Shaving board made of mudflat plants and manufacturing method thereof

A particleboard and tidal flat technology, used in applications, household components, flat products, etc., can solve the problems of high price, lack of wood resources, and stay in small-scale production, so as to reduce the pressure of supply and demand, save natural wood resources, and save foreign exchange expenses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

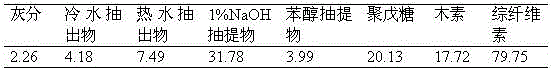

[0034] Castor stalks are used as raw materials to manufacture particleboards. Castor stalks are produced in Zibo, Shandong, with a height of 4-5m and a diameter of 5-10cm. The chemical composition is shown in Table 1. Use urea-formaldehyde resin as adhesive: urea-formaldehyde resin adhesive (UF), commercially available, with a viscosity of 50s (No. 4 paint cup), grade E1, and a solid content of 65%. Curing agent: ammonium chloride (NH 4 Cl), analytically pure, added in an amount of 1% of the solid content of the urea-formaldehyde resin. The castor stalk shavings were prepared with the same equipment as the wood shavings, and were paved manually in the laboratory. The size of the board was 300mm×300mm×10mm (length×width×thickness). The hot-pressing temperature is 150°C, the hot-pressing time is 30s / mm, the sizing amount is 12%, and the hot-pressing pressure is 315MPa. The performance of the board can meet the requirements of the national ordinary particleboard standard for int...

Embodiment 2

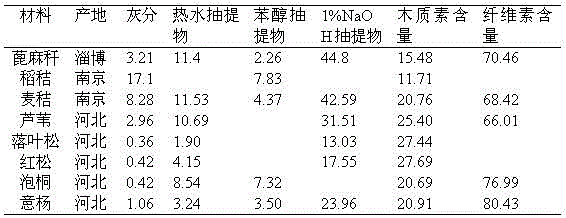

[0038]Pennisetum is used as raw material to make particleboard, hybrid Pennisetum, 2.5-3m high, 2-4cm thick stem, raw material stored for about 6 months without roots, with some leaves, grass stalk skin is blue-yellow, the main raw material is chemical The ingredients are shown in Table 2. The urea-formaldehyde resin adhesive is self-made, with a solid content of (50±2)%. Curing agent NH 4 Cl (solid). Pennisetum particleboard has a format size of 320mm×320mm and a thickness of 10mm. The hot-pressing process parameters are 13% glue, 40s / mm (board thickness) and 180°C hot-pressing temperature. The performance of the manufactured particleboard can reach the corresponding National standard requirements.

[0039] Table 2 Chemical composition of hybrid pennisetum / %

[0040]

Embodiment 3

[0042] Vetiver is used as raw material to make particleboard. Vetiver is taken from the planting base of Vetiver of Nanjing Municipal Bureau of Land and Resources, and the cut part above 20cm above the ground. The stalks are 1.7m~2.2m high, the section of the stalks is slightly flattened and cylindrical, and the long and short diameters are 0.69cm~0.83cm and 0.53cm~0.67cm on average. The leaves are 0.15cm~1.0cm wide and 30cm~130cm long. The mass ratio of stem to leaf is 1.5~2.4:1 when air-dried. The main components are shown in Table 3. The manufacturing process of particleboard is as follows:

[0043] 1) The air-dried vetiver is crushed to make shavings of a certain shape and size, and dried to a moisture content of 3% to 5%.

[0044] 2) Apply adhesive and waterproofing agent paraffin emulsion in the glue mixer, the amount of adhesive applied is 10%, and the amount of waterproofing agent applied is 1%.

[0045] 3) Hot pressing after paving with sizing shavings, the paving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com