Preparation method of mung bean extraction liquid with antioxidation activity

An anti-oxidant activity and extraction technology, which is applied in the direction of cosmetic preparations, skin care preparations, cosmetics, etc., can solve the problems of cumbersome preparation process, unfavorable environmental protection in the later stage, and damage to the edibility of residues, etc. Increased production efficiency, good total antioxidant activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

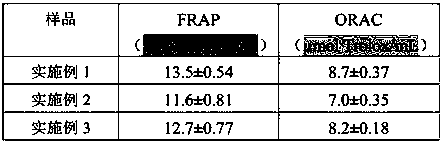

Examples

Embodiment 1

[0026] The preparation method of the mung bean extract with antioxidant activity comprises the following steps:

[0027] Step 1. Select 100 kg of mung bean raw materials that are sieved to remove impurities, remove broken grains, and have a protein content of 21.5%, which meets the requirements of the national "Mung Bean" quality standard (GB 5009.5-2016). Rinse 3 times with water twice the weight of mung bean raw materials, After draining, place it in a flour mill to make powder, and pass through a 60-mesh sieve to obtain mung bean powder, which is mixed with water to obtain mung bean milk. The specific method is: adjust the rotation speed to 1500rpm for shear dispersion, and the dispersion time is 10min;

[0028] Step 2: Add 43.0 g of neutral protease to the mung bean milk (that is, the mass ratio of neutral protease to the total amount of protein in the mung bean raw material is 0.2:100), stir and enzymolyze at 43°C for 5 hours, then centrifuge in a decanter Machine is car...

Embodiment 2

[0032] The preparation method of the mung bean extract with antioxidant activity comprises the following steps:

[0033] Step 1. Select 150 kg of mung bean raw materials that are sieved to remove impurities, remove the broken grains, and have a protein content of 22.1%, which meets the requirements of the national "Mung Bean" quality standard (GB 5009.5-2016). Rinse 3 times with water that is 2.5 times the weight of the mung bean raw material, After draining, place it in a flour mill to make powder, and pass through a 60-mesh sieve to obtain mung bean powder, which is mixed with water to obtain mung bean milk. The specific method is: adjust the rotation speed to 1800rpm for shear dispersion, and the dispersion time is 15min;

[0034]Step 2: Add 199g of neutral protease to the mung bean milk (that is, the mass ratio of the neutral protease to the total amount of protein in the mung bean raw material is 0.6:100), stir and enzymolyze at 46°C for 6 hours, then use a decanter centr...

Embodiment 3

[0038] The preparation method of the mung bean extract with antioxidant activity comprises the following steps:

[0039] Step 1. Select 50 kg of mung bean raw materials that are sieved to remove impurities, remove the broken grains, and have a protein content of 22.5%, which meets the requirements of the national "Mung Bean" quality standard (GB 5009.5-2016). Rinse twice with water that is 3 times the weight of the mung bean raw material, After draining, place it in a flour mill to make powder, and pass through a 60-mesh sieve to obtain mung bean powder, which is mixed with water to obtain mung bean milk. The specific method is: adjust the rotation speed to 2000rpm for shear dispersion, and the dispersion time is 20min;

[0040] Step 2: Add 112.5 g of neutral protease to the mung bean milk (that is, the mass ratio of neutral protease to the total amount of protein in the mung bean raw material is 1:100), stir and enzymolyze at 50°C for 7 hours, then centrifuge in a decanter m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com