Process for analyzing gas-phase total components in cigarette mainstream smoke through airbag-thermal desorption-gas chromatography/mass spectrometry method

A technology for mainstream smoke and thermal desorption of cigarettes, applied in the directions of analysis materials, material separation, measurement devices, etc., can solve the problems of unsatisfactory reproducibility and sensitivity of gas-phase analysis methods, and achieve improved sensitivity and repeatability. Work efficiency, reduce the effect of background signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

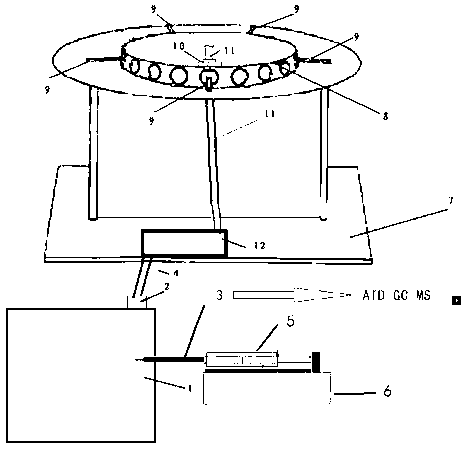

[0041] An airbag-thermal desorption-gas / mass spectrometry method for analyzing the gas-phase complete components in the mainstream smoke of cigarettes is used for qualitative analysis of a certain brand of cigarettes. The method steps are as follows: (the device is as follows figure 1 shown)

[0042] (1) Generate smoke

[0043] Preheat the Borgwaldt200A 20-hole rotary table smoking machine at 22°C±2°C for 20 minutes, adjust the wind speed and suction capacity of the smoking machine, and smoke cigarettes according to ISO standards. The wind speed of the smoking machine is 20cm / s; the suction volume is 35mL, the suction time is 2s / puff, and the interval between each puff is 58s, and the smoke of 20 cigarettes is collected with a Tedler air bag.

[0044] (2) transfer flue gas

[0045]After collecting the smoke of 20 cigarettes with the Tedler air bag, after 2 minutes, use the LSP02-1B syringe pump (the maximum stroke of the syringe pump is 140mm, stroke resolution: 0.156μm, lin...

Embodiment 2

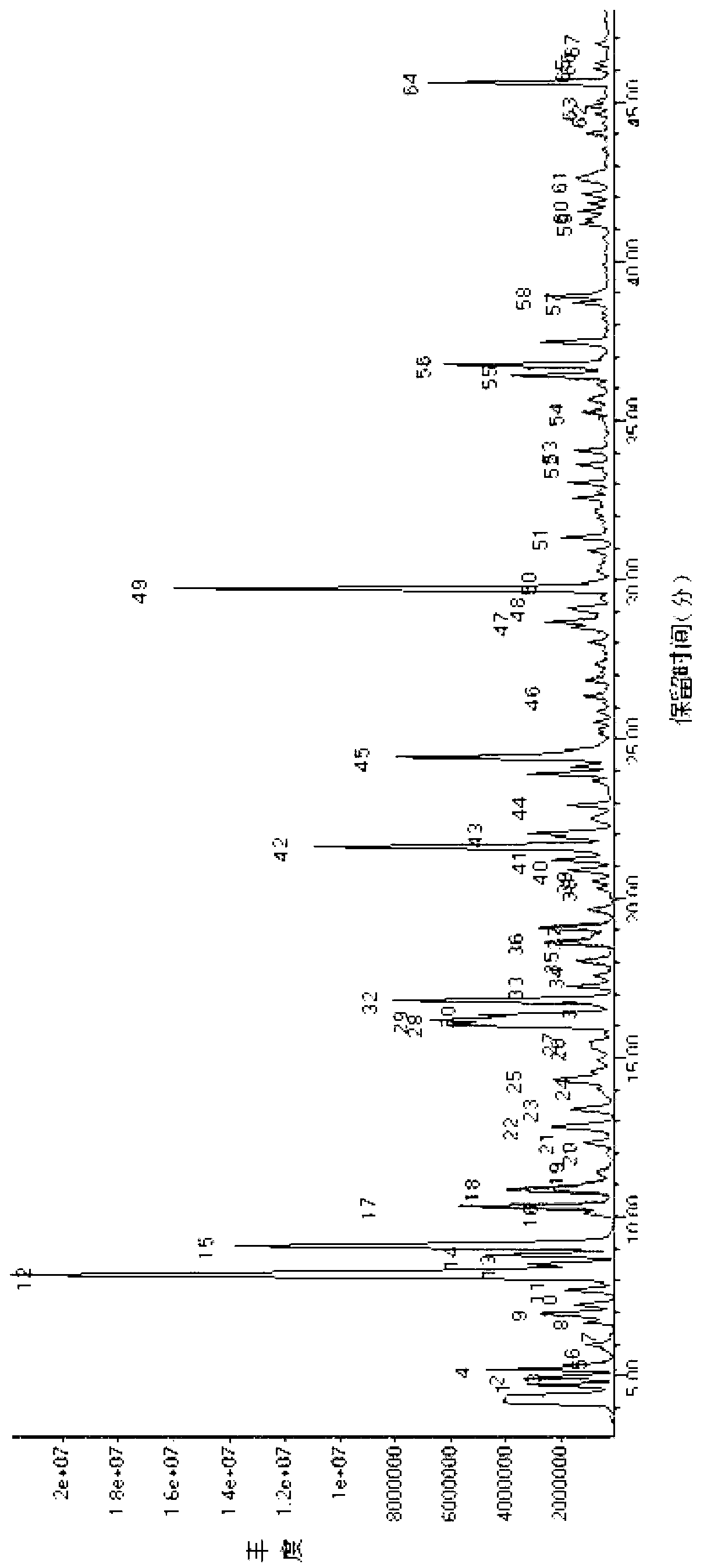

[0058] A method of gas bag-thermal desorption-gas / mass spectrometry to analyze the gas phase components in mainstream cigarette smoke is used to analyze some gas phase components of 2R4F standard cigarettes 1,3-butadiene, isoprene, propylene Qualitative and quantitative analysis of nitrile, benzene, toluene, styrene, acetone, crotonaldehyde, etc., and compared with literature reports:

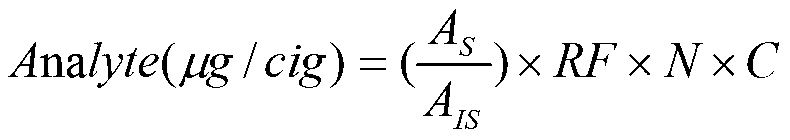

[0059] 1. Preparation of standard working curve

[0060] When the internal standard method is used to quantitatively determine some of the measured components in the gas phase of mainstream smoke, the internal standard substance is deuterated benzene, and the methanol solution with the measured components and internal standard substances is used as the concentration of the working mother solution (level 5 standard solution, see Table 2); the rest of the standard solutions were obtained by serially diluting with methanol. The relative ratio of the concentration of the substance to be measured i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com