Chitosan polyacrylamide hydrogel base material and preparation method thereof

A polyacrylamide and base material technology, applied in biochemical equipment and methods, tissue culture, microorganisms, etc., can solve problems such as complex research, multiple influencing factors, and single impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

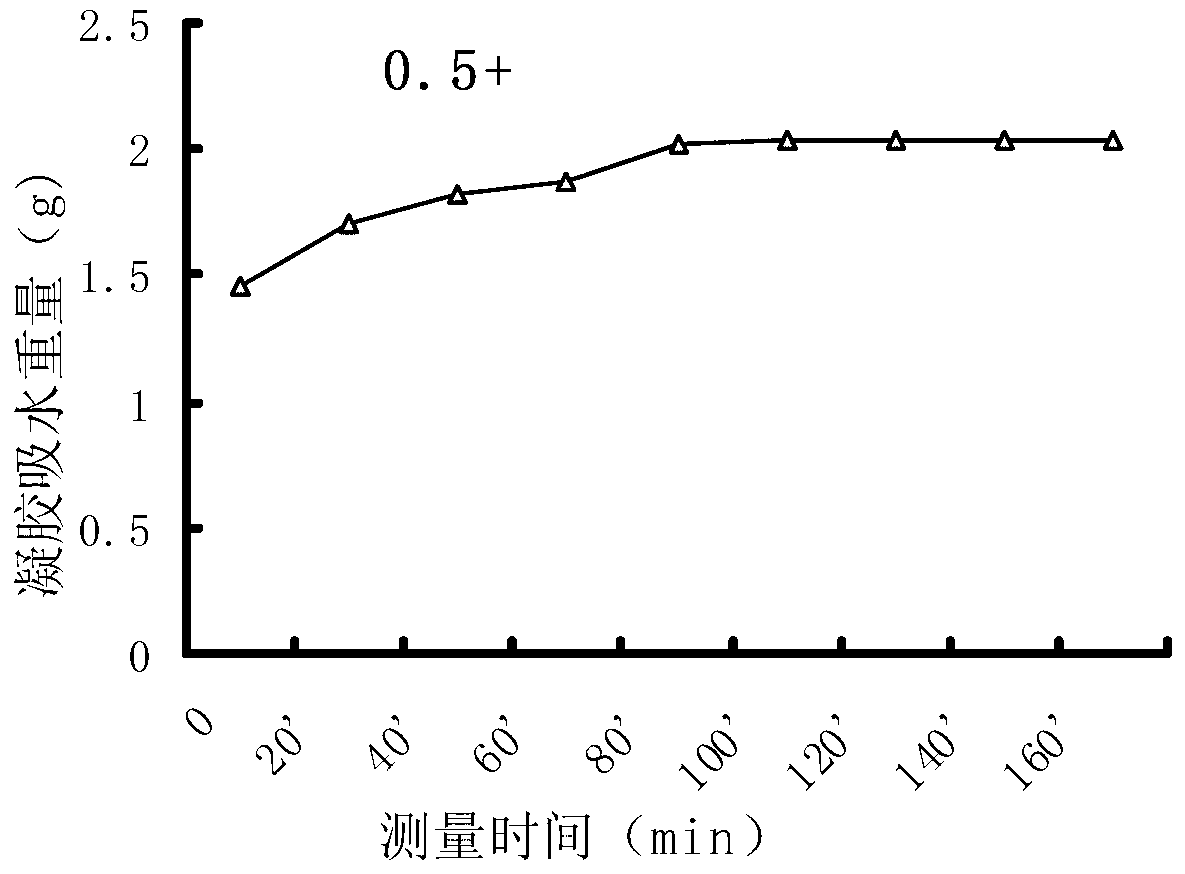

Embodiment 1

[0063] A chitosan polyacrylamide hydrogel base material is composed of the following components in parts by volume:

[0064] 30% (w / v) acrylamide solution: 1.25 parts;

[0065] 1% (w / v) methylene bisacrylamide solution: 0.5 parts;

[0066] h 2 O: 3.25 copies;

[0067] 0.03 parts of ammonium persulfate solution;

[0068] 0.02 part of tetramethylethylenediamine;

[0069] 0.5 parts of 1% (w / v) chitosan solution.

[0070] Prepare 1% (w / v) chitosan solution: add 0.5g chitosan to 50mL 1% acetic acid solution, stir until dissolved at 37°C, and after standing for 24 hours, a 1% (w / v) chitosan solution is obtained .

[0071] A preparation method of chitosan polyacrylamide hydrogel base material, comprising the following steps:

[0072] (1) Mixing and stirring: add 30% (w / v) acrylamide solution, 1% (w / v) methylenebisacrylamide solution, ammonium persulfate solution, tetramethylethylenediamine, 1 % (w / v) chitosan solution is mixed evenly, then added to the centrifuge tube, and st...

