Yellow UV ink-jet ink for high-speed ink-jet printing and preparation method thereof

An inkjet printing and inkjet ink technology, which is applied in the field of yellow ultraviolet (UV) inkjet ink and its preparation, can solve the problems of ink limitation, can not meet the requirements of high-speed inkjet printing, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

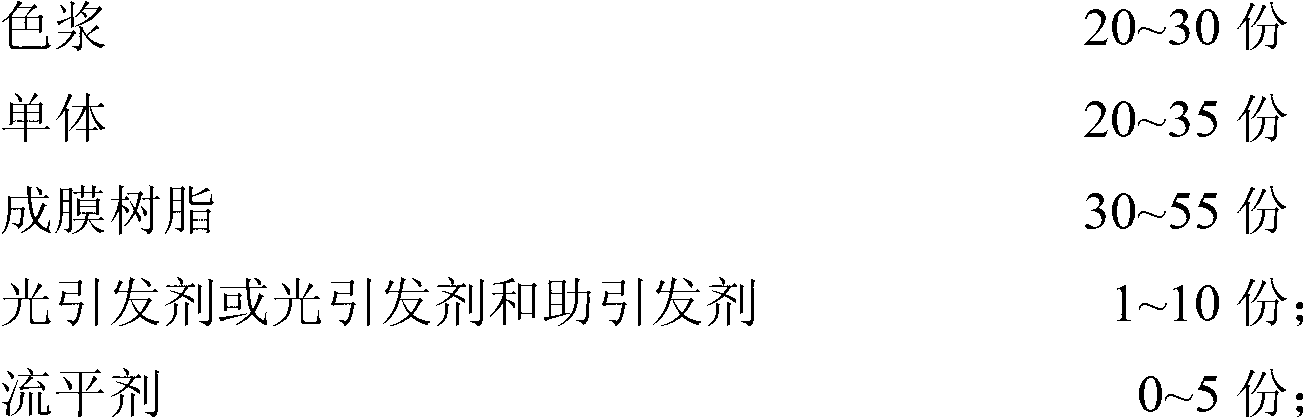

Method used

Image

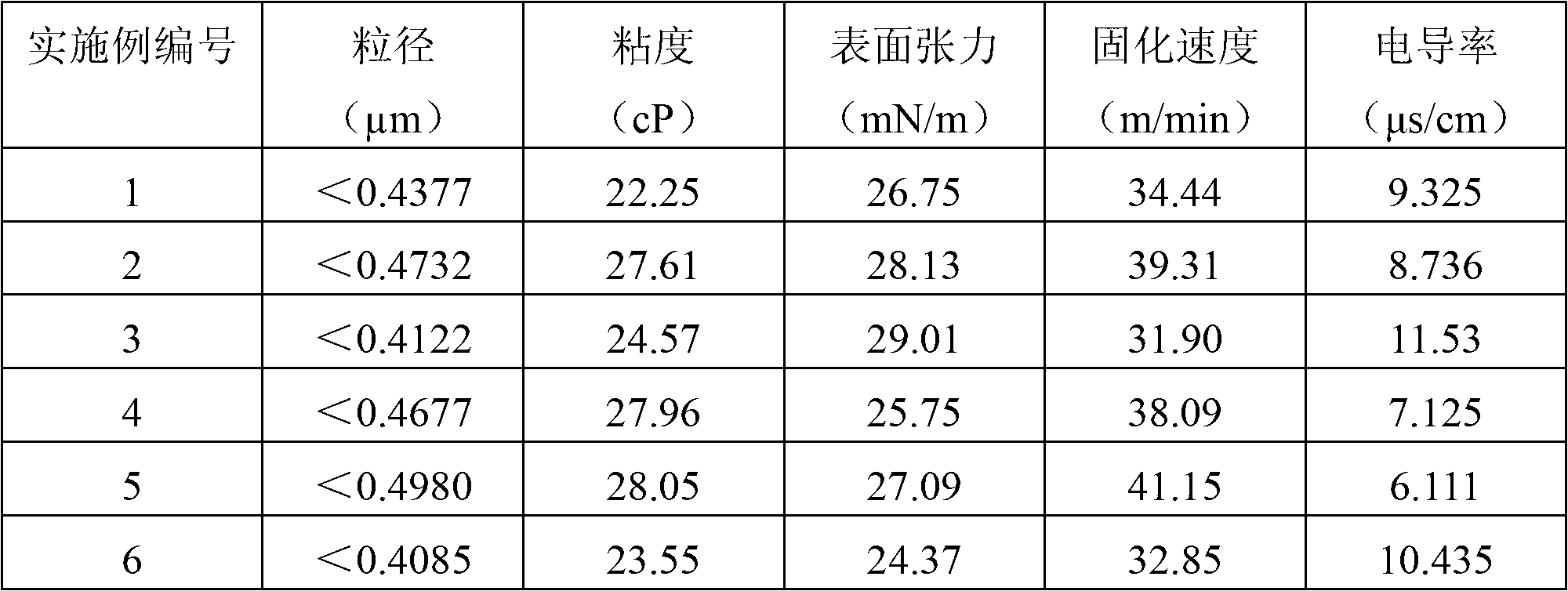

Examples

Embodiment 1

[0031] Mix 30 parts of prepolymer, 40 parts of monomer, and 10 parts of dispersant, place on a constant temperature magnetic stirrer and stir for 30 minutes to mix evenly; add 20 parts of azo yellow, and use a stirrer to stir the mixture for 30 minutes for pre-dispersion , using a high-speed grinder to grind for 60 minutes to obtain a yellow ink color paste. Wherein the azo yellow is selected from Ciba company's micro Korea 3G-K, the prepolymer is a commercially available vinyl acetate resin, and the monomer is commercially available neopentyl glycol diacrylate, tripropylene glycol diacrylate and tripropylene glycol diacrylate. A mixture of methylolpropane triacrylate, the ratio is neopentyl glycol diacrylate: tripropylene glycol diacrylate: trimethylolpropane triacrylate = 9:8:3 (weight ratio), the dispersant is The modified acrylate block copolymer is selected from the disperbyk series of BYK company.

[0032]Mix 25 parts of monomer, 40 parts of film-forming resin, 6 parts ...

Embodiment 2

[0034] Mix 25 parts of prepolymer, 55 parts of monomer, and 5 parts of dispersant, place on a constant temperature magnetic stirrer and stir for 30 minutes to mix evenly; add 15 parts of benzimidazolone yellow, and use a stirrer to stir the mixture for 30 minutes for