Foaming material of propylene based elastomer

A technology of propylene-based elastomers and foaming materials, which is applied in the field of foaming materials and propylene-based elastomers foaming materials. The effect of large foaming ratio and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

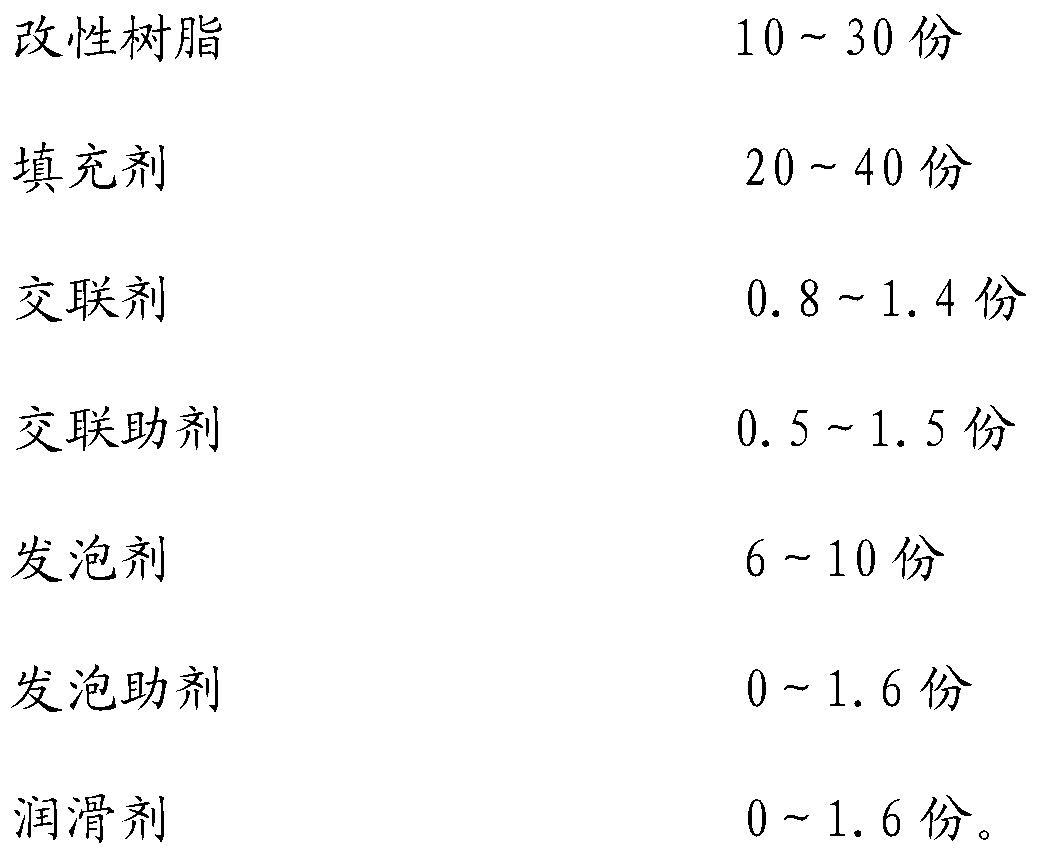

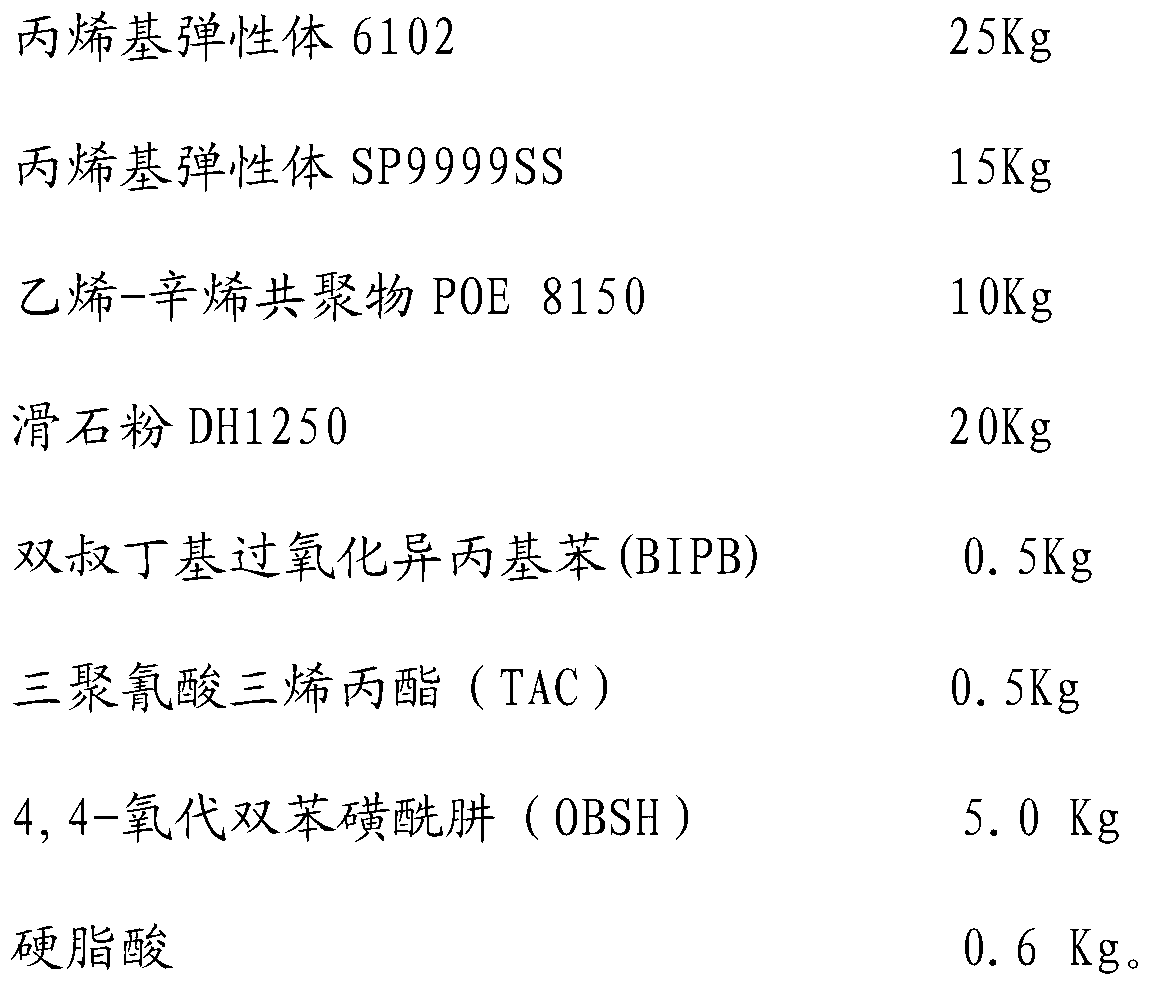

[0026] A kind of propylene base elastomer foaming material, this foaming material is made by following raw material:

[0027]

[0028] Propylene-based elastomer 6102 and PS9999SS were purchased from ExxonMobil Chemical Company; ethylene-octene copolymer POE8150 was purchased from Dow Chemical Company; talcum powder DH1250 was purchased from Youxi County Rongxin Superfine Calcium Powder Factory; Bis-tert-butylperoxycumene (BIPB) was purchased from AkzoNobel Chemical Co., Ltd.; triallyl cyanurate (TAC) was purchased from Shanghai Fangruida Chemical Co., Ltd.

[0029] This foam material adopts following preparation method to make:

[0030] 1) Propylene-based elastomer 6102, propylene-based elastomer SP9999SS, ethylene-octene copolymer POE8150, talcum powder DH1250, bis-tert-butyl peroxide cumene (BIPB), triallyl cyanurate ( TAC), 4,4-oxobisbenzenesulfonyl hydrazide (OBSH) and stearic acid were put into the internal mixer for the first mixing, the mixing time was 8 minutes, an...

Embodiment 2

[0035] A kind of propylene base elastomer foaming material, this foaming material is made by following raw material:

[0036]

[0037]

