An anti-halation and consumption-reducing coating for ultra-high voltage lines

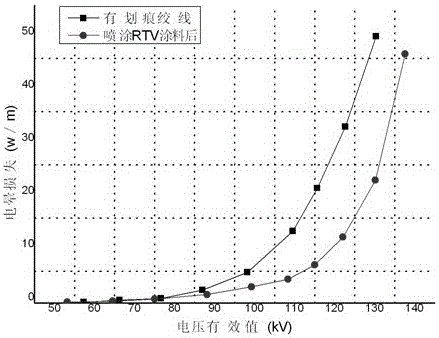

An ultra-high voltage, anti-pollution flashover coating technology, used in conductive coatings, coatings and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

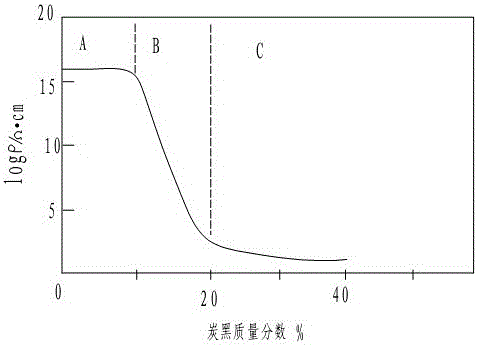

[0024] Embodiment 1, take raw material by proportioning: 20 kg of hydroxyl-terminated polydimethylsiloxane, 1 kg of silicone oil; 4.5 kg of fumed silica, 2 kg of mica powder; 3.5 kg of aluminum hydroxide, 2 kg of titanium dioxide, Methyltriacetoxysilane 1 kg, di-tert-butyldiacetoxysilane 1 kg, organotin 0.1 kg, xylene 25 kg, carbon black 22 kg.

Embodiment 2

[0025] Embodiment 2, raw materials were weighed according to the proportion: 28 kg of hydroxyl-terminated polydimethylsiloxane, 2 kg of silicone oil; 7 kg of fumed white carbon black, 2.8 kg of mica powder; 4 kg of aluminum hydroxide, and 3 kg of titanium dioxide , 3 kg of methyltriacetoxysilane, 2 kg of di-tert-butyldiacetoxysilane, 0.4 kg of organotin, 30 kg of xylene, and 30 kg of carbon black.

Embodiment 3

[0026] Example 3, raw materials were weighed according to the proportion: 22 kg of hydroxyl-terminated polydimethylsiloxane, 1.5 kg of silicone oil; 6.5 kg of fumed silica, 4 kg of mica powder; 3.1 kg of aluminum hydroxide, and 3 kg of titanium dioxide , 2 kg of methyltriacetoxysilane, 1.2 kg of di-tert-butyldiacetoxysilane, 0.3 kg of organotin, 35 kg of xylene, and 28 kg of carbon black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com