Method for initiating droplet fusion by liquid infiltration

A droplet and liquid technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the problems of complex droplet control process, high production cost, and damage to active substances in the production process , to achieve the effect of cost saving, simple operation and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

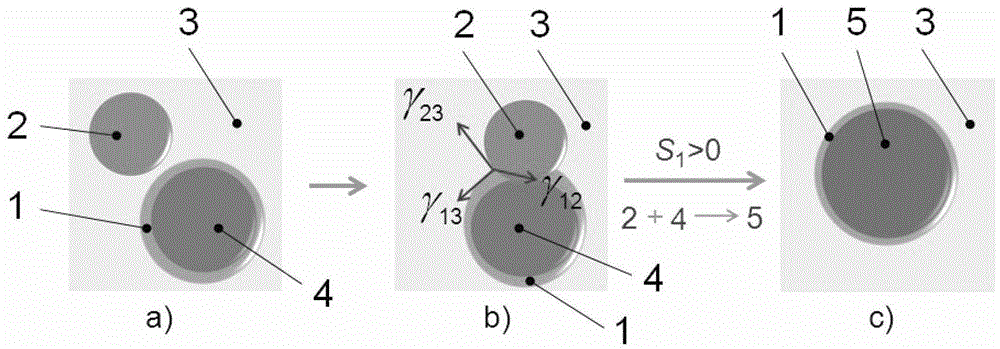

[0050] In this embodiment, liquid infiltration triggers the fusion of different droplets to achieve micro-mixing. The process steps are as follows:

[0051] (1) Prepare dispersed water phase, intermediate oil phase and continuous phase fluid

[0052] Preparation of the first dispersed water phase fluid: add sodium dodecyl sulfate (SDS) into deionized water at normal pressure and room temperature and stir evenly to form the first dispersed water phase fluid, the mass ratio of the SDS to deionized water is 0.01: 1;

[0053] The preparation of the second dispersed water phase fluid: at normal pressure, at room temperature, SDS, methylene blue are added to deionized water and stirred to form the second dispersed water phase fluid, the mass ratio of the SDS and deionized water is 0.01: 1, the described The amount of methylene blue is 2 mg per 1 ml of deionized water;

[0054] Preparation of intermediate oil phase fluid: add polyricinoleic acid glyceride (PGPR 90) and Lumogen? F R...

Embodiment 2

[0068] In this embodiment, liquid infiltration triggers the fusion of different droplets to achieve micro-mixing. The process steps are as follows:

[0069] (1) Prepare dispersed water phase, intermediate oil phase and continuous phase fluid

[0070] Preparation of the first dispersed water phase fluid: add SDS to deionized water at normal pressure and room temperature and stir evenly to form the first dispersed water phase fluid, the mass ratio of the SDS to deionized water is 0.005: 1;

[0071] Preparation of the second dispersed water phase fluid: add SDS to deionized water at normal pressure and room temperature and stir evenly to form the second dispersed water phase fluid, the mass ratio of the SDS to deionized water is 0.01: 1;

[0072] Preparation of the intermediate oil phase fluid: Add PGPR 90 into medical soybean oil at normal pressure and room temperature and stir evenly to form an intermediate oil phase fluid, the amount of PGPR 90 is 0.01 g per 1 ml of medical so...

Embodiment 3

[0080] In this embodiment, liquid infiltration triggers the fusion of different droplets to achieve micro-mixing. The process steps are as follows:

[0081] (1) Prepare dispersed water phase, intermediate oil phase and continuous phase fluid

[0082] Preparation of the first dispersed water phase fluid: add SDS to deionized water at normal pressure and room temperature and stir evenly to form the first dispersed water phase fluid, the mass ratio of the SDS to deionized water is 0.01:1;

[0083] Preparation of the second dispersed water phase fluid: add SDS to deionized water at normal pressure and room temperature and stir to form a second dispersed water phase fluid, the mass ratio of the SDS to deionized water is 0.005: 1;

[0084] Preparation of the intermediate oil phase fluid: add PGPR 90 into medical soybean oil at normal pressure and room temperature and stir evenly to form an intermediate oil phase fluid, the amount of PGPR 90 is 0.04 g per 1 ml of medical soybean oil;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com