[0038] Propylene-based elastomer 6102 was purchased from ExxonMobil Chemical Company; EPDM 3722 was purchased from Dow Company; calcium carbonate 550 was purchased from Fujian Sannong Chemical Co., Ltd.; diisopropyl peroxide Benzene (DCP) was purchased from Akzo Nobel Chemicals Co., Ltd.; triallyl cyanurate (TAC) was purchased from Shanghai Fangruida Chemical Co., Ltd.

[0039] This foam material adopts following preparation method to make:

[0040] Propylene-based elastomer 6102, EPDM 3722, calcium carbonate 550, dicumyl peroxide (DCP), triallyl cyanurate (TAC), azodicarbonamide, oxidation Put zinc and stearic acid together into the internal mixer for the first mixing, the mixing time is 10min, and the mixing temperature is 120°C;

[0041] 2) Pour out the material after the first mixing, and quickly move it into the open type rubber ...

Embodiment 3

[0045] A kind of propylene base elastomer foaming material, this foaming material is made by following raw material:

[0046]

[0047] Propylene-based elastomer SP9999SS was purchased from ExxonMobil Chemical Company (produced in Singapore); ethylene-vinyl acetate (EVA) 7470 was purchased from Taiwan Formosa Plastics Company; talcum powder DH1250 was purchased from Rongxin Superfine Calcium in Youxi County powder factory; bis-tert-butylperoxycumene (BIPB), purchased from Akzo Nobel Chemicals Co., Ltd.; triallyl isocyanurate (TAIC), purchased from Shanghai Fangruida Chemical Co., Ltd.

[0048]This foam material adopts following preparation method to make:

[0049] 1) Propylene-based elastomer SP9999SS, ethylene-vinyl acetate (EVA) 7470, talcum powder DH1250, bis-tert-butyl peroxide cumene (BIPB), triallyl isocyanurate (TAIC), Azodicarbonamide, zinc oxide and stearic acid were put into the internal mixer together for the first mixing, the mixing time was 8 minutes, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com