pre-treatment. After dispersion, use a high-speed grinder to grind for 90 minutes to obtain a yellow ink color paste. Wherein the benzimidazolone yellow is selected from Clariant 180 yellow, the prepolymer is a commercially available polyester acrylic resin, and the monomer is commercially available 2-ethoxyethoxyethyl acrylate, hexanediol diacrylate and ethoxylated trimethylolpropane triacrylate in the ratio 2-ethoxyethoxyethyl acrylate: hexanediol diacrylate: ethoxylated trimethylolpropane triacrylate =5:3:2 (weight ratio), the dispersant is selected from the EFKA series of BASF company.

[0035] Mix 20 parts of monomer, 41 parts of film-forming resin, 4 parts of photoinitiator (including hydrogen donor active ...

Embodiment 3

[0037] Mix 15 parts of prepolymer, 43 parts of monomer, and 12 parts of dispersant, and stir for 20 minutes to mix evenly; add 30 parts of benzidine yellow, use a stirrer to stir the mixture for 40 minutes for pre-dispersion, and use a high-speed grinder to grind 90 Minutes to obtain yellow ink paste. Wherein the benzidine yellow is selected from Ciba's Micro Korea 3R-K, the prepolymer is a commercially available polyester acrylic resin, and the monomer is a commercially available 2-phenoxyethyl acrylate, propoxylated neopentyl A mixture of diol diacrylate and trimethylolpropane trimethacrylate in the ratio 2-phenoxyethyl acrylate:propoxylated neopentyl glycol diacrylate:trimethylolpropane trimethacrylate Base acrylate = 3:3:2 (weight ratio), and the dispersant is byk-168 selected from BYK Company.

[0038] Mix 30 parts of monomer, 48 parts of film-forming resin, 1 part of photoinitiator, and 1 part of leveling agent, add 20 parts of color paste, and stir for 45 minutes with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com