Method for preparing activated carbon

A technology for preparing activated carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of low wear resistance of activated carbon, and achieve the effect of high wear resistance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

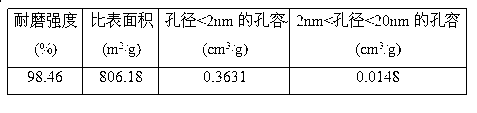

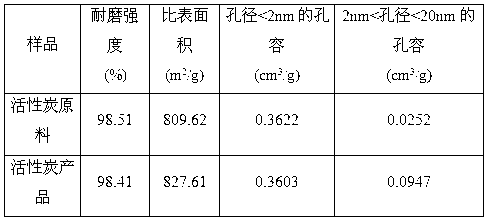

[0023] Weigh 8.8g of soluble starch (analytical pure reagent, Tianjin Guangcheng Chemical Reagent Co., Ltd.) and 3.4g of polyvinyl alcohol (average molecular weight is 2000, Shanghai Kaidu Industrial Development Co., Ltd.), add it to a 250mL conical flask, add 60g Deionized water, dissolve at 100 ° C for 2 hours; weigh 20 g of activated carbon raw materials (coconut shell activated carbon, particle size: 20-44 mesh, Shijiazhuang Hongsen Activated Carbon Co., Ltd.), add it to a triangular flask, shake well, and place at 50 ° C, Immerse in a shaking table at 120 rpm for 6.5 hours, and then dry at 150 °C for 29 hours; the dried samples are placed in a microwave high-temperature sintering furnace (HAMiLab-V3000 microwave high-temperature sintering furnace, Nanjing Xianou Instrument Manufacturing Co., Ltd.) Carbonized at 680°C for 3 hours in a nitrogen atmosphere, and then cooled in a nitrogen atmosphere to obtain 21.76 g of the product. The wear resistance, specific surface area an...

Embodiment 2

[0025] In the process of Example 2 (comparative example), no polyvinyl alcohol was added, and the prepared activated carbon had a pore volume (0.0148 cm) between 2nm3 / g) is less than the pore volume of the activity prepared in Example 1 between 2nm3 / g).

Embodiment 3

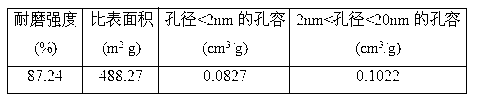

[0026] In the process of Example 3 (comparative example), no activated carbon raw material was added, and the process was to prepare activated carbon by a polymer blend carbonization method. The abrasion resistance (87.24%) of the prepared activated carbon was less than the abrasion resistance (98.47%) of the activated carbon prepared in Example 1. %).

[0027] Example 2 (comparative example)

[0028] Weigh 8.8 g of soluble starch (analytical pure reagent, Tianjin Guangcheng Chemical Reagent Co., Ltd.), add it to a 250 mL conical flask, add 60 g of deionized water, and dissolve at 100 ° C for 2 hours; weigh 20 g of activated carbon raw material (coconut shell) Activated carbon, particle size: 20-44 mesh, Shijiazhuang Hongsen Activated Carbon Co., Ltd.), add it into a conical flask, shake well, soak it in a shaker at 50°C and 120 rpm for 6.5 hours, and then dry it at 150°C for 29 hours ; The dried sample was carbonized at 680° C. for 3 hours in a microwave high-temperature sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com