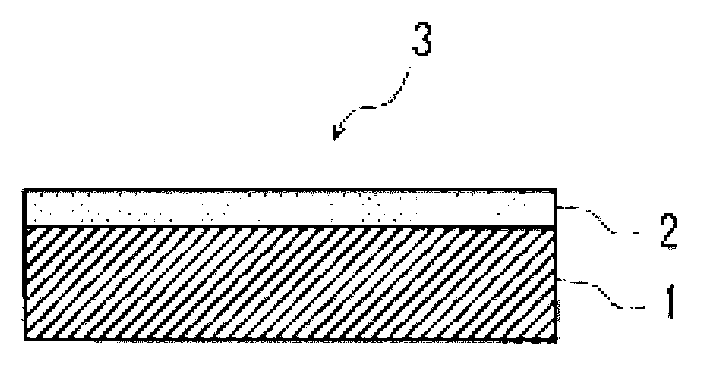

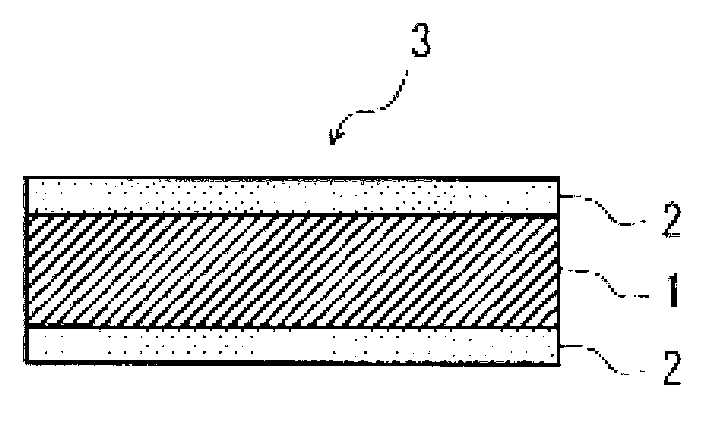

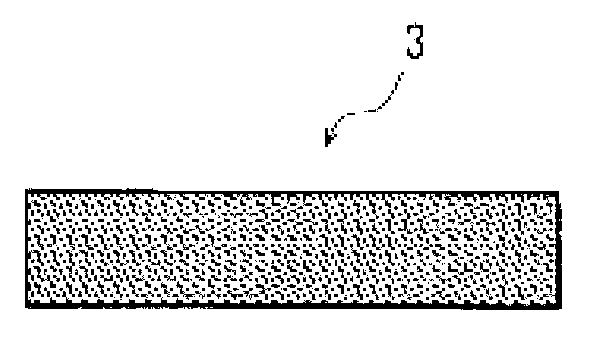

Light-diffusing non-ombustible composite member

A composite component, light diffusivity technology, applied in optical elements, optics, light guides, etc., can solve the problems of low incombustibility, easy cracking, insufficient incombustibility of light diffusing sheets, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099]Add 15 g of a colloidal silica solution (trade name: SNOWTEX OS, manufactured by NISSAN CHEMICAL INDUSTRIES, LTD., solid content concentration 20 nm) with an average particle diameter of 8-11 nm in a container equipped with a stirrer, a reflux condenser, and a nitrogen gas introduction pipe. %), 15g 2-propanol, 5g 2-methoxyethanol. Add concentrated nitric acid to adjust the acidity (pH) of the liquid to the range of 2-4. Then, after raising the temperature to 60° C., 35 g of a silsesquioxane compound (trade name: X-40-9225, Shin-Etsu Chemical Co. Co., Ltd., 24% methoxyl group) dissolved in 35 g of 2-propanol to react the silsesquioxane compound and the surface of colloidal silica particles. After heating and stirring at 100° C. for 1 hour, it was cooled to room temperature (25° C.), and the solvent was distilled off and concentrated under reduced pressure. To this solution, 0.05 g of a catalyst (trade name "CAT-AC", manufactured by Shin-Etsu Chemical Co., Ltd.) was add...

Embodiment 2

[0102] A silicon coating agent (a solvent-free inorganic paint based on organopolysiloxane, trade name "CERATON NP", manufactured by Suzuki Industry, Co Ltd.) is impregnated into a glass cloth (trade name "E10T-4W" , thickness 100 μm, manufactured by UNITIKA CO., LTD.), and then dried at 130° C. for 5 minutes with a hot air circulation dryer to obtain a light-diffusing non-combustible composite member (glass fiber sheet-silicone resin composite). The obtained light-diffusing non-combustible composite member had a thickness of 190 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com