Method of preparing organic fertilizer through mixed fermentation of biogas residues and biogas slurry in biogas engineering

A technology of mixed fermentation and organic fertilizer, applied in the fields of environmental protection and organic fertilizer production, can solve the problems of large water content of biogas residue, difficult solid-liquid separation, etc., and achieve the effects of improving fertility, simple operation method, and improving physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

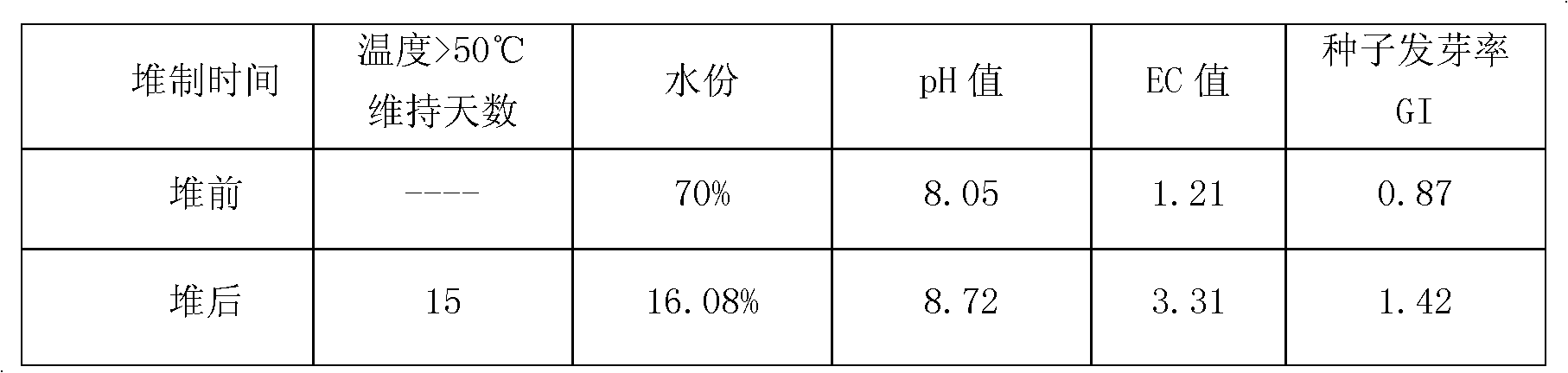

Examples

Embodiment 1

[0019] A method for preparing biogas engineering biogas residue biogas slurry mixed fermentation organic fertilizer, the steps of which are:

[0020] A. External environment of composting: It is required to prepare a greenhouse environment with a controllable temperature of 35°C. The greenhouse is required to have the conditions of a sealed environment to ensure that the moisture content and internal temperature of the heap during the composting process are not affected by the weather and other external conditions. environmental impact. In addition, the greenhouse is also required to have the condition that the roof or side plastic can be removed at any time to ensure that when the compost needs to be manually turned over for ventilation and oxygen supply, the compost can properly remove the roof when the temperature in the greenhouse (over 40°C) is too high. Make the pile body exposed to the open air environment, avoid the impact of high ambient temperature on the internal te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com