Preparation method of silk fibroin/sodium alginate composite nanofiber scaffold

A technology of composite nanofibers and sodium alginate is applied in the fields of preparation and processing and utilization of fibroin, which can solve the problems of insufficient internal structure and performance of the scaffold, and achieve the effects of good mechanical properties, simple preparation process and easy control of conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Take 5ml of 3% silk fibroin solution, add 10ml of 0.5% sodium alginate solution in a 60°C water bath, and stir evenly with a glass rod.

[0025] (2) Add 5ml of dioxane / water mixture to the mixed solution, and stir well with a glass rod.

[0026] (3) The mixed solution obtained in step (2) was quickly moved into a -80°C refrigerator for aging for 4 hours to cause phase separation of the solution. After taking it out, let it stand at room temperature (25°C) for 30 minutes to form a gel.

[0027] (4) Soak the gel in excess absolute ethanol at -20°C for 24 hours.

[0028] (5) Pour off absolute ethanol, replace with deionized water at 4°C for 48 hours, and change the water continuously during this period.

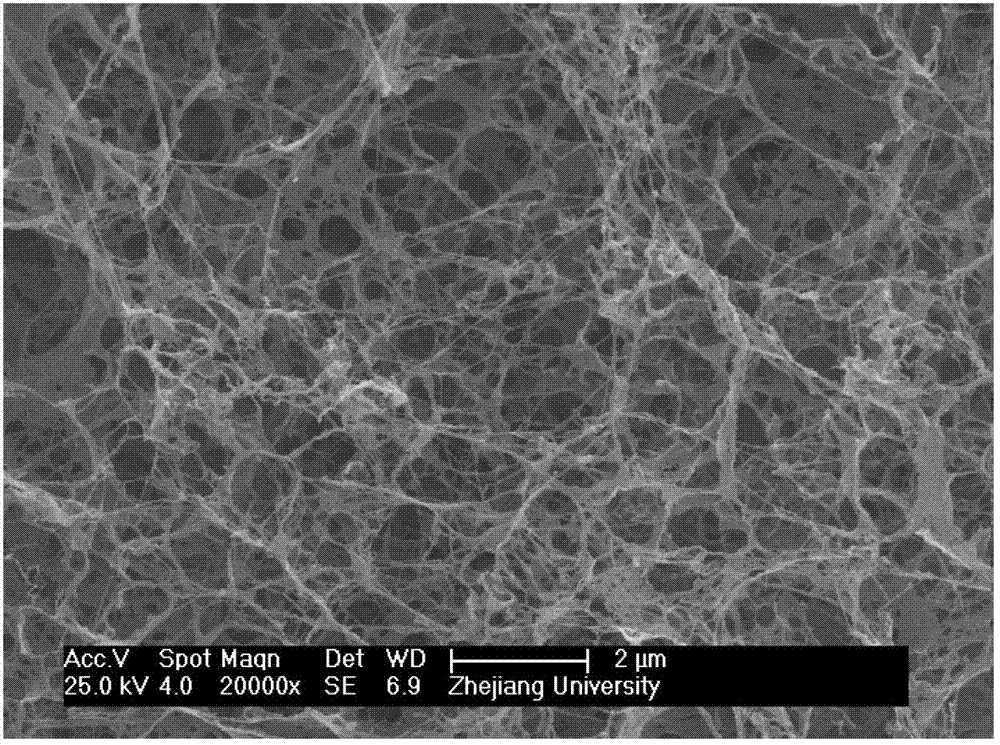

[0029] (6) Pour off the deionized water, put it into a freeze dryer at -60°C for 24 hours, and prepare the silk fibroin / sodium alginate composite nanofibrous scaffold material SF / SA ( figure 1 ), the nanofiber diameter is 20-300nm.

Embodiment 2

[0031] (1) Take 5ml of 5% silk fibroin solution, add 10ml of 0.5% sodium alginate solution in a 60°C water bath, and stir evenly with a glass rod.

[0032] (2) Add 5ml of dioxane / water mixture to the mixed solution, and stir well with a glass rod.

[0033] (3) The mixed solution obtained in step (2) was quickly moved into a -80°C refrigerator for aging for 4 hours to cause phase separation of the solution. After taking it out, let it stand at room temperature (25°C) for 30 minutes to form a gel.

[0034] (4) Soak the gel in excess absolute ethanol at -20°C for 24 hours.

[0035] (5) Pour off absolute ethanol, replace with deionized water at 4°C for 48 hours, and change the water continuously during this period.