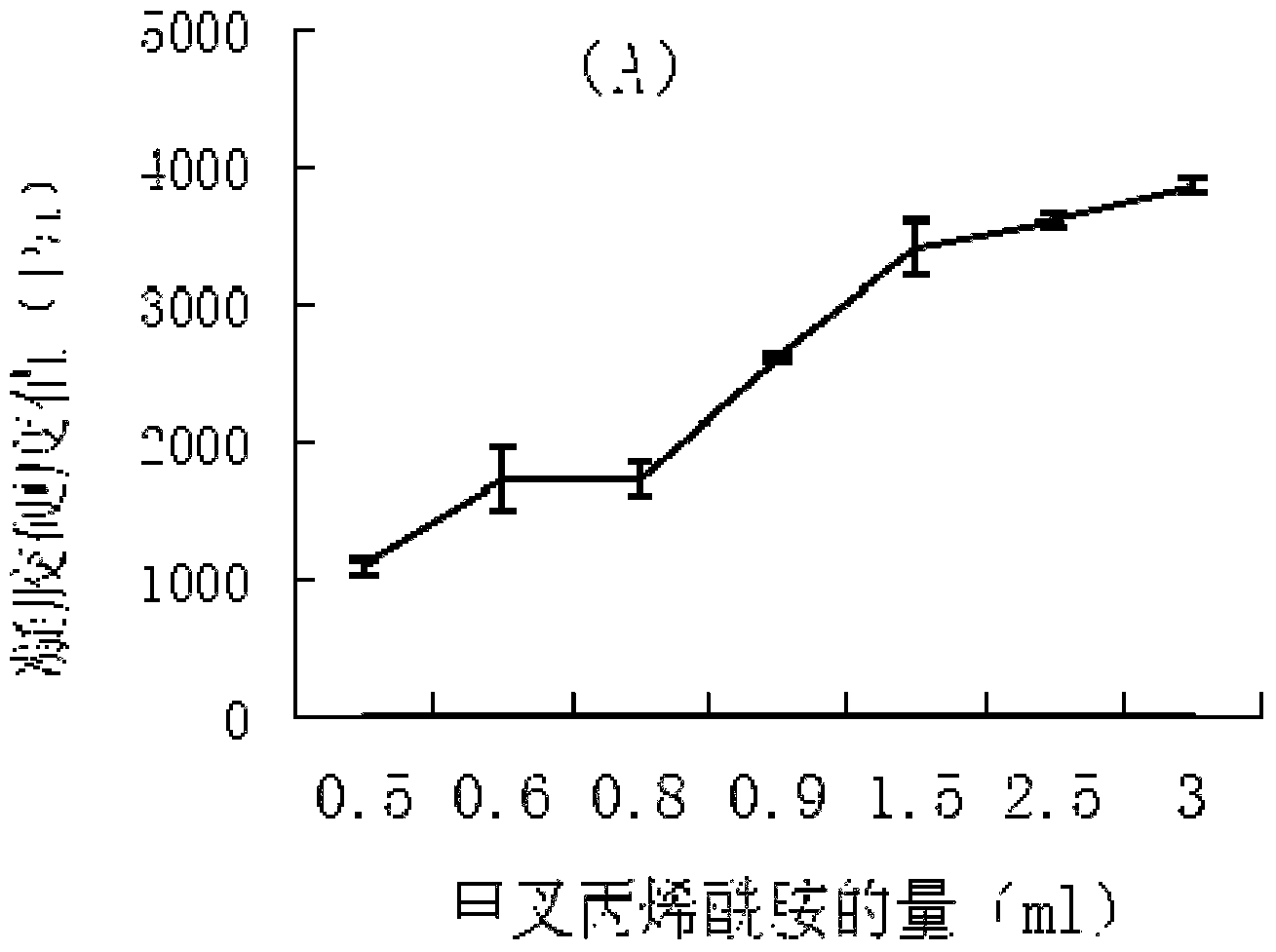

Embodiment 2

[0076] A chitosan polyacrylamide hydrogel base material is composed of the following components in parts by volume:

[0077] 30% (w / v) acrylamide solution: 1.25 parts;

[0078] 1% (w / v) methylene bisacrylamide solution: 3 parts;

[0079] h 2 O: 0.75 parts;

[0080] 0.03 parts of ammonium persulfate solution;

[0081] 0.02 part of tetramethylethylenediamine;

[0082] 0.5 parts of 1% (w / v) chitosan solution.

[0083] Prepare 1% (w / v) chitosan solution: add 0.5g chitosan to 50mL 1% acetic acid solution, stir until dissolved at 37°C, and after standing for 24 hours, a 1% (w / v) chitosan solution is obtained .

[0084] A preparation method of chitosan polyacrylamide hydrogel base material, comprising the following steps:

[0085] (1) Mixing and stirring: add 30% (w / v) acrylamide solution, 1% (w / v) methylenebisacrylamide solution, ammonium persulfate solution, tetramethylethylenediamine, 1 % (w / v) chitosan solution is mixed evenly, then added to the centrifuge tube, and stirr...

