Preparation method of flame-retardant/super-hydrophobic cotton fabric

A super-hydrophobic, cotton fabric technology, applied in plant fibers, textiles, papermaking, fiber treatment, etc., to achieve the effects of simple process, low economic cost, flame retardancy and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

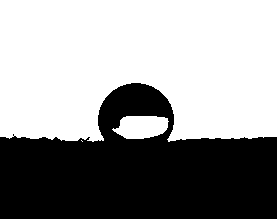

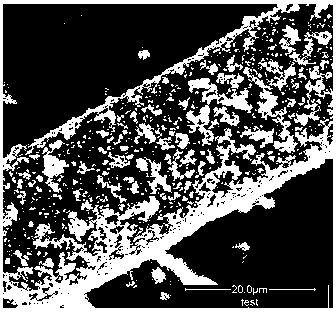

[0015] Specific embodiment one: the preparation method of the flame-retardant / superhydrophobic cotton fabric of the present embodiment is carried out according to the following steps:

[0016] 1. Clean and dry the cotton fabric;

[0017] 2. Mix 0.5~1.5mol / L sodium hydroxide aqueous solution with 0.05~0.15mol / L zinc nitrate aqueous solution, stir magnetically at 75±5℃ for 15~24h, wash with water, centrifuge, and dry to obtain nano zinc oxide particles;

[0018] 3. Use ethanol as a solvent to aminate the nano-zinc oxide particles obtained in step 2 with aminopropylmethyldiethoxysilane (the mass of zinc oxide (m) and aminopropylmethyldiethoxysilane The volume (V) ratio is 1:1~4:1, and the volume (V) ratio of ethanol is 1:100~1:150, magnetically stirred at room temperature, and the modification time is 1~3 hours to obtain aminated zinc oxide / weak;

[0019] 4. Configure acetone solution containing epoxy resin. The quality of epoxy resin is 0.5-1.5% of the volume of acetone. Imm...

specific Embodiment approach 2

[0022] Specific embodiment two: the preparation method of the flame-retardant / superhydrophobic cotton fabric of the present embodiment is carried out according to the following steps:

[0023] 1. Clean and dry the cotton fabric;

[0024] 2. Mix 0.5~1.5mol / L sodium hydroxide aqueous solution with 0.05~0.15mol / L zinc chloride aqueous solution, stir magnetically at 75±5℃ for 15~24h, wash with water, centrifuge, and dry to obtain nano oxide zinc particles;

[0025] 3. Use ethanol as a solvent to aminate the nano-zinc oxide particles obtained in step 2 with aminopropylmethyldiethoxysilane (the mass of zinc oxide (m) and aminopropylmethyldiethoxysilane The volume (V) ratio is 1:1~4:1, and the volume (V) ratio of ethanol is 1:100~1:150, magnetically stirred at room temperature, and the modification time is 1~3 hours to obtain aminated zinc oxide / weak;

[0026] 4. Configure acetone solution containing epoxy resin. The quality of epoxy resin is 0.5-1.5% of the volume of acetone. Im...

specific Embodiment approach 3

[0029] Specific embodiment three: the preparation method of the flame-retardant / superhydrophobic cotton fabric of the present embodiment is carried out according to the following steps:

[0030] 1. Clean and dry the cotton fabric;

[0031] 2. Mix 0.5~1.5mol / L sodium hydroxide aqueous solution with 0.05~0.15mol / L zinc sulfate aqueous solution, stir magnetically at 75±5℃ for 15~24h, wash with water, centrifuge, and dry to obtain nano zinc oxide particles;

[0032] 3. Use ethanol as a solvent to aminate the nano-zinc oxide particles obtained in step 2 with aminopropylmethyldiethoxysilane (the mass of zinc oxide (m) and aminopropylmethyldiethoxysilane The volume (V) ratio is 1:1~4:1, and the volume (V) ratio of ethanol is 1:100~1:150, magnetically stirred at room temperature, and the modification time is 1~3 hours to obtain aminated zinc oxide / weak;

[0033] 4. Configure acetone solution containing epoxy resin. The quality of epoxy resin is 0.5-1.5% of the volume of acetone. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com