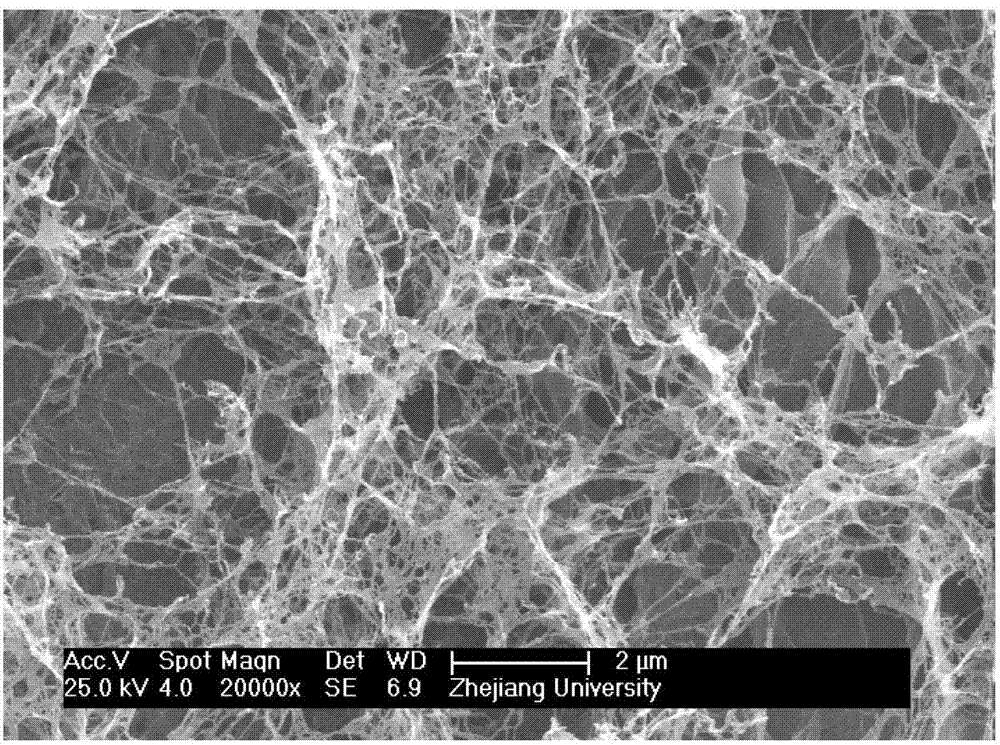

[0036] (6) Pour off the deionized water, put it into a freeze dryer at -60°C for 24 hours, and prepare the silk fibroin / sodium alginate composite nanofibrous scaffold material SF / SA ( figure 2 ), the nanofiber diameter is 40-200nm.

Embodiment 3

[0038] (1) Take 5ml of 7% silk fibroin solution, add 10ml of 0.5% sodium alginate solution in a 60°C water bath, and stir evenly with a glass rod.

[0039] (2) Add 5ml of dioxane / water mixture to the mixed solution, and stir well with a glass rod.

[0040] (3) The mixed solution obtained in step (2) was quickly moved into a -80°C refrigerator for aging for 4 hours to cause phase separation of the solution. After taking it out, let it stand at room temperature (25°C) for 30 minutes to form a gel.

[0041] (4) Soak the gel in excess absolute ethanol at -20°C for 24 hours.

[0042] (5) Pour off absolute ethanol, replace with deionized water at 4°C for 48 hours, and change the water continuously during this period.

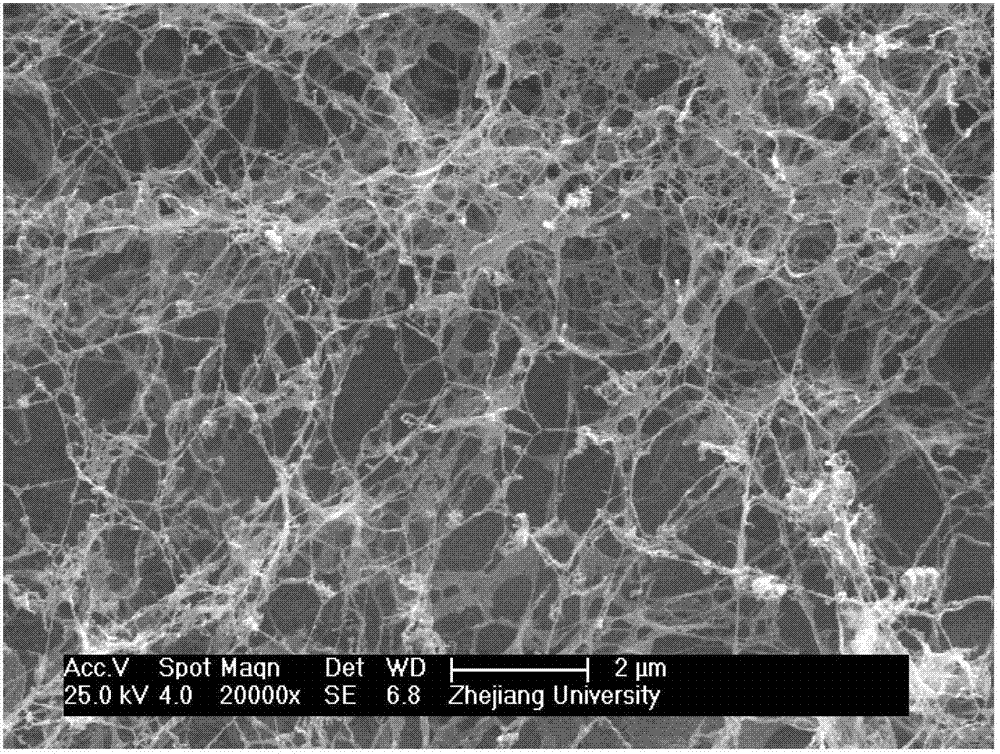

[0043] (6) Pour off the deionized water, put it into a freeze dryer at -60°C for 24 hours, and prepare the silk fibroin / sodium alginate composite nanofibrous scaffold material SF / SA ( image 3 ), the nanofiber diameter is 30-300nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com