Production technology for extracting oxytetracycline dihyclorate by utilizing hydrochloric acid and oxalic acid

A technology of oxytetracycline base and production process, which is applied in the field of production technology for extracting oxytetracycline base, can solve the problems of rising production cost of oxytetracycline base, rising price of oxalic acid, lowering competitiveness, etc., and reducing the cost of purchasing raw materials , the effect of improving market competitiveness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

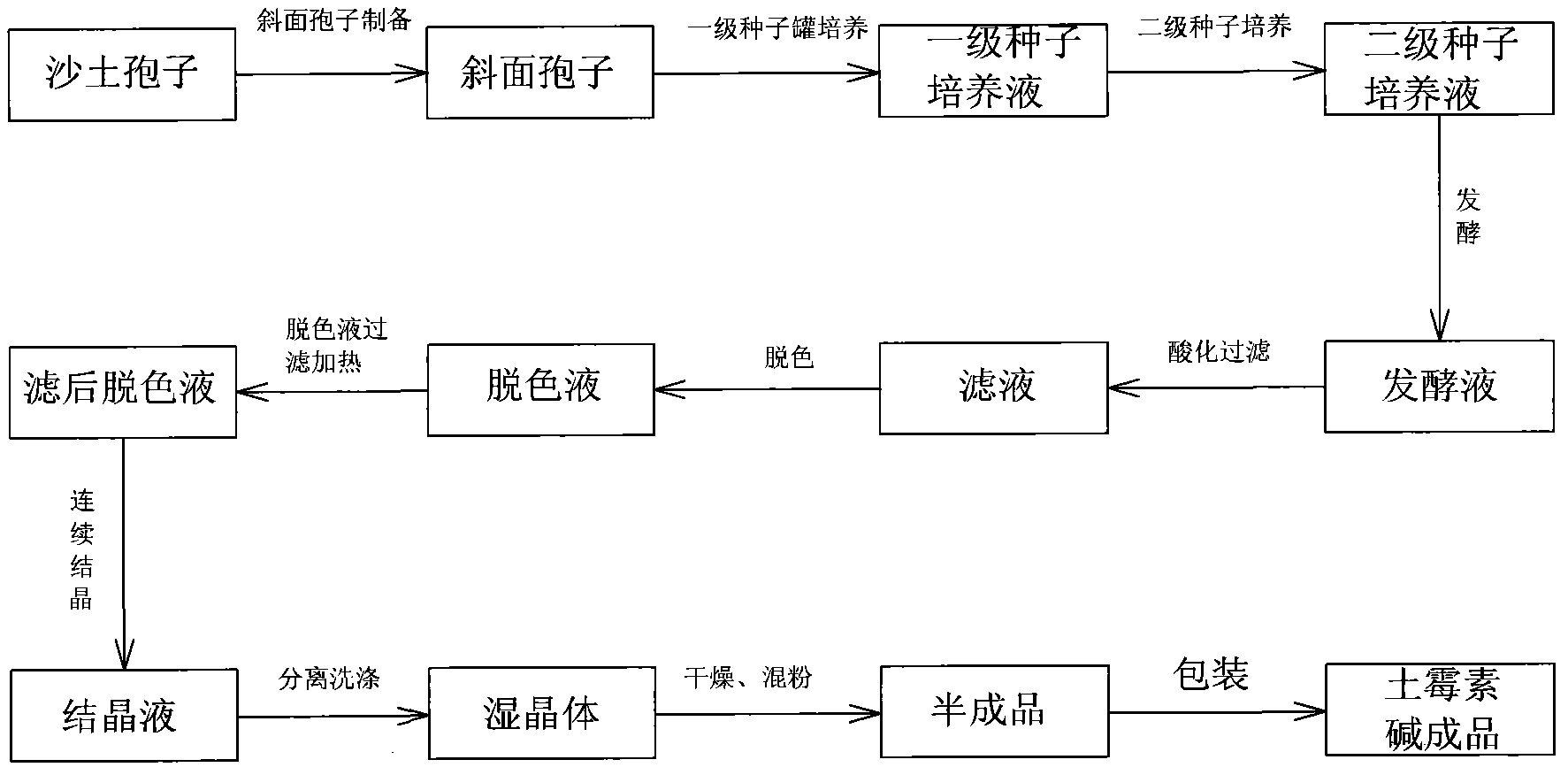

[0021] Embodiment 1: a production process for extracting oxytetracycline base by using hydrochloric acid and oxalic acid in combination, comprising the following steps: (1) fermentation; (2) acidification filtration; (3) decolorization and crystallization; (4) drying, powder mixing and packaging The finished product of oxytetracycline base is obtained;

[0022] Wherein, step (1) fermentation comprises:

[0023] a. Preparation of slanted spores: culturing spores: the slanted spores were cultured at 36°C, the humidity was 55%, and the incubation time was 96 hours;

[0024] b. Cultivation in the primary seed tank: the cultivation temperature is 30.5°C, the equipment is sealed, and the air is stirred. After about 26 hours of fermentation, it is moved into the secondary seed tank;

[0025] c. Secondary seed tank cultivation: the cultivation temperature is 30.5°C, mechanical stirring, sterile air is passed, and the fermentation is carried out for 20h and transferred to the tertiary...

Embodiment 2

[0035] Embodiment 2: a production process for extracting oxytetracycline base by using hydrochloric acid and oxalic acid in combination, comprising the following steps: (1) fermentation; (2) acidification filtration; (3) decolorization and crystallization; (4) drying, powder mixing and packaging The finished product of oxytetracycline base is obtained;

[0036] Wherein step (1) fermentation comprises:

[0037] a. Preparation of slanted spores: culturing spores: the slanted spores were cultured at 37°C, the humidity was 60%, and the incubation time was 120h;

[0038] b. First-class seed tank cultivation: the cultivation temperature is 31.5 ℃, the equipment is sealed, and the air is stirred. After about 28 hours of fermentation, it is moved into the second-class seed tank;

[0039] c. Secondary seed tank cultivation: the cultivation temperature is 31.5 °C, mechanical stirring, sterile air is passed, and the fermentation is carried out for 28 hours and then transferred to the te...

Embodiment 3

[0049] Embodiment 3: a production process for extracting oxytetracycline base by using hydrochloric acid and oxalic acid in combination, comprising the following steps: (1) fermentation; (2) acidification filtration; (3) decolorization and crystallization; (4) drying, powder mixing and packaging The finished product of oxytetracycline base is obtained;

[0050] Wherein, step (1) fermentation comprises:

[0051]a. Preparation of slanted spores: culturing spores: the slanted spores were cultured at 36.5°C, the humidity was 58%, and the incubation time was 110h;

[0052] b. Cultivation in the primary seed tank: the cultivation temperature is 31°C, the equipment is sealed, the air is stirred, and after about 27 hours of fermentation, it is moved into the secondary seed tank;

[0053] c. Secondary seed tank cultivation: the cultivation temperature is 31 °C, mechanical stirring, sterile air is passed, and the fermentation is carried out for 24h and transferred to the tertiary ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com