Aluminum-gallium alloy and preparation method thereof

A technology of aluminum-gallium alloy and aluminum alloy, which is applied in the field of alloy and its preparation, can solve problems such as uneconomical, large proportion of metal gallium, complicated process, etc., and achieve the goal of eliminating subsequent processing steps, simple preparation process, and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 60g of gallium metal and put it in a closed flask, put the closed flask into a water bath and heat it to 50°C to melt the gallium metal in the bottle into a liquid state, and keep the temperature for later use. Take a square industrial-grade pure aluminum sheet with a length of 50 mm, a width of 50 mm, and a thickness of 2 mm. Under the protection of an argon medium, use a diamond blade to remove the surface oxide film. Continue to pour the above-mentioned liquid gallium on the surface of the exposed pure aluminum substrate under the protection of argon, and the coverage ratio is 30% of the surface area of the exposed pure aluminum substrate. Put the aluminum sheet covered with metal gallium into a vacuum heating furnace, and keep it warm at 50°C for 10 minutes to obtain an aluminum-gallium alloy.

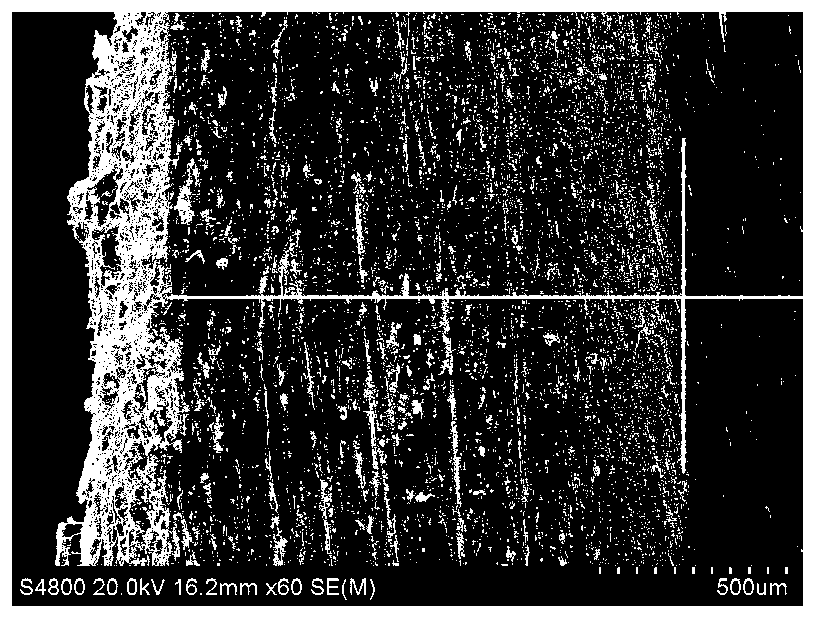

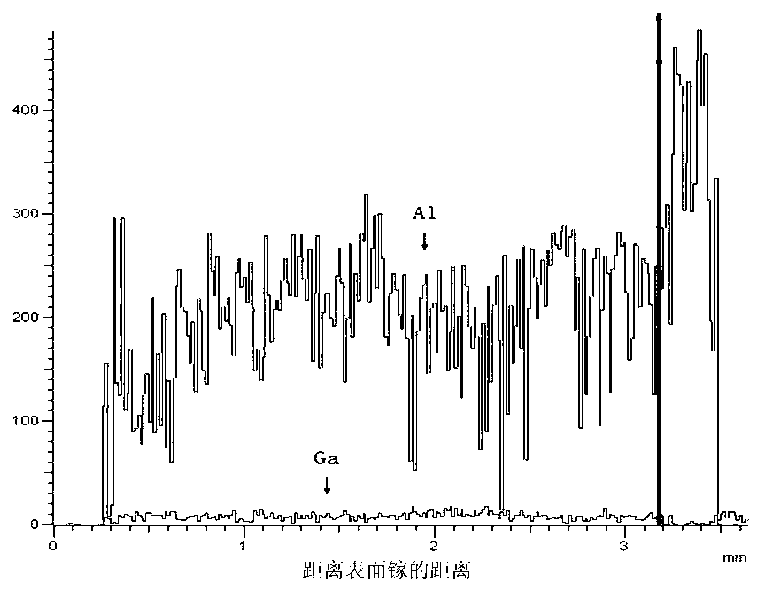

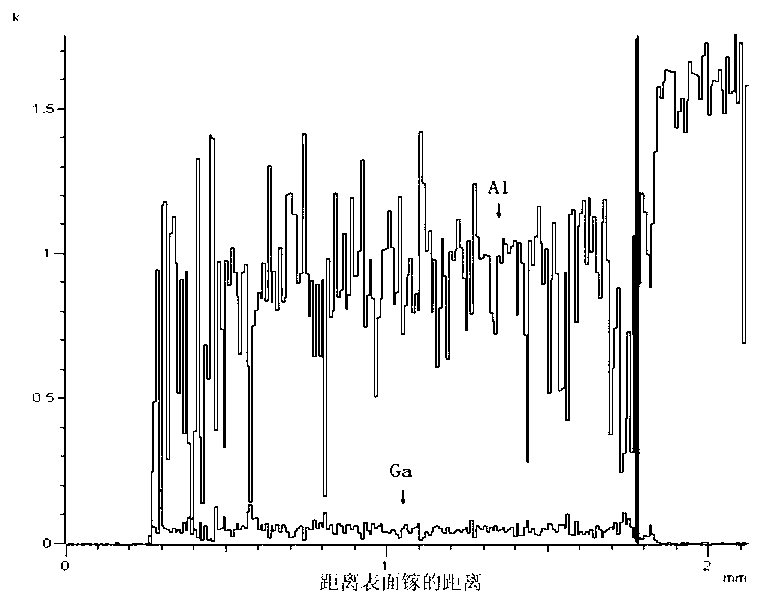

[0024] figure 1 Shown is the 60-fold scanning electron microscope image of the cross-section of the prepared aluminum-gallium alloy. The vertical line in the figure ...

Embodiment 2