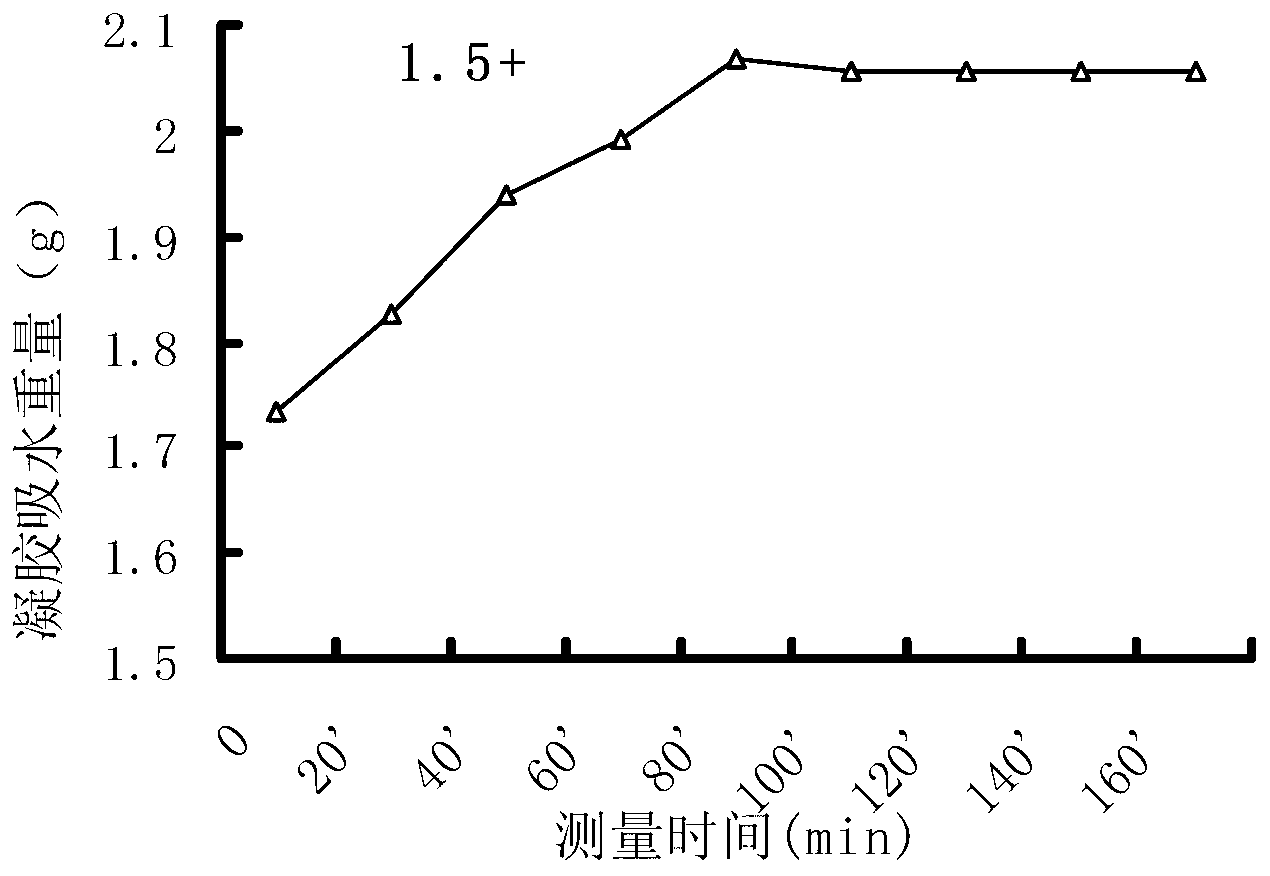

Embodiment 3

[0089] A chitosan polyacrylamide hydrogel base material is composed of the following components in parts by volume:

[0090] 30% (w / v) acrylamide solution: 1.25 parts;

[0091] 1% (w / v) methylene bisacrylamide solution: 1.5 parts;

[0092] h 2 O: 2.25 copies;

[0093] 0.03 parts of ammonium persulfate solution;

[0094] 0.02 part of tetramethylethylenediamine;

[0095] 0.5 parts of 1% (w / v) chitosan solution.

[0096] Prepare 1% (w / v) chitosan solution: add 0.5g chitosan to 50mL 1% acetic acid solution, stir until dissolved at 37°C, and after standing for 24 hours, a 1% (w / v) chitosan solution is obtained .

[0097]A preparation method of chitosan polyacrylamide hydrogel base material, comprising the following steps:

[0098] (1) Mixing and stirring: add 30% (w / v) acrylamide solution, 1% (w / v) methylenebisacrylamide solution, ammonium persulfate solution, tetramethylethylenediamine, 1 % (w / v) chitosan solution is mixed evenly, then added to the centrifuge tube, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com