene chloride and acrylonitrile copolymer latex

A technology of vinylidene chloride and acrylonitrile, which is applied in the field of preparation of high-barrier vinylidene chloride and acrylonitrile copolymer latex, can solve the problems of high crystallinity, poor stability, foaming and the like, and achieve stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 1600g of desalted water, 10.08g of sodium lauryl sulfate, 4.0g of octylphenol oxide vinyl ether, and 100g of seed latex into a 10L kettle, add 400g of vinylidene chloride and 45g of propylene after nitrogen pressure testing and vacuuming Acrylic acid and 5g of acrylic acid mixed monomer, after stirring evenly, the temperature was raised to 50°C, the pressure was 0.035Mpa, 2.0g of tert-butyl hydroperoxide, 3.5g of sodium formaldehyde sulfoxylate, and 0.03g of ferrous chloride solution were added dropwise to start polymerization When the polymerization conversion rate is about 30%, start to drop 400g vinylidene chloride, 45g acrylonitrile and 10g acrylic acid mixed monomer, 8.0g sodium lauryl sulfate and 4.0g octylphenol oxide vinyl ether mixed emulsifier solution, Control the polymerization conversion rate to about 70% and finish adding dropwise, keep the polymerization temperature constant until the polymerization pressure drops to 0.025Mpa, add ammonium laurate and ...

Embodiment 2

[0019] When preparing the copolymer latex, the emulsifier kind is changed into sodium lauryl sulfate and nonylphenol oxide vinyl ether, and the pressure and consumption are the same as in Example 1, and other process conditions are the same as in Example 1, and the copolymer latex is obtained, and the sample analysis The test results are shown in Table 1.

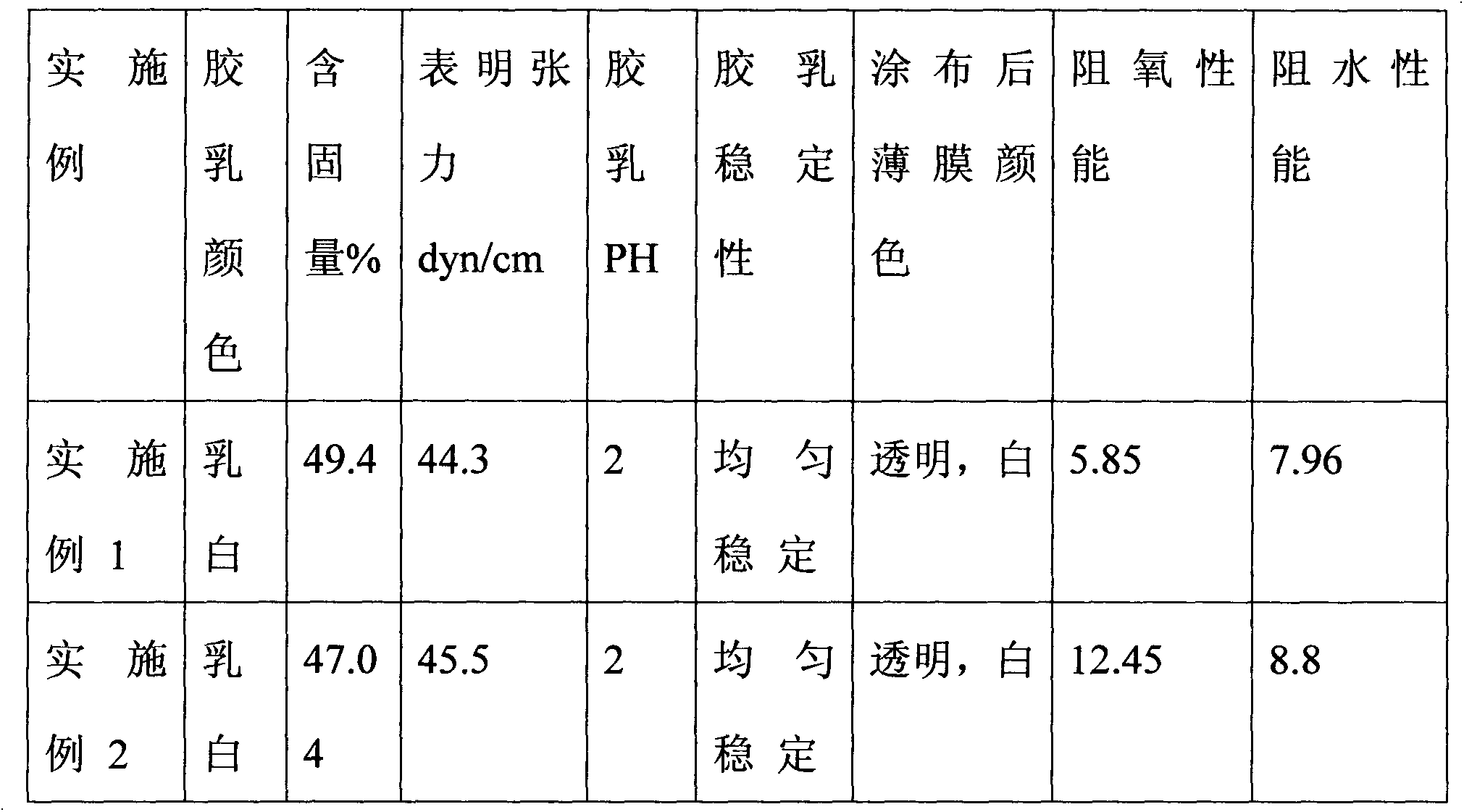

[0020] Table 1

[0021]

[0022] It can be seen from Table 1 that the copolymerized latex of the present invention has a long-term white color, does not turn yellow after coating, and has good stability. The obtained latex can be directly coated on the surface of substrates such as PP, PET, PVDC hard sheets, etc. Or the film formed after coating and drying has barrier properties, moisture resistance, fragrance retention, chemical resistance, flame retardancy, etc., and the coating film is transparent for a long time without yellowing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com