[0026] Take 60g of gallium metal and put it in a closed flask, put the closed flask into a water bath and heat it to 100°C to melt the gallium metal in the bottle to a liquid state, and keep the temperature for later use. Take a square metal aluminum sheet with a length of 50 mm, a width of 50 mm, and a thickness of 3 mm. Under the protection of a nitrogen medium, use a diamond blade to remove the surface oxide film. Continue to pour the above-mentioned liquid gallium on the surface of the exposed pure aluminum substrate under the protection of nitrogen, and the coverage ratio is 50% of the surface area of the exposed pure aluminum substrate. Put the aluminum sheet covered with metal gallium into a vacuum heating furnace and keep it warm at 100°C for 20 minutes to obtain an aluminum-gallium alloy.

[0027] Figure 4 Shown is the 35-fold scanning electron microscope image of the fabricated aluminum-gallium alloy cross-section. The vertical line in the figure is the dividing ...

Embodiment 3

[0029] Take 60g of gallium metal and put it in a closed flask, put the closed flask into a water bath and heat it to 50°C to melt the gallium metal in the bottle into a liquid state, and keep the temperature for later use. Take a square industrial-grade pure aluminum sheet with a length of 50 mm, a width of 50 mm, and a thickness of 0.1 mm. Under the protection of an argon medium, use a diamond blade to remove the surface oxide film. Continue to pour the above-mentioned liquid gallium on the surface of the exposed pure aluminum substrate under the protection of argon, and the coverage ratio is 10% of the surface area of the exposed pure aluminum substrate. Put the aluminum sheet covered with metal gallium into a vacuum heating furnace and keep it warm at 50°C for 20 minutes to obtain an aluminum-gallium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com