Preparation method of amphiphilic gradient copolymer self-assembled in-situ composite silver nanoparticle

A technology of composite nanoparticles and silver nanoparticles, which is applied in the field of polymer chemistry, can solve unseen problems and achieve the effects of easy control, high stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of silver nanoparticles using PEI as a dispersion protective agent:

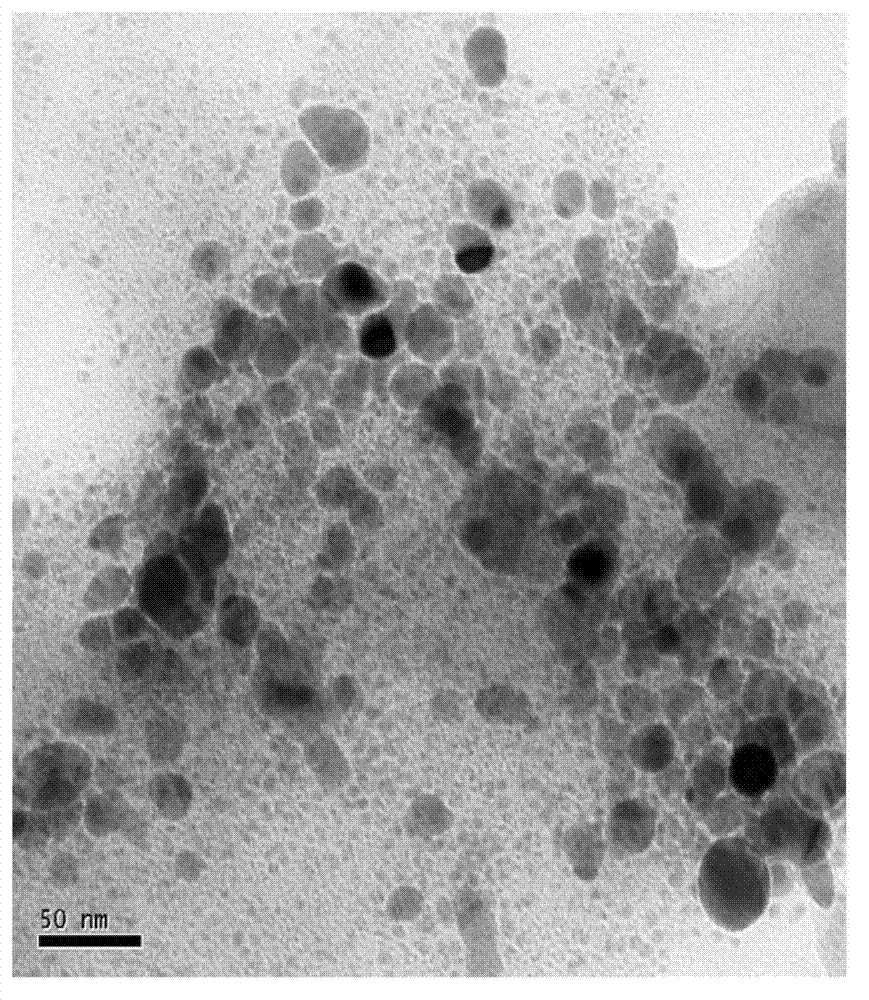

[0027] AgNO 3 Powder 0.034g dissolved in H 2 O, then add 0.2g PEI as a dispersing protective agent, stir and ultrasonically mix to prepare 200mL of oxidation solution. 0.0378gNaBH 4 Dissolve in 15mLH 2 O to obtain the reducing solution. Under constant temperature magnetic stirring, the oxidizing solution was added dropwise to the reducing solution at a rate of 30 drops / minute until the reaction was completed, and the reaction was stirred for 12 hours. Finally, the reaction solution was centrifuged at 10000r / min in a centrifuge, and the precipitate was washed twice with ethanol and acetone, and then centrifuged at a high speed again at 40 ℃ Vacuum-dried to obtain hydrophilic silver nanoparticle powder with an average particle diameter of 4.86 nm.

[0028] (2) Synthesis of amphiphilic gradient copolymer:

[0029] Add 32.8g of water and 0.463g of S-1-dodecyl-S'-[(1,3,5,7,9,11,13-hept...

Embodiment 2

[0033] Using PVP as the dispersion protection agent, the nano-silver particles were synthesized according to the method in step (1) of Example 1, with an average particle diameter of 5.02 nm. 2.16g acrylic acid (AA) and 6.72g trifluoroethyl methacrylate (TFEMA) are synthesized by the method in the step (2) of embodiment 1 the amphiphilic gradient copolymer of acrylic acid-trifluoroethyl methacrylate ( poly(AA-grad-TFEMA)), the molecular weight of the copolymer is 18000Da, and the PDI is 1.3. Then, add 0.05g of amphiphilic gradient copolymer dissolved in 5mLdioxane / 0.5mLH 2 O mixed solvent, stirred for 12h until the copolymer was completely dissolved. Add 0.005g of hydrophilic nano-silver particle powder to 3mLH 2 O, ultrasonically dispersed for 0.5h, and then stirred and mixed with the copolymer solution for 0.5h. Add 2.5mL of H2 dropwise at a rate of 5mL / h 2 O, add H for the first time 2 After the O is over, quickly add 1 mL of dioxane dissolved with 0.01 mL of dodecyl m...

Embodiment 3

[0035] Using sodium citrate as a dispersion protection agent, silver nanoparticles were synthesized according to the method in step (1) of Example 1, with an average particle diameter of 5.27 nm. 2.88g acrylic acid (AA) and 6.12g hexafluorobutyl acrylate (F 6 BA) according to the method in the step (2) of embodiment 1, synthesize the amphiphilic gradient copolymer (poly(AA-grad-F 6 BA)), the molecular weight of the copolymer is 19000Da, and the PDI is 1.3. Then, add 0.05g of amphiphilic gradient copolymer dissolved in 5mLdioxane / 0.5mLH 2 O mixed solvent, stirred for 12h until the copolymer was completely dissolved. Add 0.005g of hydrophilic nano-silver particle powder to 3mLH 2 O, ultrasonically dispersed for 0.5h, and then stirred and mixed with the copolymer solution for 0.5h. Add 2.5mL of H2 dropwise at a rate of 5mL / h 2 O, add H for the first time 2 After the O is over, quickly add 1 mL of dioxane dissolved with 0.01 mL of dodecyl mercaptan to modify the hydrophilic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com