Method for carrying out configuration optimization on chemical mechanical grinding fluid

A chemical-mechanical and configuration-optimized technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as high cost and long cycle time, and achieve the effect of simplifying the optimization process, reducing process optimization cost and cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

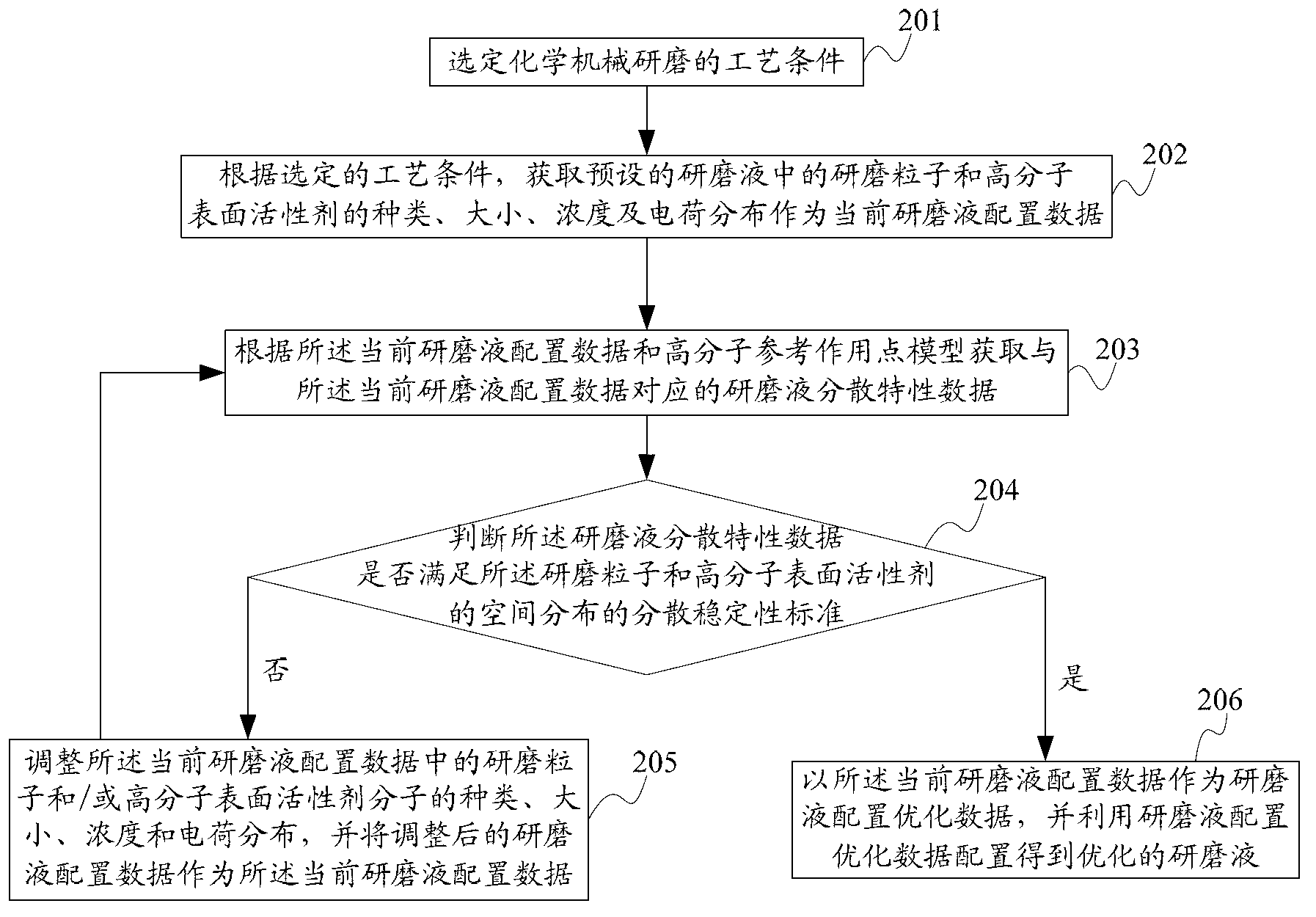

[0116] Step 601, adjust the type of abrasive particles: fix the polymer surfactant configuration data and the concentration, size, and charge distribution of the abrasive particles in the current configuration data, adjust the type of abrasive particles, and then return to step 203 for analysis, and judge by step 204, if not If the dispersion stability standard is used, then continue to adjust the type of abrasive particles until step 204 judges that the dispersion stability standard is satisfied, and the obtained type of abrasive particle is used as the optimized type of abrasive particle, and the process proceeds to step 602 .

[0117] Step 602, adjust the concentration of abrasive particles: fix the polymer surfactant configuration data, abrasive particle size, charge distribution, and optimized abrasive particle types, adjust the concentration of abrasive particles, and then return to step 203 for analysis, judged by step 204, as If the standard of dispersion stability is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com