Method for preparing beta-enriched Decitabine precursor

A decitabine and precursor technology, which is applied in the field of preparation of decitabine precursors, can solve the problems of high recovery cost, unrefined, large solvent usage, etc., and achieves stable and controllable operation and simple process. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of crude product of decitabine precursor

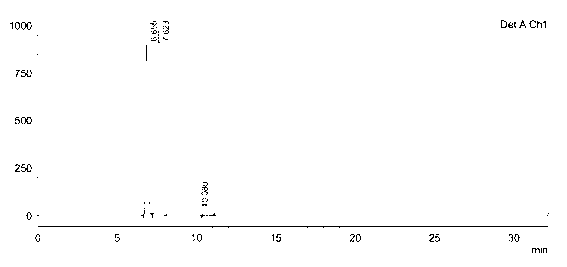

[0033] Add 600g of 5-azacytosine, 6.0g of ammonium sulfate, and 6L of hexamethyldisilazane into a 10L glass reactor in sequence, react at 120°C~125°C under stirring to obtain a clear solution, and concentrate the unreacted Hexamethyldisilazane, the obtained residue was dissolved in 6L of dichloromethane, transferred to a 50L glass reactor, 1L of trimethylsilyl trifluoromethanesulfonate was added at 1~5°C, and then 2kg of 1-chloro -20L dichloromethane solution of -3,5-di-p-chlorobenzoyloxy-2-deoxy-D-ribose, keep warm for 20 hours, add an appropriate amount of saturated sodium bicarbonate solution to terminate the reaction, add 20L dichloromethane to dilute the reaction solution , washed twice with purified water, the organic layer was concentrated under reduced pressure until a large amount of solids were precipitated, filtered, and dried to obtain 2.1 kg of crude decitabine precursor (α / β=1 / 1.2, such a...

Embodiment 2

[0034] Embodiment 2: Preparation of crude product of decitabine precursor

[0035] Add 600g of 5-azacytosine, 6.0g of ammonium sulfate, and 6L of hexamethyldisilazane into a 10L glass reactor in sequence, and react at 125~130°C under stirring to a clear solution, and concentrate the unreacted hexamethyldisilazane under reduced pressure. Methyldisilazane, the obtained residue was dissolved in 6L of dichloromethane, transferred to a 50L glass reactor, 1L of trimethylsilyl trifluoromethanesulfonate was added at 5~10°C, and then 2kg of 1-chloro- 20L dichloromethane solution of 3,5-di-p-chlorobenzoyloxy-2-deoxy-D-ribose, keep warm for 20h, add an appropriate amount of saturated sodium bicarbonate solution to terminate the reaction, add 20L dichloromethane to dilute the reaction solution, Washed twice with purified water, the organic layer was concentrated under reduced pressure until a large amount of solids precipitated, filtered and dried to obtain 2.1 kg of crude decitabine pre...

Embodiment 3

[0036] Example 3: Preparation of β-enriched decitabine precursor

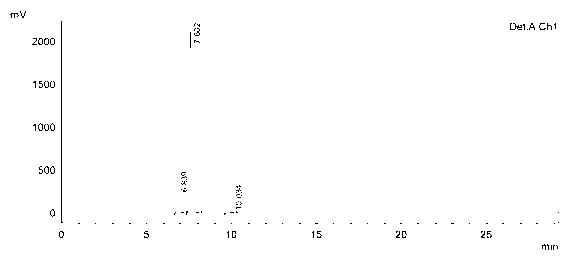

[0037] Add 500g of the crude decitabine precursor prepared in Example 1 into a 20L glass reactor, add 10L of a mixed solvent of water / ethanol (V / V)=1 / 10, heat to reflux, and then let stand at about 25°C Cool and crystallize for 12 hours (precipitate α-enriched body), filter, concentrate the filtrate to near dryness under reduced pressure, filter, and vacuum-dry the filter cake to obtain 254 g of β-enriched decitabine (α / β=1 / 11, such as figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com