A method for preparing fucoidan and fucoxanthin by enzymatic method

A technology of fucoxanthin and fucoidan, applied in the directions of organic chemistry, fermentation, etc., can solve the problems of low efficiency, need to be improved, waste of resources, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of fucoidan and fucoxanthin from dried kelp

[0041] (1) Take 100 Kg of dried kelp, remove sand and sundries, dry, pulverize, and sieve through 80 meshes to make kelp dry powder;

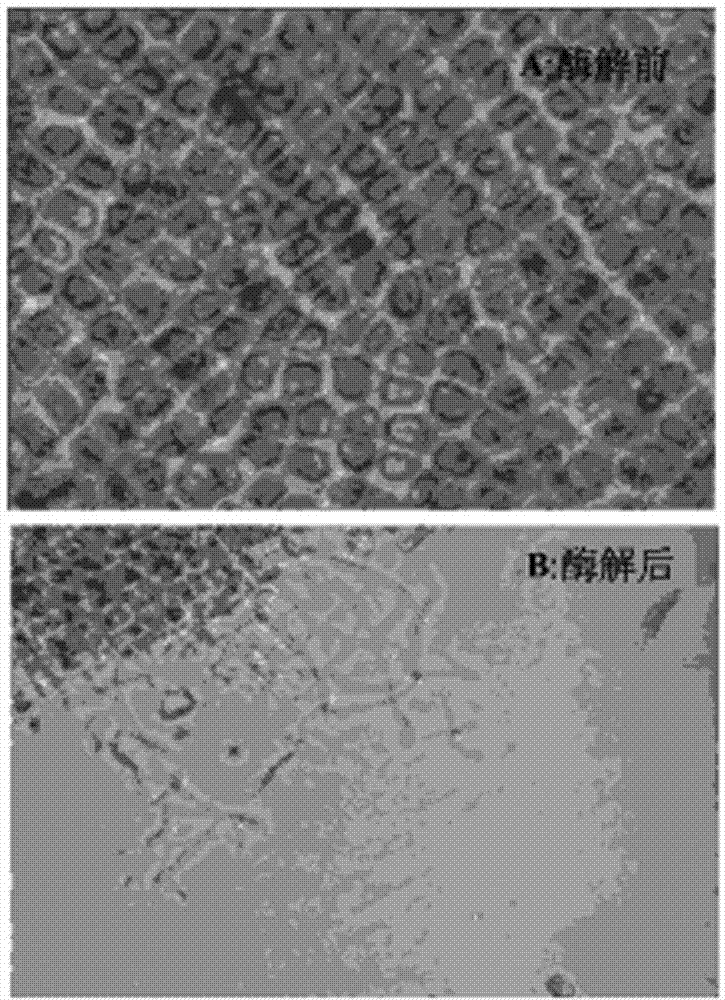

[0042] (2) Take 50 Kg of the above dry kelp powder and mix well with 25 g of compound enzyme, add 750 L of deionized water, and stir evenly. After reacting for 5 h at room temperature at 20 °C, centrifuge in a tubular continuous centrifuge (10,000 rpm for 10 minutes) to obtain about 400 Kg of supernatant and 400 Kg of kelp residue. In this step, the brown algae is treated with biological enzymes to break the wall, so that the fucoidan and fucoxanthin in the brown algae can be fully dissolved, thereby significantly improving the extraction efficiency. The damage effect of biological enzymes on the cell wall of brown algae was observed by optical microscope (see figure 1 ). Depend on figure 1 It can be seen that before the enzyme treatment, the cells of the brown al...

Embodiment 2

[0051] Example 2: Preparation of fucoidan and fucoxanthin from dried wakame

[0052] (1) Take 100 Kg of dried wakame, remove sand and sundries, dry, pulverize, and sieve through 80 meshes to make dry wakame powder;

[0053] (2) Mix 50 Kg of the above dry wakame powder with 100 g of compound enzyme, add 1000 L of deionized water, and mix well. After reacting for 7 hours at room temperature at 20°C, centrifuge in a tubular continuous centrifuge (10,000 rpm for 10 minutes) to obtain about 600 Kg of supernatant and 450 Kg of wakame residue;

[0054] (3) Add 900 L of deionized water to the above wakame residue, extract and centrifuge under the above conditions, the extraction time is 2 hours, and the supernatant liquid is about 900 Kg, and the wakame residue is about 300 Kg;

[0055] (4) The two supernatants were combined, concentrated hydrochloric acid (HCl) was adjusted to a concentration of 4 mol / L, and added to the supernatant in proportion to make the HCl concentration reach...

Embodiment 3

[0061] Example 3: Preparation of Fucoidan and Fucoxanthin from Dried Hijiki

[0062] (1) Take 100 Kg of dried hijiki, remove sand and sundries, dry, pulverize, and sieve through 80 meshes to make hijiki dry powder;

[0063] (2) Take 50 Kg of the above-mentioned hijiki dry powder and 5 g of compound enzyme and mix well, add 1250 L of deionized water, and stir evenly. After reacting for 8 hours at room temperature at 20°C, centrifuge in a tubular continuous centrifuge (10,000 rpm, 10 minutes) to obtain about 920 Kg of supernatant and 380 Kg of hijiki dregs;

[0064] (3) Add 800 L of deionized water to the above-mentioned hijiki dregs, extract and centrifuge under the above conditions, the extraction time is 2 hours, and the supernatant liquid is about 900 Kg, and the hijiki dregs are about 280 Kg;

[0065] (4) The two supernatants were combined, concentrated hydrochloric acid (HCl) was adjusted to a concentration of 4 mol / L, and added to the supernatant in proportion to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com